ALBUQUERQUE, N.M. —Networks of sensors mounted on commercial aircraft might one day check continuously for the formation of structural defects, possibly reducing or eliminating scheduled aircraft inspections.

Like nerve endings in a human body, in situ sensors offer levels of vigilance and sensitivity to problems that periodic checkups cannot, says Dennis Roach, who leads a Sandia National Laboratories team evaluating some of the first sensor systems for aircraft.

“With sensors continually checking for the first signs of wear and tear, you can restrict your maintenance efforts to when you need human intervention,” he says.

Structural health monitoring, or SHM, techniques are gaining the support of airframe manufacturers, airlines, and regulators, he says.

SHM incorporates into the aircraft structure itself nondestructive inspection (NDI) technologies currently used in manual inspections — to scan for small cracks in the airframe, for example. Such inspections are strictly regulated to maintain a high degree of aircraft safety.

Widespread adoption of SHM could significantly reduce maintenance and repair expenses for commercial aircraft, now estimated at about a quarter of the fleet’s operating costs, says Roach. Those costs are rising as the aircraft age, many well beyond their design lifetimes.

Ground crew technicians might plug a laptop or diagnostic station into a central port on the aircraft to download structural health data. Eventually “smart structures” fitted with many sensors could self-diagnose and signal an operator when repairs are needed.

Ultimately an integrated network of sensors could monitor not only structural elements, but also the health of electronics, hydraulics, avionics, and other systems.

Sandia is a National Nuclear Security Administration laboratory.

Extension of NDI

The SHM sensors being developed or evaluated at Sandia can find fatigue damage, hidden cracks in hard-to-reach locations, disbonded joints, erosion, impact damage, and corrosion, among other defects commonly encountered in aging aircraft.

The work is an extension of Sandia’s Airworthiness Assurance Program, which for years has focused on development and evaluation of NDI technologies to aid human inspectors as they go over an aircraft frame or fuselage skin inch by inch looking for the consequences of aging.

Boeing’s recent incorporation of an in situ, or permanently-mounted, crack-detection sensor into its NDI standard practices manual for Boeing airframes is the first time a manufacturer has adopted SHM techniques — evidence that the industry is ready to consider new ways of ensuring the safety of aircraft beyond NDI-assisted human inspection, says Roach.

Several other commercial airlines working with Sandia are considering SHM applications and are working with Boeing and the Federal Aviation Administration (FAA) to use embedded crack detection sensors to address specific maintenance requirements.

“When we set out to do NDI, in the back of our minds we knew that eventually we wanted to create smart structures that ‘phone home’ when repairs are needed or when the remaining fatigue life drops below acceptable levels,” he says. “This is a huge step in the evolution of NDI.”

Growing demand

Sandia is part of a group formed in November 2006 — the Aerospace Industry Steering Committee for Structural Health Monitoring — to address the growing demand from the aerospace industry for standardized procedures and certification requirements for SHM. The international group includes manufacturers, regulators, government agencies, the military, universities, and Sandia.

The Sandia team already has developed or evaluated several types of inexpensive, reliable sensors that can be mounted on aircraft structures, typically where flaws are expected to form. “If I usually get fatigue damage in this area above a door, that’s where I am going to install a crack detection sensor,” Roach says.

