ALBUQUERQUE, N.M. —The ingenious system called adaptive optics, known for its computer control of subdivided, individually angled mirrors, is an efficient but expensive way to correct distortions in laser beams. The mirrors automatically adjust until an undistorted beam is obtained in a way formerly thought unachievable by a single large mirror.

Now a Sandia National Laboratories’ tool that efficiently but inexpensively uses a single mirror to achieve some of the same effects has received a U.S. patent, issued June 12.

The Sandia device, which resembles an inexpensive vise similar to those bolted to many home workshop benches, functions as a kind of poor man’s adaptive optics. It corrects optical distortions simply through pressure that changes the convexity or concavity of a single reflecting surface.

“We can’t compensate for small-scale aberrations,” says principal investigator Jens Schwarz, “but certain large-scale beam distortions are correctable with this tool.”

Sandia is a National Nuclear Security Administration laboratory.

The method already has improved the beam quality of Sandia’s huge Z-Beamlet laser, which can now fire every two hours instead of every four because the device pre-corrects for distortions caused by heat, says Schwarz.

Similar beam corrections, of course, can be achieved from tens to hundreds of thousands of dollars through traditional adaptive optics. Many small reflecting mirrors controlled by a computer can adjust in milliseconds to correct beam distortions reported by sensors farther down the line.

But for the overwhelming majority of laser users who do not need such fine control, deformation of a single mirror through convex or concave deformation applied through only a single actuator may be the ticket, especially when the price is expected to be only a few thousand dollars.

Commercial interest in the inexpensive device already has been expressed.

A reverse use of the technique could deliberately focus the beam to interrogate points of distant interest. This use would detect chemical or biological agents introduced at battlefields many miles away, a technique called laser-induced fluorescence spectroscopy. “Because the mirror can change the focus of a laser beam quickly and rapidly, a laser beam could interrogate molecules at a variety of distances and the results would be visible through backscattered light,” Schwarz says.

Coping with distortions in the beam itself

Distortions happen when new energies are injected in the lasing system to create more powerful beams. These injections are achieved by racks of lamps that flare briefly, like old-fashioned photographic flashbulbs, sending an energy pulse into the laser medium of doped glass in which the beam is forming.

When the laser beam traverses the doped glass, it stimulates the material to release energy that adds to the beam’s strength, an effect known as gain. But the exterior of the doped glass — closer to the flashlamps — is unavoidably heated more than its interior. This modifies its refractive index, focusing the beam to a point some meters away instead of allowing it to continue to infinity.

