ALBUQUERQUE, N.M. — Two Sandia National Laboratories research teams, each partnering with private industry, have won R&D 100 Awards in the annual competition for innovative technology sponsored by R&D Magazine, a trade magazine based in the Chicago area.

The Sandia winners invented the Component Analysis Software (Compass), which automatically analyzes the chemistry of a micro- or macrostructure; and the MTR8500 Very Short Reach (VSR) OC-192 Parallel Array Transponder Module, which provides standardized 10-gigabit fiber optic data communications using much lower-cost one-gigabit components by spreading the payload over 12 parallel optical fibers.

The software was submitted by Sandia engineers Paul Kotula and Michael Keenan as a joint entry with Thermo NORAN of Middleton, Wis., and the transponder was submitted by Sandia manager Michael Daily as a joint entry with EMCORE’s Fiber Optics Division of Albuquerque.

Technical experts chosen by R&D Magazine select 100 winners of the annual contest. The winning research must not only be original but also show promise of real-world application. The winners will be honored at a banquet the magazine hosts in October at Chicago’s Navy Pier.

“Each of these awards recognizes innovations that are at the frontiers of science applications,” said Sandia President C. Paul Robinson. “We have focused on atoms-up engineering for several years now, and the Compass software provides essential information to make this a reality. The revolution in faster information transfer is already benefiting many of Sandia’s missions, and the new fiber optic transponder will help advance the information revolution.”

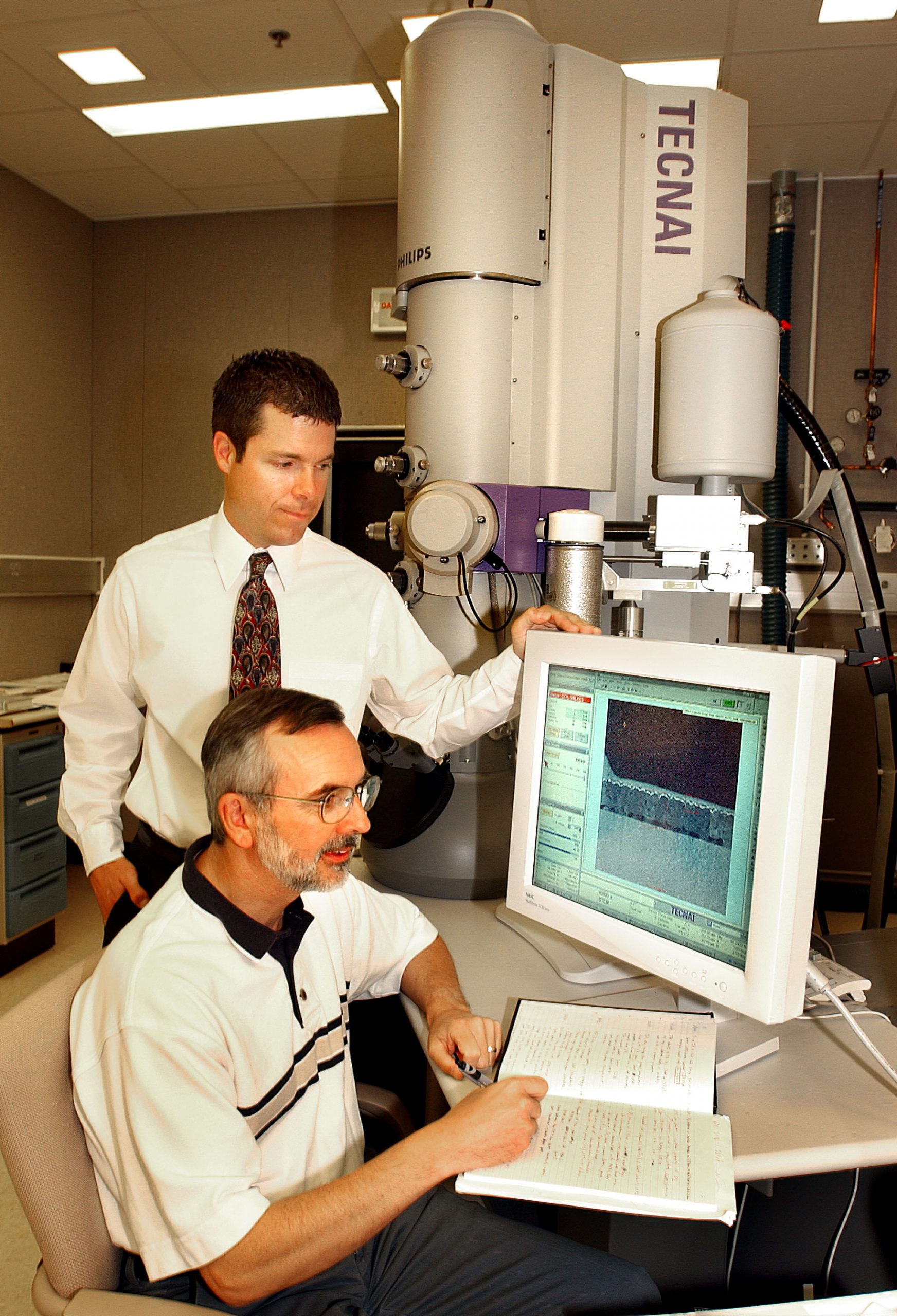

Component Analysis Software (Compass)

Compass was developed to automate chemical analysis of micron to sub-micron microstructural features in the scanning electron microscope (SEM).

