Download 150dpi JPEG image, ‘satelli.jpg’, 675K

ALBUQUERQUE, N.M. — Fewer failures in satellites used for everything from communications to surveillance may be the result of bipolar electronics reliability tests developed by Sandia National Laboratories, a Department of Energy (DOE) national security research lab, and a consortium headed by the Defense Special Weapons Agency (DSWA).

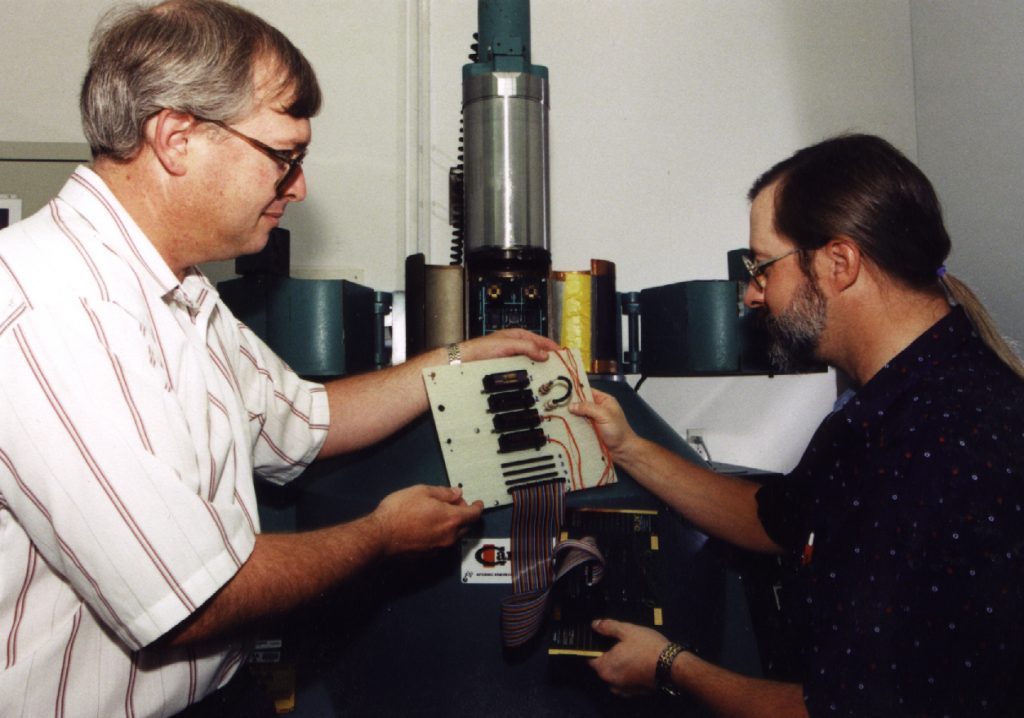

A Sandia team led by Dan Fleetwood, a physicist in the Radiation Technology and Assurance Department, and colleague Peter Winokur helped to develop the tests to determine how well bipolar electronics — commonly used for analog signal processing in satellites — can survive long-term radiation exposure in space. The American Society for Testing of Materials (ASTM), an agency that sets test standards for the electronics industry, adopted the tests earlier this year as the official test standards for satellite electronics parts.

Some systems have already benefited from the test standards. For example, one manufacturer has reconfigured its system design to avoid potential failures in a critical bipolar voltage regulator that was identified using this screening procedure.

“Satellite system designers are paying a lot of attention to these problems now in the design phase of their systems,” Winokur says. “When a satellite fails in space, it’s hard to send a repair crew to see what broke. You need to put in parts as reliable as possible from the beginning to prevent future problems.”

Bipolar electronics found in many satellites are commercially manufactured without special consideration for their possible application in space. Until 1991, it was generally thought that bipolar electronics could withstand radiation exposure on the basis of testing performed by satellite manufacturers.

“The electronics were tested using high doses of radiation delivered in short times at room temperature, and they functioned just fine under those circumstances,” Fleetwood says. “Many parts easily survived testing to levels of radiation well past the point where people would be concerned, and it was thought that the longer times over which the doses would be delivered in space would only improve their response due to self-healing effects.”

Startling discovery

But confidence in bipolar electronics’ reaction to long-term radiation began to erode seven years ago following a startling discovery by researcher Ed Enlow of Mission Research Corp. in Albuquerque. Using a standard radiation test developed at Sandia and DSWA for CMOS (complementary metal oxide semiconductor) electronics — which are different from bipolar electronics — he found that bipolar electronics failed prematurely at considerably lower radiation levels than laboratory testing would suggest.

The problem was that the active “base” region of the bipolar transistor typically is covered by a thick layer of insulation that is adequate for performance in applications like consumer or automotive electronics where there is no radiation exposure, or even in some environments where radiation exposure occurs so rapidly that the amount of damage to the device is limited by radiation-induced space-charge screening within the insulator. At the lower dose rates encountered in space this protective charging effect does not occur, and the active base of the transistor is damaged. These results have been described in a series of papers at the annual Institute of Electrical and Electronic Engineers (IEEE) Nuclear and Space Radiation Effects conference by Fleetwood, Winokur, and colleagues from Vanderbilt, The Aerospace Corporation, and other members of the DSWA consortium.

“Because of Sandia’s 40-year history in radiation effects testing, the DSWA tapped the Labs to explore tests to determine if bipolar electronics could withstand long-term radiation exposure,” Winokur says.

Challenge to predict response

The challenge was to come up with tests that would predict a 10-year response in a few weeks. “We do this by irradiating components in three ways,” Fleetwood says. “First, we zap them quickly with high doses of radiation at room temperature, taking only a few hours. We compare their response to a second group that receives the same dose of radiation delivered over a few weeks. And we also compare them to a group that receives a high dose of radiation at higher temperatures. By combining the information, we were able to come up with a simple screening procedure that satellite manufacturers can do themselves to determine the reliability of the parts they are putting into their systems.”

Sandia’s work on the test development is funded primarily by the DSWA and is part of a consortium made up of the DSWA, RLP Research, Mission Research Corp., Naval Surface Warfare Center-Crane, Jet Propulsion Laboratory, The Aerospace Corporation and Vanderbilt University.

Specific individuals from these groups making critical contributions to the development, refinement, and acceptance of tests were Ron Pease, RLP Research; Vanderbilt University professor Ron Schrimpf and students; Steve Witczak, The Aerospace Corporation; Alan Johnston, JPL; Tom Turflinger and Dave Emily, NSWC Crane; Lew Cohn, DSWA; and Dennis Brown, Naval Research Laboratory.

Technical contact:

Dan Fleetwood, dmfleet@sandia.gov, (505) 844-1825