ALBUQUERQUE, N.M. — A software tool developed at the Department of Energy’s Sandia National Laboratories that automatically translates computer designs of complex products into assembly plans for use on the factory floor has been licensed to Ultramax Corporation of Cincinnati, Ohio.

Translating 3-D computer-aided design (CAD) models created by engineers into an assembly sequence for a real product often requires hundreds of trial-and-error iterations before the most efficient manufacturing plan is arrived at, a process complicated by each plant’s equipment, resources, and standards.

Sometimes parts that can be assembled electronically in the CAD world, where parts magically “fly” together, can’t be assembled in the real world where robotic tools, wrenches, or a person’s fingers are required.

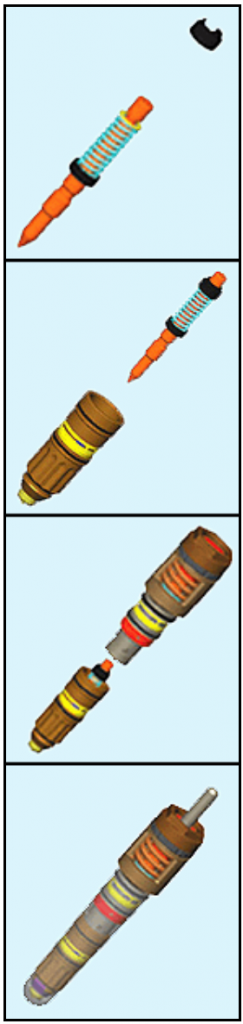

During assembly planning, process engineers often assemble, then disassemble, then reassemble groupings of prototype piece parts using various tools to arrive at a workable assembly sequence, much like someone trying to solve a 3-D puzzle.

Sandia’s ISRC ArchimedesTM software tool combines its understanding of each part’s geometry (from the CAD model) to systematically explore all possible assembly sequences for a product, automatically finding part-to-part contacts, generating collision-free insertion motions, and choosing assembly orders.

Then, based on the process engineer’s definition of tool constraints and time and cost requirements, it sorts through the possible combinations, ranks the optimum assembly sequences, and presents the results graphically.

Because each assembly sequence is generated in minutes, the user can go through as many iterations of the plan-view-constrain-plan cycle as needed to achieve an optimum plan. The resulting assembly plan is useable with the plant’s other production-planning software and processes.

Used in conjunction with other assembly planning software, the ArchimedesTM software could reduce the time required for assembly planning by up to 80 percent and will yield more efficient and cost effective plans for assembled products, according to Ultramax President Jerry Howard. (More information about Ultramax is available at www.ultramaxcorp.com.)

Translating CAD models directly to part details in assembly software is based on “feature recognition” technology that matches characteristics of a part or grouping of parts with plant operations and tools required to assemble the part. The ArchimedesTM software is among a few products now available that employ this capability.

ArchimedesTM has been under development at Sandia since the mid-1980s as a tool to translate CAD models to robot programming instructions for the assembly and disassembly of nuclear weapons and weapon components. In 1992 Sandia began to adapt the software for use on the plant floor. (For more information about the ArchimedesTM software, see www.sandia.gov/archimedes.

The license agreement gives Ultramax rights to market software products based on ArchimedesTM and Sandia patents contained in the software. Royalties will be returned to Sandia for the life of the agreement.

“The greatest compliment Sandia researchers receive is when their efforts enter the commercial marketplace,” says Patrick Eicker, Director of Sandia’s Intelligent Systems and Robotics Center (ISRC). “We are particularly pleased to have Ultramax taking the ArchimedesTM software to market.”

Sandia’s Intelligent Systems and Robotics Center provides practical, reliable robotic manufacturing solutions for a wide range of customers seeking robotic solutions in unstructured and highly variable settings. The Center’s focus is developing automation systems that are cost-effective regardless of whether the customer needs to produce 10 or 10,000 items. (For more information, see www.sandia.gov/isrc/.)