Download 300dpi JPEG image, ‘sensor_fieldtest.jpg’, 400K (Media are welcome to download/publish this image with related news stories.)

ALBUQUERQUE, N.M. — A real-time gas- and water-quality monitoring system that consists of a miniature sensor array packaged in a weatherproof housing developed by the Department of Energy’s Sandia National Laboratories may become one tool in the effort to protect the nation’s water supply. (See ‘Sandia develops program to assess water infrastructure vulnerabilities’ at https://newsreleases.sandia.gov/sandia-develops-program-to-assess-water-infrastructure-vulnerabilities/.)

“The electronic sniffer is a unique monitor that can be put directly underground — in groundwater or soils where the humidity reaches nearly 100 percent — and detect toxic chemicals at the site [in-situ] without taking samples to the lab,” said researcher Cliff Ho. “It has the capability of detecting in real time undesirable chemicals being pumped into the water supply accidentally or intentionally. It will be able to monitor sites containing toxic chemical spills, leaking underground storage tanks, and chemical waste dumps, potentially saving millions of dollars a year in the process.”

Traditional monitoring methods for contaminated sites usually involve physically collecting water, gas, or soil specimens at the location and taking them to a laboratory for analysis. This can become extremely expensive, with each sample analysis costing between $100 to $1,000. In addition, the integrity of off-site analysis can be compromised during sample collection, transport, and storage.

The monitoring system developed by Ho and colleague Bob Hughes is designed to be left at the site. It would send back information in real time on solvents present and their concentrations to a data collection station where information would be downloaded and analyzed. Telemetry methods can also transmit data wirelessly from remote stations to a computer that would upload information to an interactive web site, providing immediate access to authorized individuals anywhere in the country.

Download 300dpi JPEG image, ‘Sensor_casing.jpg’, 144K (Media are welcome to download/publish this image with related news stories.)

Chemiresistor at the heart

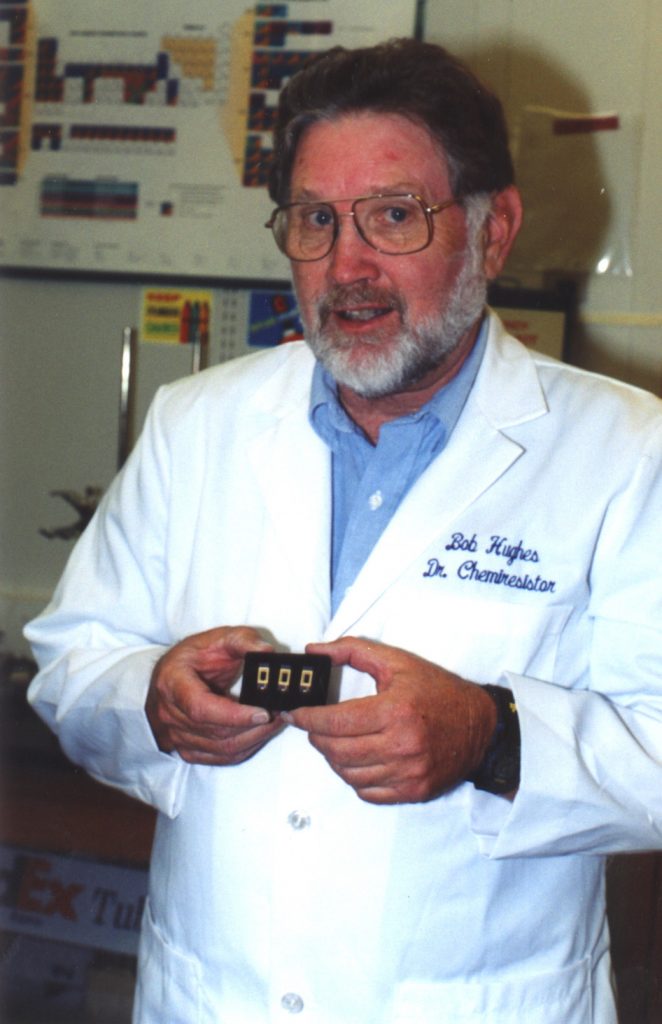

The heart of the device is an array of differing miniature sensors that can detect volatile organic compounds (VOCs). Called a chemiresistor, each polymer-absorption sensor is fabricated by mixing a commercial polymer dissolved in a solvent with conductive carbon particles. The ink-like fluid is deposited and dried on wire-like electrodes on a specially designed microfabricated circuit. When VOCs are present, the chemicals absorb into the polymers, causing them to swell. The swelling changes the electrical resistance that can then be measured and recorded. The amount of swelling corresponds to the concentration of the chemical vapor in contact with the polymers.

The polymers will shrink once the chemical is removed, reverting the resistance to its original state.

“By using four different kinds of polymers — one for each sensor — we think we can detect all solvents of interest,” says Hughes, who developed the sensors for the project.

The array of differing sensors can be used to identify different VOCs by comparing the resulting chemical signatures with those of known samples.

Waterproof package

But it’s the way the sensors are packaged that allows the device to be placed in water or underground. The protective package surrounding the chemiresistor chip designed by Ho and other team members is small — about three centimeters in diameter — and is designed to be rugged and waterproof while allowing the chemiresistors to be exposed to VOCs in both aqueous and gas phases. Recent versions of the housing have been constructed of stainless steel.

“The package is modular like a water-tight flashlight and is fitted with o-rings,” Ho says. “It can be unscrewed, allowing for easy exchange of components.”

Download 300dpi JPEG image, ‘Bob_Hughes.jpg’, 352K (Media are welcome to download/publish this image with related news stories.)

Another unique feature of the packaging is that it has a small “window” covered by a GORE-TEX® membrane to maintain a waterproof seal. Like clothing made of GORE-TEX, it repels liquid water but “breathes,” allowing vapors to diffuse across the membrane. If the device is immersed in contaminated water, VOCs dissolved in the water will partition across the membrane into the gas phase, where they are detected by the chemiresistors.

Inside the packaging the chemiresistors are placed on a 16-pin dual inline package connected to a long weatherproof cable. The cable then can be connected to any data logger. Since only DC measurements are being made, the cable can be almost any length.

The research team plans several field tests of the device. It was recently deployed at Sandia’s Chemical Waste Landfill where data will be recorded for at least several weeks to several months to determine how the chemiresistor sensors perform in a real in-situ environment. The sensor is suspended about 60 feet down a screened well that has a depth of about 500 feet to the water table, logging data every hour.

Ho hopes to learn from this field test the longevity of the sensor and the importance of temperature variations, barometric pressure changes, and ground humidity.

Future tests are planned at Edwards Air Force Base and the Nevada Test Site.

“Over the next few years I expect we will see this invention being applied to DOE sites that require monitoring, remediation, and/or long-term stewardship of contaminated sites, which currently spend millions of dollars for off-site analysis of manual samples,” Ho says. “This device can also be applied to numerous commercial sites and applications, such as gas stations, which include more than two million underground storage tanks that require monitoring to satisfy EPA requirements.”

Sandia Technical contacts:

Cliff Ho, ckho@sandia.gov , (505) 844-2384

Bob Hughes, rchughe@sandia.gov (505) 844-8172