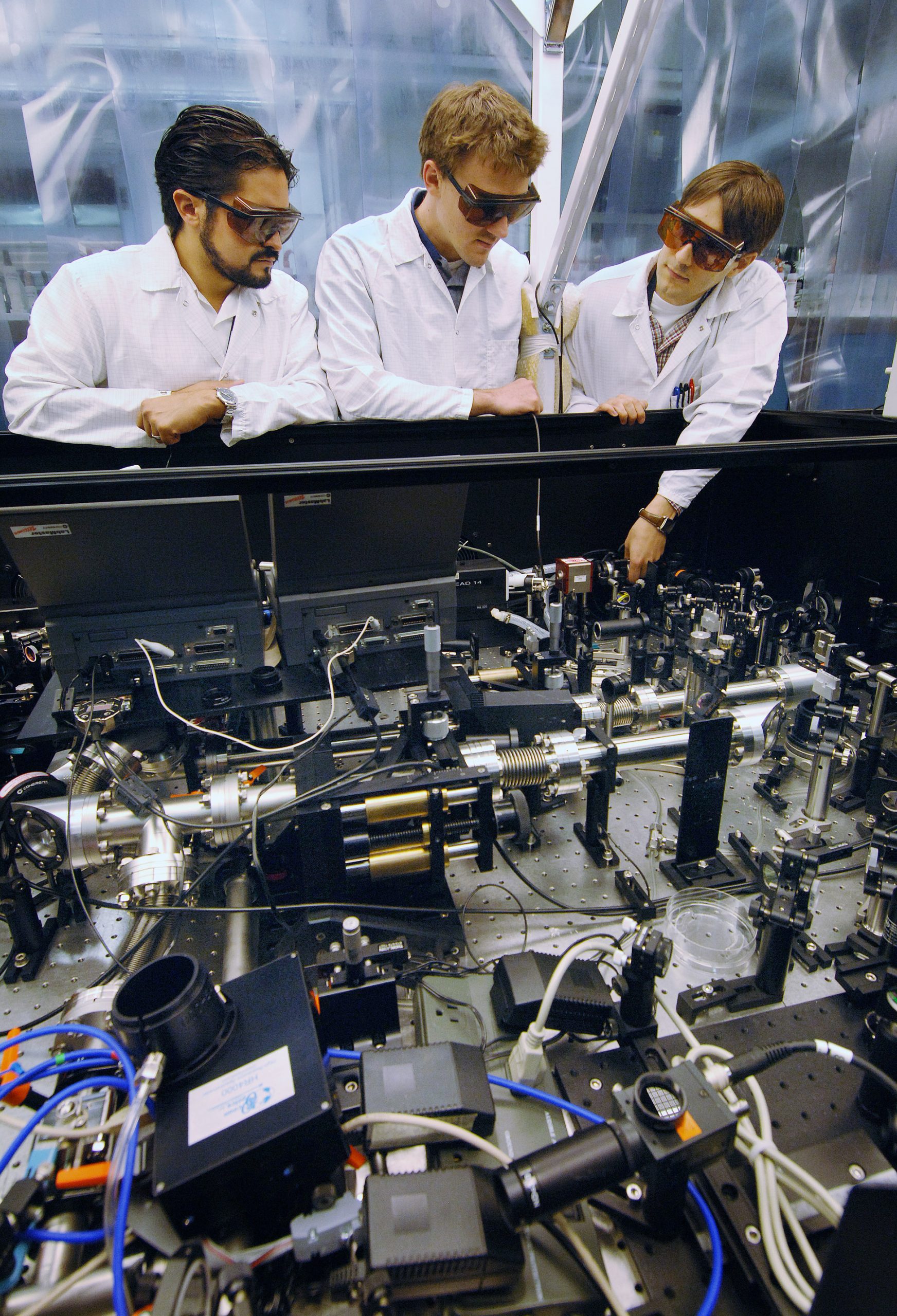

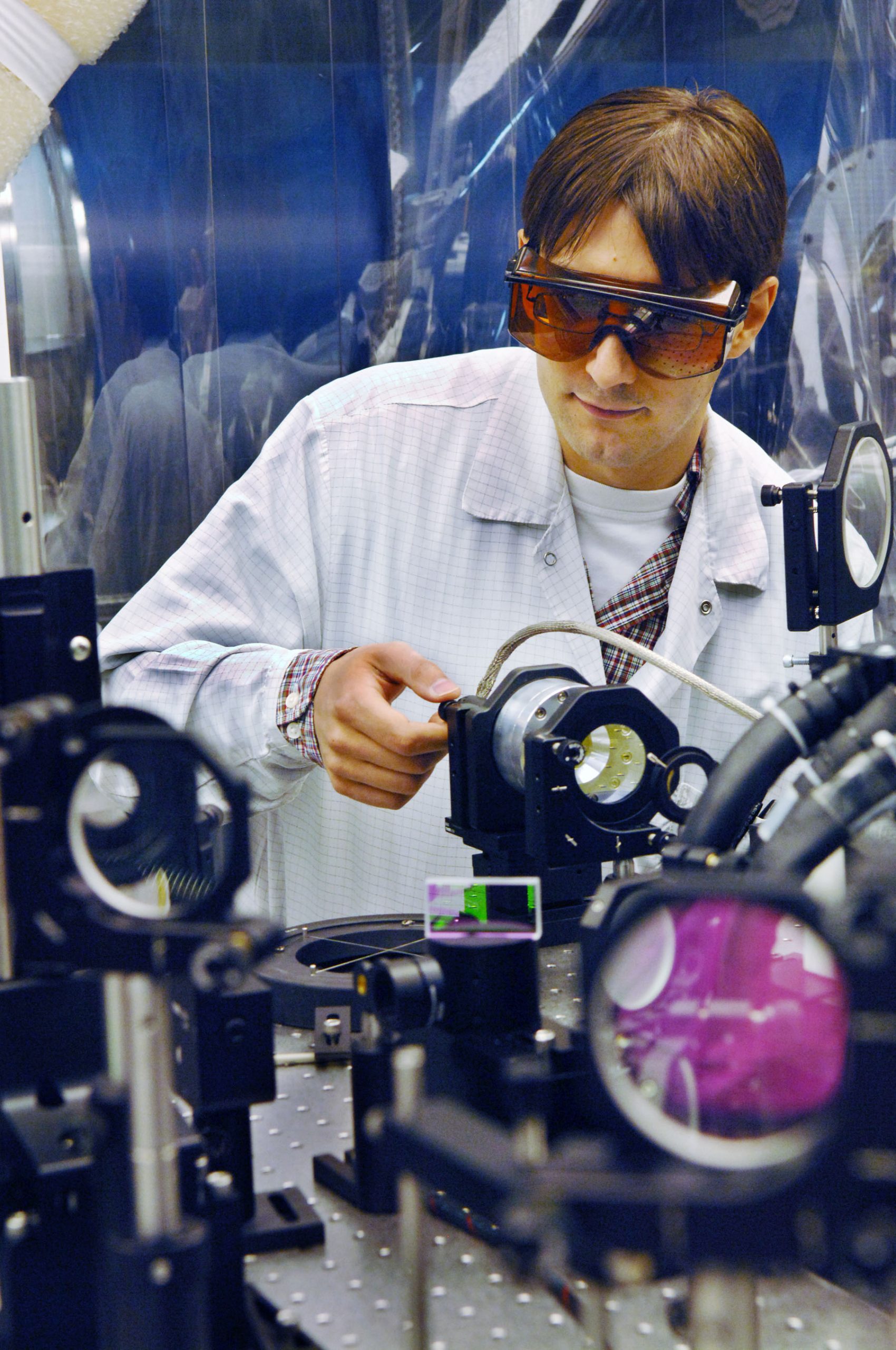

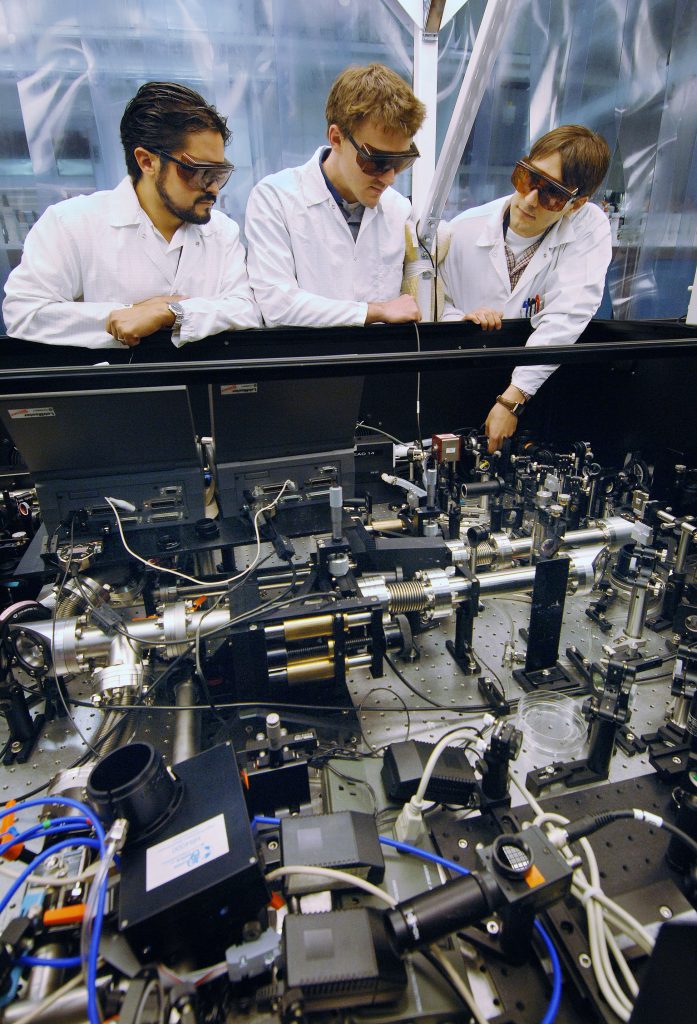

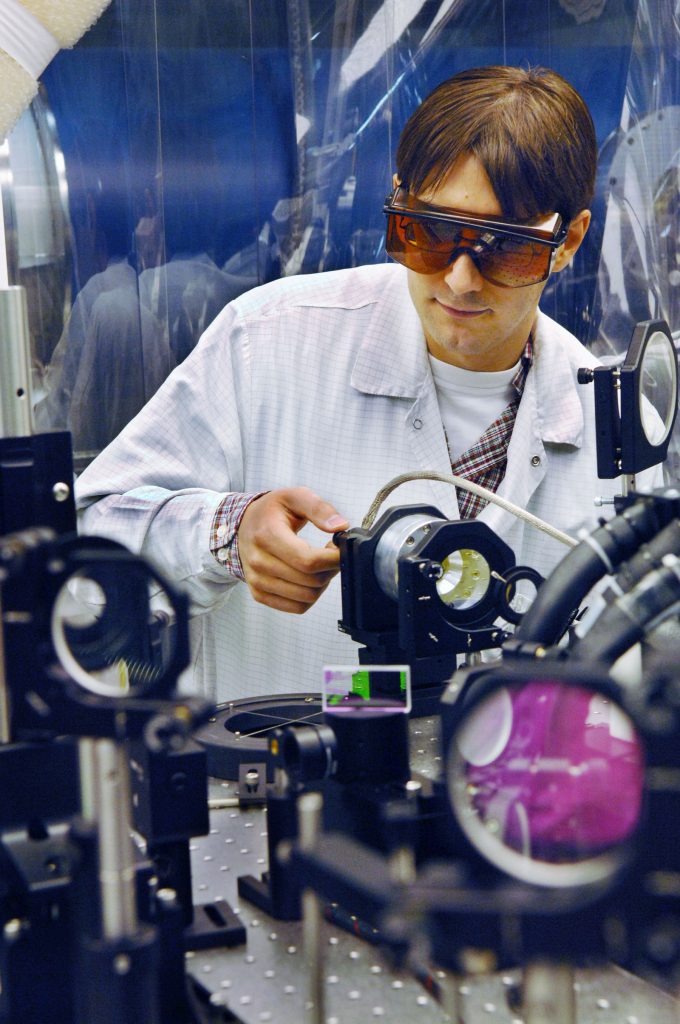

Rather than alter the flashlamps or gain medium, Schwarz with the aid of Marc Ramsey and Daniel Headley used a single flexible mirror to pre-correct for the distortion to take place later in the beam’s passage.

The corrective effect is achieved by placing a flat mirror between two concentric rings of different sizes, one stationary and the other free. A screw-drive turned either by fingertips or by motor (the motor raises the price) applies a force to the free ring and bends the mirror a few microns, changing its focal length. The orientation of the large and small rings determines whether the distortion is concave or convex.

The method has been shown to work over a wide range of laser beam energies ranging from 30 millijoules to 500 joules.

The motivation for the work, says Schwarz, is that “It’s customary to use a static concave mirror — or a combination of appropriate lenses — and hope it’s correcting well for distortions in the lensing system you have. But rather than buy a succession of lenses or mirrors, we thought: Let’s see if we can do the job more simply and inexpensively by using only one mirror with a flexible focal length.”

Descriptions of the work and its applications have been published in the February 2006 Applied Physics B: Lasers and Optics and the November 2006 Optics Express. Other authors in addition to Schwarz, Ramsey and Headley include Ian Smith and John Porter.

The device, listed as a “Variable Focal Length Deformable Mirror” will issue as U.S. Patent No. 7,229,178.