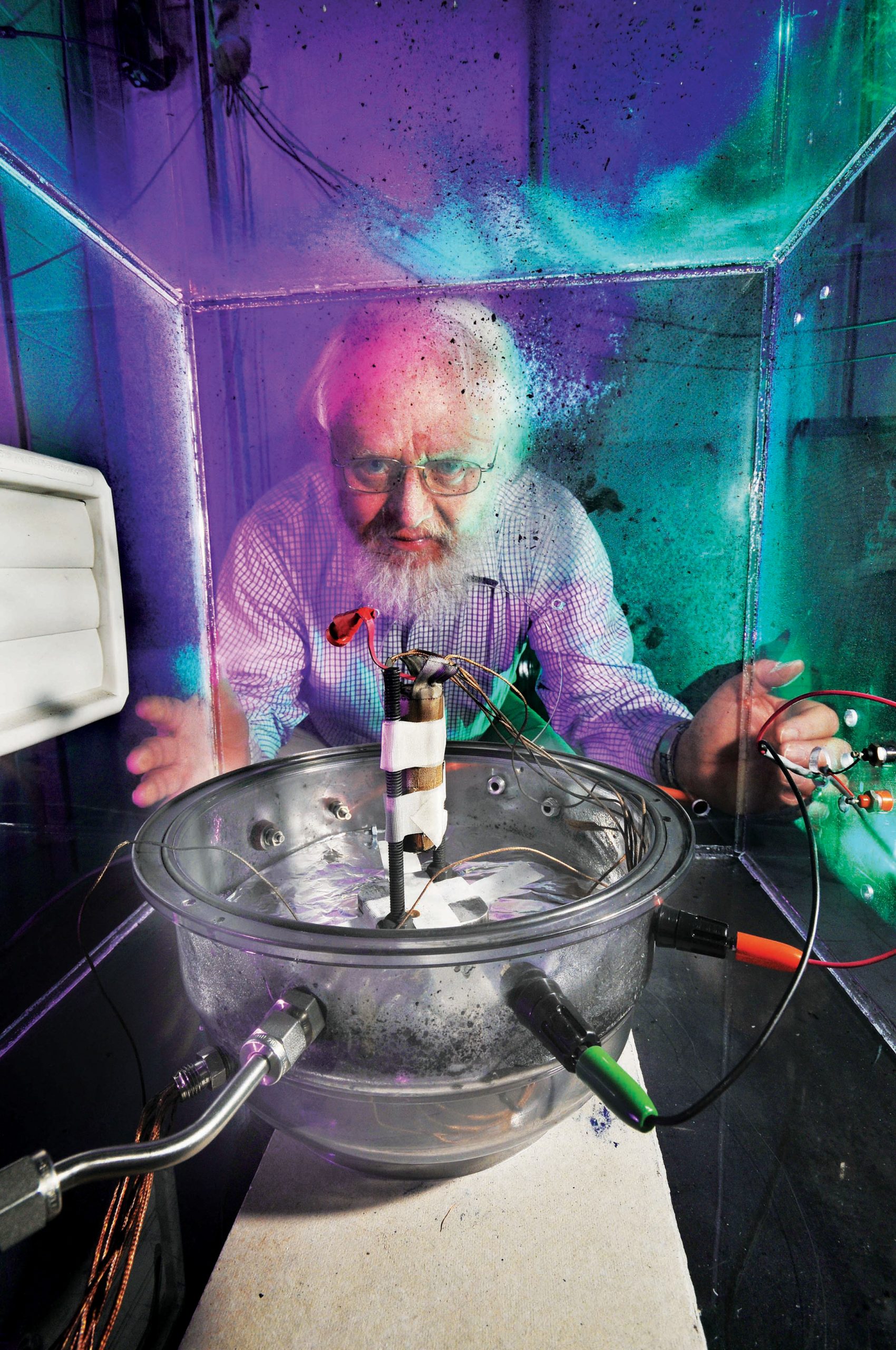

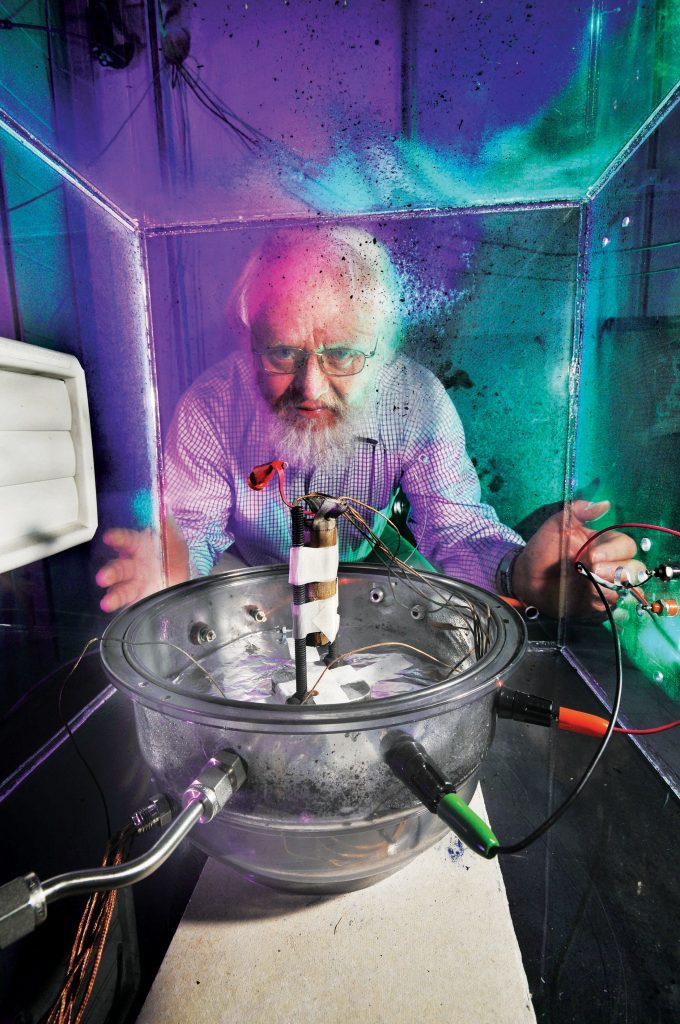

Sandia researcher Peter Roth prepares to blow up a battery to see how robust it is. The work is part of the DOE-funded FredomCAR program.

ALBUQUERQUE, N.M. — Researchers in the Power Sources R&D group at Sandia National Laboratories have been driving nails into batteries, heating them to extreme temperatures, overcharging them, and putting them into some of the most adverse conditions possible to see how much abuse they can take before they blow up.

And for certain types of lithium-ion batteries the answer is a lot.

The research is part of the DOE-funded FreedomCAR program that is looking at lithium-ion batteries to be part of hybrid electric-gasoline powered vehicles and eventually plug-in hybrids.

Current hybrid vehicles run on gasoline and use nickel-metal hydride batteries as the energy storage device for the electric motor. The intent of the battery portion of the FreedomCAR program is to replace the older type batteries with safe lithium-ion batteries that have six times the energy density of lead-acid batteries and two to three times the energy density of nickel-metal hydride batteries.

“Lithium-ion batteries, generally found in laptop computers and power tools, have greatly improved over the past few years,” says Peter Roth, lead researcher for Sandia’s FreedomCAR battery efforts. “In fact, they have improved so much that we expect to see them in hybrids later this year and possibly even in short-range plug-in hybrids within two years.”

He notes the battery industry has made great strides in manufacturing safe, long-lasting, and affordable batteries. Sandia has played a role in assuring that the lithium-ion batteries are indeed safe and can operate for long periods of time.

Sandia is a National Nuclear Security Administration (NNSA) laboratory.

One way Sandia researchers have helped determine how safe and long-lasting batteries are is by testing them in adverse situations to determine when and how they can fail or leak their electrolyte.

