Download 300dpi JPEG image, ‘MicroPea.jpg’, 1Mb (Media are welcome to download/publish this image with related news stories.)

LIVERMORE, CA — Imagine machines with gears no bigger than a grain of pollen, fabricated thousands at a time for pennies apiece.

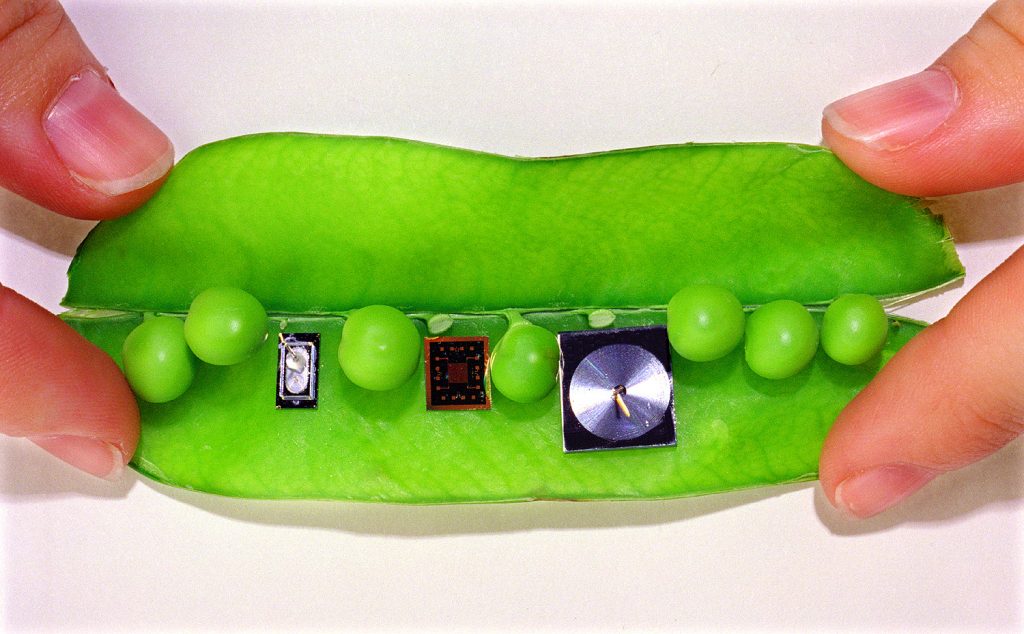

The Department of Energy’s Sandia National Laboratories is a leader in the development of microsystems, and seeks partners and contributors for research into MicroElectroMechanical Systems (MEMs) that meld traditional engineering disciplines. Current projects are being showcased to potential partners Sept. 20 at the Santa Clara Convention Center. Industry analysts estimate microsystems will have a $100 billion annual market within the next decade.

Just as the achievement of integrating circuits on a single chip enabled everything from today’s personal computer and games to modern, fuel-efficient cars and intelligent home appliances, MEMs heralds another revolution in which small, reliable, low-power devices will be able to sense, think, act and communicate.

Applications range from medical treatment and anti-terrorism to the state-of-health monitoring of engineering systems. Advances are still being pursued on many fronts — microsensors, logic circuits, micromachine fabrication and assembly, and optical or microwave communications.

Microsensors are instruments that detect their surroundings, bringing the senses of sight, smell, touch and hearing to devices. Applications include scanning the atmosphere for toxic gases.

Logic circuits contain millions of transistors with features as small as a virus, and permit devices to think and act upon what they detect.

Photonics incorporates light into microdevices by relying on the ability of compound semiconductors to efficiently emit light. Light is useful in detection schemes and in signaling a change of state.

Micromachines can be fabricated from a variety of materials. Sandia is advancing a novel plating and molding technology that uses the penetrating power of synchrotron radiation. With it, parts can be made from ceramic, polymer, and even permanent micromagnets. These cutting-edge innovations and applications will be unveiled at the show for technology experts and researchers from academia, government, and industry leaders. The event takes place from 9 a.m. to 9 p.m. on Monday, Sept. 20 at the Santa Clara Convention Center ballrooms J and K. To register, see http://www.sandia.gov/event/im/.