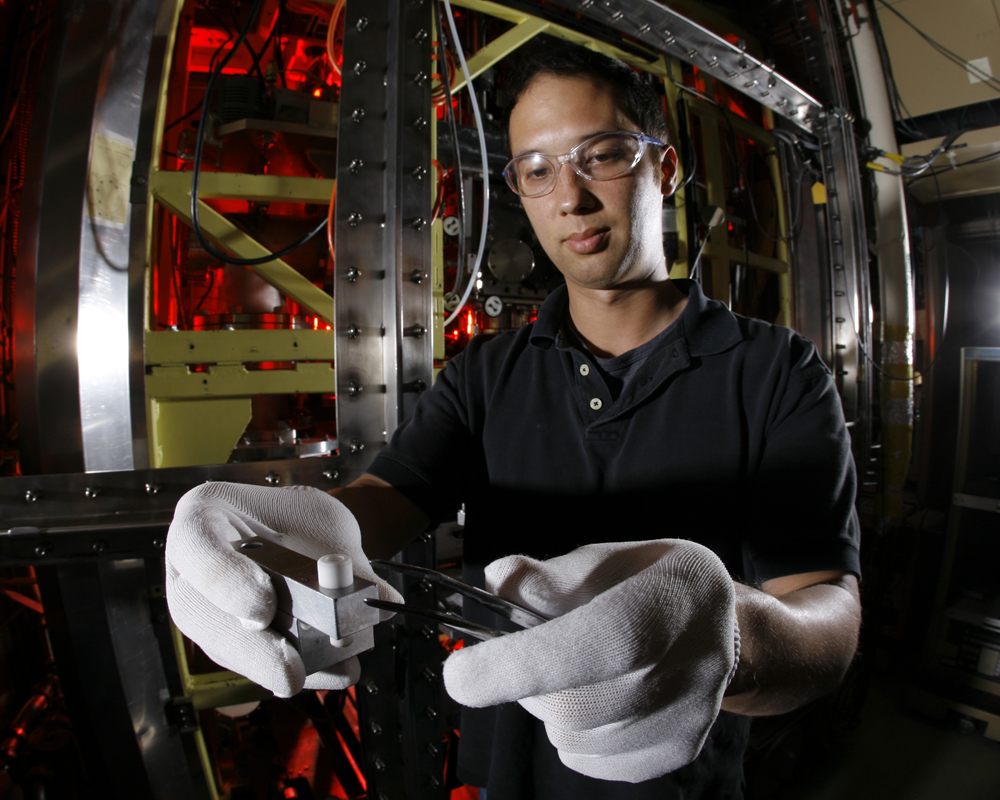

(Photo credit: Randy Wong)

LIVERMORE, CALIF. —Sandia researchers have spent a good deal of time in recent years examining the viability of hydrogen storage materials through the Department of Energy (DOE) Metal Hydride Center of Excellence (which it leads), as well as a work for others (WFO) partnership with General Motors, and other related materials science projects. The storage of hydrogen on board automobiles is a challenging issue, and hydrogen storage materials continue to be one of the more promising solutions under consideration.

In addition to developing materials that can store sufficient densities of hydrogen, an important area of research is the reactivity and durability of materials. How exactly do these storage materials behave under various conditions, including exposure to water and other compounds? What are the best methods to produce and handle hydrogen storage materials?

By addressing these questions now, researchers aim to ensure that such research and development issues are exhaustively examined and resolved for consumers prior to the commercialization and deployment of new storage technologies. Now, thanks to a new DOE-funded project at Sandia led by principal investigator Daniel Dedrick, the material properties of advanced metal hydrides within the context of an automotive fuel tank system are being quantified.

Sandia is a National Nuclear Security Administration laboratory.

Dedrick, a mechanical engineer, has worked on the Sandia/GM work-for-others project for several years, participates in the International Energy Agency’s task on hydrogen storage, and has become an expert on metal hydride-based hydrogen storage systems. Consequently, he was well positioned to lead a proposal when the DOE decided to select six new competitively awarded projects in applied hydrogen storage research at more than $8 million. Daniel’s proposal, developed with colleagues Rich Behrens, Bob Bradshaw, Rich Larson, and Michael Kanouff, was selected for a 3-year, $2 million effort (other storage projects were awarded to Argonne National Laboratory, Miami University, United Technologies Research Center, and the University of Hawaii).

(Photo credit: Randy Wong)

“I realized when we all got together for the first time that there was some 167 years of Sandia service represented around the table,” says Dedrick, who has been with Sandia for some seven years. “It was exhilerating.” Dedrick says the mix of talent and experience on his team, which also includes Ken Stewart, Greg Evans, and Aaron Highley, will make it a success.

Although researchers, including those at Sandia, have been studying hydrides for years, the reaction processes between hydrogen storage materials (such as metal hydrides) and other materials, such as water, need to be better understood. This new project will aim to develop generalized methods and procedures required to quantify the reactivity properties of hydrogen storage materials to enable the optimal design, handling, and operation of hydride-based hydrogen storage systems for automotive applications. Through experiments and by building and validating models, the team is expected to develop computational tools that can predict the reaction processes.

The first task, Dedrick says, will be to create a reaction model on a very small scale that begins to reveal how a hydride sample will behave under specific conditions. Eventually, the work will reach larger scales, but only after researchers have made educated conclusions based on experimental validation of the initial models.

In addition to the Sandia team members, the lab is coordinating with two other DOE-funded efforts – Savannah River National Laboratory and United Technologies Research Center. The three are active participants in the International Partnership for the Hydrogen Economy (IPHE), a global consortium established in 2003 to accelerate the transition to a hydrogen economy.

Dedrick says the project’s research will eventually be transitioned to DOE’s and Sandia’s codes and standards work. “Eventually, when there is a comprehensive guide on how to operate a hydrogen filling station, there will need to be a chapter on dealing with hydrogen storage materials. This work will provide a scientific basis for the optimal operation of systems containing hydrogen storage materials.”