The Sandia research group obtains batteries and battery materials from research laboratories, like Argonne National Laboratory, and companies that manufacture and sell batteries. They then study the stability of the materials, their flame-retardant performance, high-temperature integrity of separators between the cathode and anode, and general thermophysical properties.

“We look at fundamental chemistry, wanting to discover the kinds of gases they emit when they are heated and explode,” Roth says. “We also build smaller prototype batteries that once we get the chemistry right may eventually be built full size to go into vehicles.”

Roth says that some of the newer batteries, like the new lithium/iron phosphate ones used in handheld power tools, are extremely resilient and less reactive when subjected to extreme conditions, unlike other types of batteries.

These are the type of batteries the FreedomCAR program is seeking, particularly for plug-in hybrid electric vehicles (PHEV). A PHEV is a regular hybrid that operates both on gas and a battery but has an extension cord. It can be filled with gas at the gas station and also can be plugged into any 120-volt outlet for all-electric driving. It’s almost like having a second fuel tank that is used first — only it is filled up at home.

Industry experts predict that plug-ins that can run 10 miles on all electric are two to three years away while plug-ins that can run 40 miles on all electric are three to four years away.

Plug-in hybrids make it essential that batteries be completely safe since they will be sitting in people’s garages while they recharge.

Lithium-ion batteries that will go into vehicles will be similar to computer laptop batteries. One main difference is there will be “a lot of them,” Roth says.

The first hybrids using lithium-ion batteries will be on the market later this year. Mercedes-Benz has announced that it will shortly launch the S400 BlueHybrid. After that, it will launch the S300 Bluetec Hybrid, a diesel car that is combined with a lithium-ion battery. Also, General Motors plans to introduce a 40-mile plug-in hybrid with lithium-ion batteries in 2010.