ALBUQUERQUE, N.M. — The cars go by so fast you can barely see them. Maybe a foot in length, going 200 miles per hour around a 70-ft diameter track, they sound like amplified mosquitoes, or maybe like a dentist’s drill hitting a soft spot on your tooth, backing off, returning, backing off, for the six times it takes to go around a competitive track of ¼ mile.

“I love the sound,” says Ed Baynes, a senior technologist at Sandia National Laboratories. “I grew up with it. It’s by the sound you know when [the vehicle’s] reached its maximum speed. When its fuel mix is just right, that’s when you start timing it.”

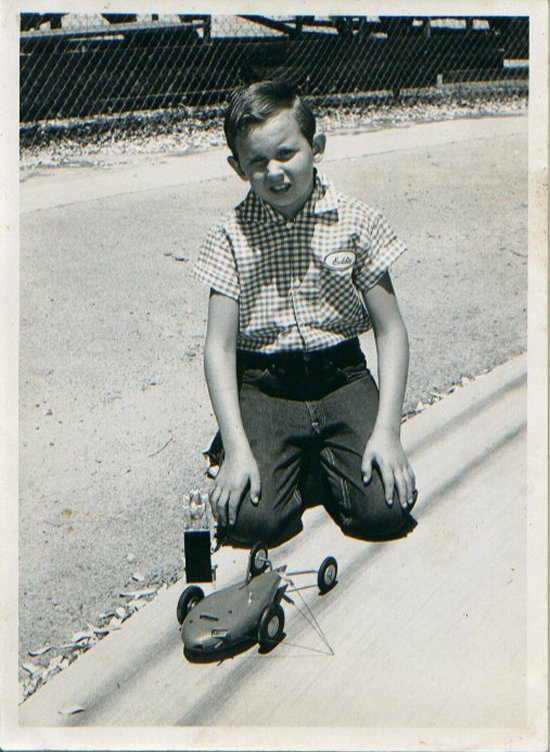

The gas-powered cars, tethered to a central pole buried four feet in the ground, whipped around the track more slowly when Baynes was a boy in Ontario, Calif., about 30 miles east of Los Angeles, in the mid 1950s.

When he worked on tether cars with his dad, they had heavier bodies — cast aluminum frames instead of magnesium, with balsa wood bodies resembling actual automobiles instead of the more streamlined cigar-like shapes of today.

Still, 140 miles per hour was pretty fast in 1955, and Baynes went out with his dad to their garage or to tracks as often as he could.

“I never cared about sports,” says Ed, “but if it had wheels on it, I was interested.”

His dad, Ed Sr., was known nationally in tether car circles as a man who raced and who helped other racers. Seeing a son with an interest in things mechanical, the father had his own method of instruction.

“We bought a used bike for $10,” said Ed. “My dad told me he would paint it if I took the bike apart and put it back together.”

After Baynes disassembled the bike, his dad painted it “a beautiful metallic purple.”

Later, when he was nine, Ed was taking tether cars apart by himself.

He owned his first full-size car at age 14, but it had no transmission.

So Ed’s dad brought home a box of gears and a one-page technical drawing of a tranny.

“There it is,” he told Ed. “If you can put it together.”

Ed remembers, “I sat outside on Memorial Day weekend, listening to the Indianapolis 500 radiocast with all these parts around me. I had it figured out by the end of the day. It was functioning within a week.”

His upbringing made him a believer in hands-on experience: “Developing a concept, taking it into a machine shop, and making it operate is wonderful training.”

In Europe, he says, some engineering programs require students to design, build, and race tether cars. Unlike the US, where the sport now operates only three tracks nationwide,

“Europe maintains a large number of tracks, some even indoors, so they can run cars in bad weather. Russia, Sweden, and Italy are very much into it,” he says.

Ed went on to build hot rods, race cars, and motorcycles.

But his formal education stopped with a two-year college certificate.

“Maybe I never put my goals high enough,” he says. ““I was successful at everything I did.”

There was, though, at least one thing lacking from his technical toolbox: an understanding of marriage. “It’s true you learn some things by example from your parents, but I grew up more skilled in technical work than in my personal life,” he says. “One of most crucial things you do is pick a person to marry. They taught things in school but not how to pick a partner nor how to be a parent. They didn’t provide the tools.”

He left California after one breakup and moved to New Mexico. He was a contractor to Sandia for 17 years before hiring on as a technologist in 1998.

But, just as he figured out mechanical things, he learned to work out relationships. They mature slowly, he found.

Six or seven years ago, he says, he dated a Lovelace doctor who, like himself, had just been through “a miserable divorce.”

While the courtship looked exciting — the pair would ride his motorcycle to balloon fiestas and other locations — they took time to really get to know each other.

Five years ago, he wed the interesting, highly educated woman 18 years his junior whose salary was much higher than his.

“A lot of men might be intimidated by a partner with a better education and higher paying job,” he says, “but I don’t think that’s what a marriage should be based on.”

When his wife got an opportunity to practice in Las Cruces, the couple moved there from Albuquerque and purchased a house that satisfied them. On three acres, there was a horse stable for Ed’s Atlanta-born wife, and a shop for Ed, currently filled with old Harleys that he renovates.

Professionally, Baynes put his diverse technical skills to use in the Southland for Sandia by working on border entry control and contraband detection, and then on a variety of border projects related to energy and water, including supporting the DOE Solar American Cities program.

That’s almost the end of the story. He had rebuilt almost everything around him needing rebuilding.

Except that when Ed’s dad passed away a few years ago, Ed went west to clean out his estate. One of the few possessions he kept were his dad’s balsa wood carving tools from the 1950s. They were the tools used to make the tether car bodies Ed had raced as a boy.

Though he hadn’t worked with tether cars in 40 years, he found himself searching through “want ads” for one.

He removed the topside of one he bought and, using his dad’s tools, carved a new body for it.

“I bought five balsa wood blocks because I figured it would take that many tries to get it right, but it was perfect the first time,” he says factually.

He painted the tether car the same beautiful metallic purple that Ed Sr. had painted Ed Jr.’s bicycle as a boy — the same color as his father’s own tether car, back in the 1950s. As a final touch, Ed gave the car his dad’s racing number, 11.

“The car won first place in its class this fall at the nationals,” he says.

But he got most of his satisfaction from assisting other competitors.

“The nicest compliment I got was from an oldtimer who said, ‘Ed Junior is always helping out. He’s just like his dad,’” Ed says.

He pauses. He had gone a long way to come home.

“You realize later in life,” he says slowly, “there’s a lot of good things our parents give us.”

Download 300dpi 2.5MB JPEG

Download 300dpi 2.5MB JPEG