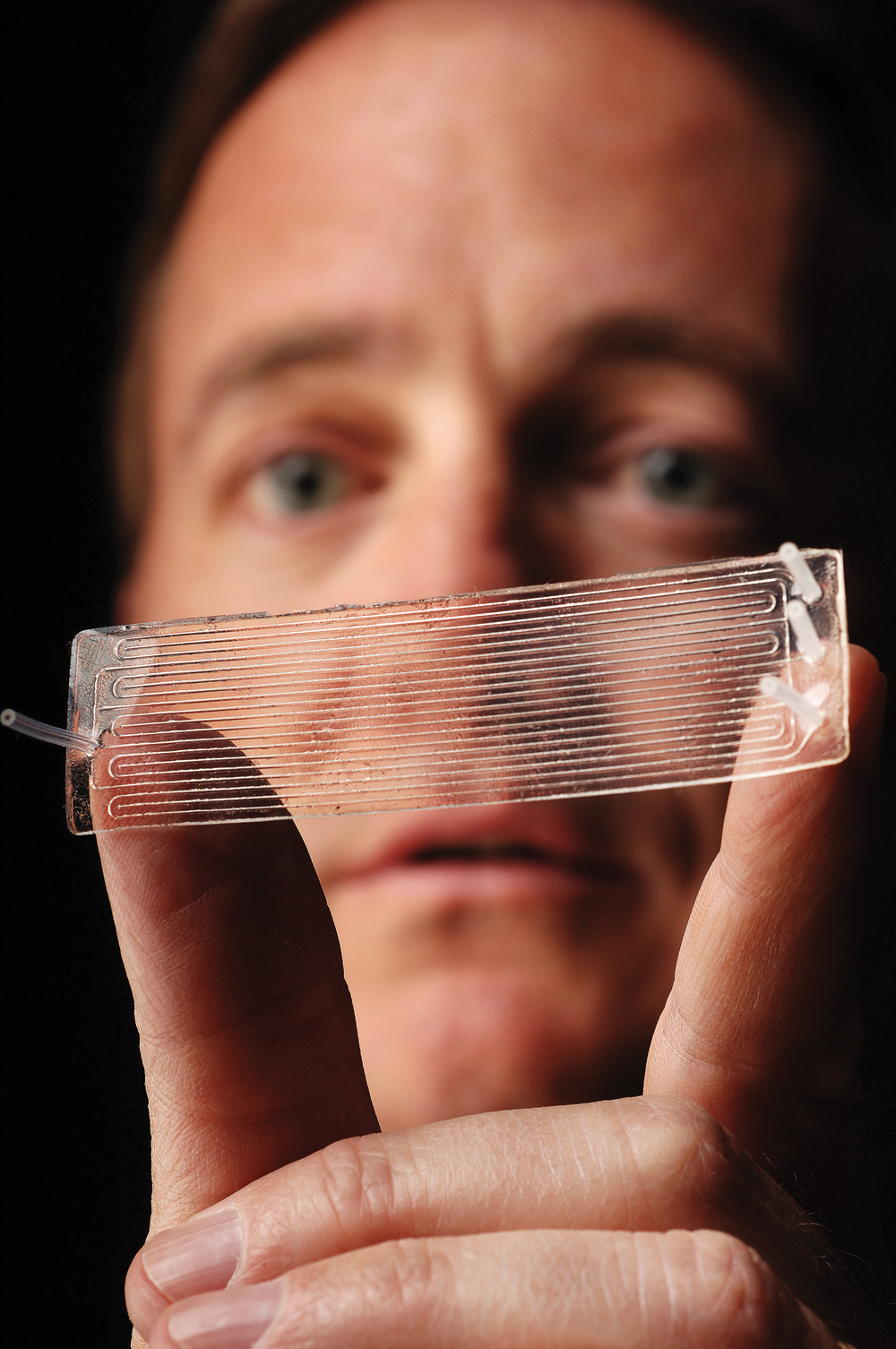

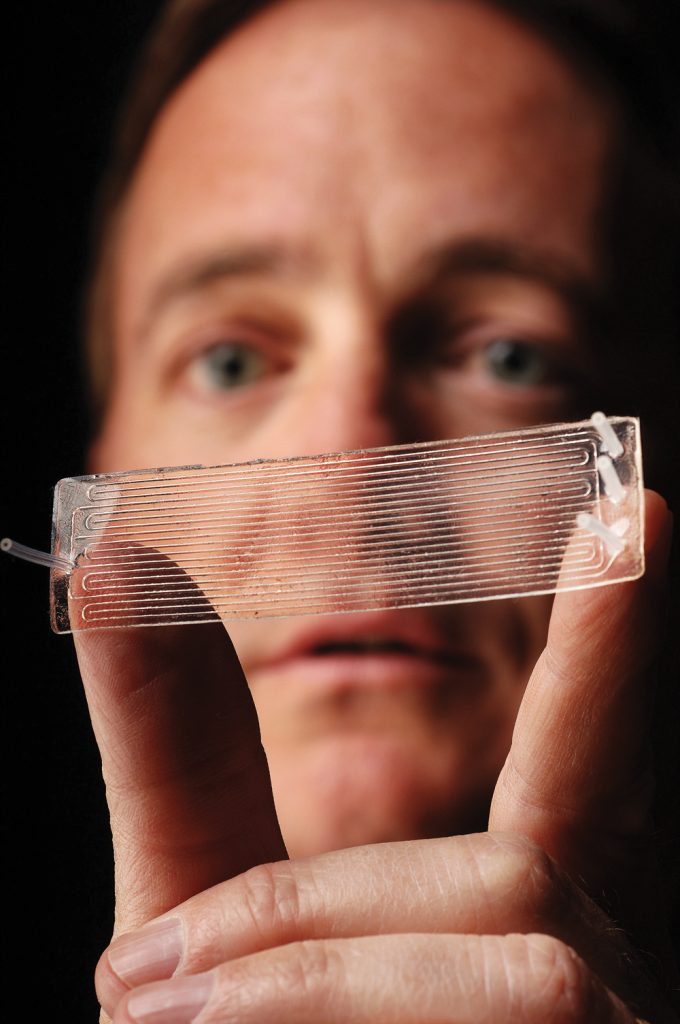

One promising SHM sensor, a Comparative Vacuum Monitoring (CVM) sensor, is a thin, self-adhesive rubber patch, ranging from dime- to credit-card-sized, that detects cracks in the underlying material. The rubber is laser-etched with rows of tiny, interconnected channels or galleries, to which air pressure is applied. Any propagating crack under the sensor breaches the galleries and the resulting change in pressure is monitored.

The sensors — manufactured by Structural Monitoring Systems, Inc. (SMS) — are inexpensive, reliable, durable, and easy to apply, says Roach. More important, they provide equal or better sensitivity than is achievable with conventional inspection methods, he says.

The CVM sensors were tested in a lab and validated on three commercial aircraft beginning in April 2005. Boeing’s inclusion of CVM technology in its Common Methods NDI Manual, an aviation industry first for NDI, is the culmination of a comprehensive, two-year validation program by Sandia in cooperation with the FAA, Boeing, SMS, a number of US airlines, and the University of Arizona. Work on additional applications for Southwest, Northwest, and Delta Airlines is underway.

Sandia also is developing or evaluating a variety of other sensor systems. Technologies being considered include flexible eddy-current arrays, capacitive micromachined ultrasonic transducers, piezoelectric transducers that can interrogate materials over long distances, acoustic emission sensors, embedded fiber optics, nickel strip magnetostrictive sensors, and conducting paint whose resistance changes when cracks form underneath

SHM techniques also could monitor the structural well-being of spacecraft, weapons, rail cars, bridges, oil recovery equipment, buildings, armored vehicles, ships, wind turbines, nuclear power plants, and fuel tanks in hydrogen vehicles, Roach says. Sandia already is applying SHM to a variety of structures.

“There is recognition that SHM’s time has come, an opinion you would not have heard from many people a few years ago,” says Roach.