“We developed Compass to make microanalysis more objective; to automatically identify and chemically characterize large areas of a microstructure and large numbers of particulates; to comprehensively analyze such things as semiconductors, metals, ceramics, brazes, minerals; and to automate the microanalysis component of failure analysis,” Kotula said.

Compass has many direct applications in the areas of semiconductors, ceramics, metals, welding, brazing, soldering, forensics, failure analysis, atmospheric particulate analysis, and geology. In each of these cases, knowing the chemistry of a specimen is critical to understanding how processing affects microstructure and microchemistry, or for fingerprinting known materials for quantitative comparison to unknowns.

“Compass has made a quantum leap over available products by automating a procedure that is tedious, time consuming, and fraught with artifacts,” Kotula said. “Thousands of particles can be chemically analyzed in minutes.”

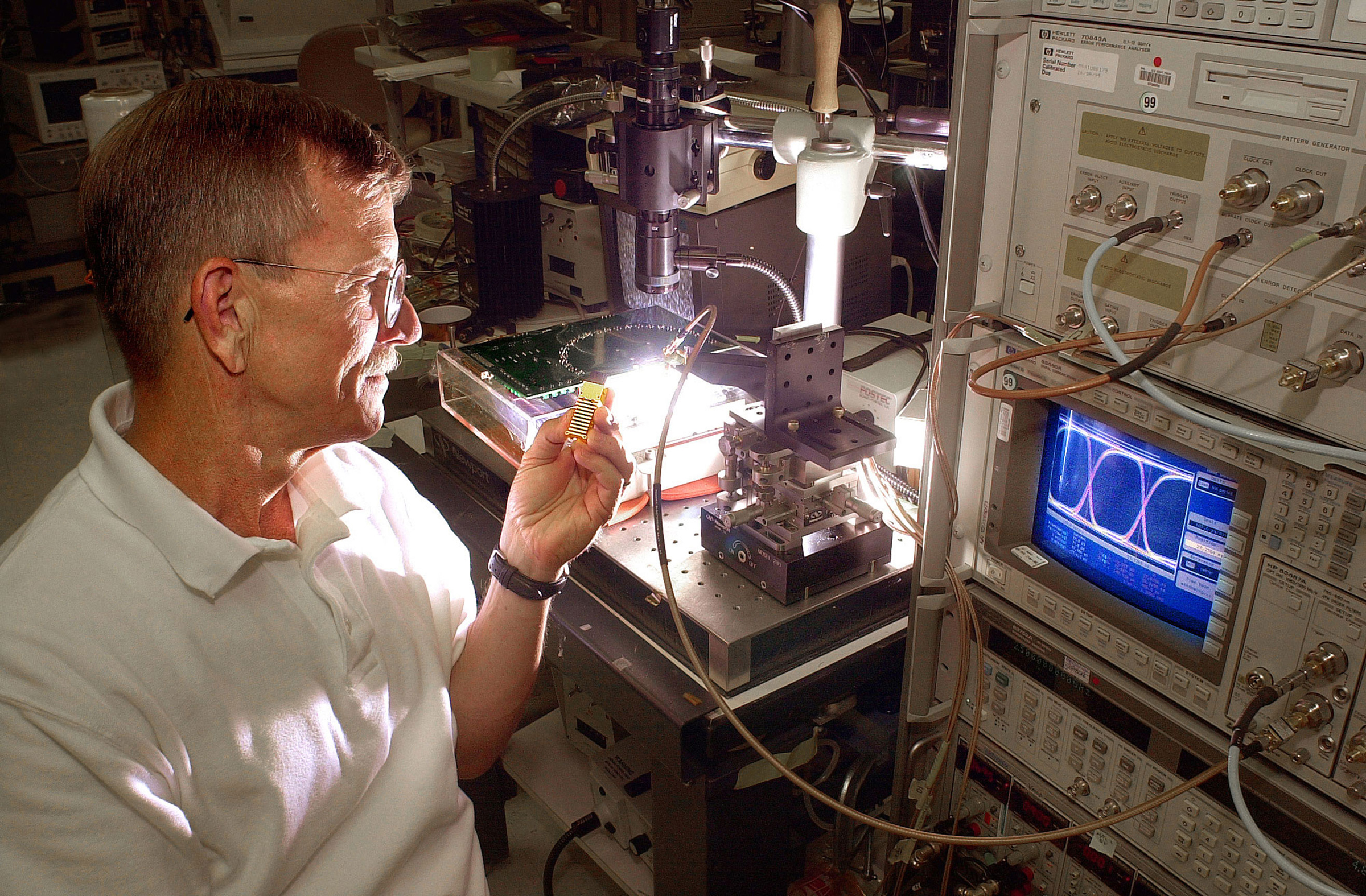

MTR8500 Very Short Reach (VSR) OC-192 Parallel Array Transponder Module

The new, short-reach (less than 300 meters) transponder is expected to reduce costs significantly, potentially by a factor of 10, over transponders currently used in these applications. It also is scalable to higher data-rate systems as needed. Because 75 percent of optical interconnects are in this shorter distance class, costs will be cut dramatically, opening the information age to more and more people in new ways.

“The world has the potential to benefit enormously from being interconnected,” Daily said. “Not only in the ways we see today through computer-to-internet links, but also in the pervasive transparent interconnection of homes, schools, hospitals, businesses — all of society. The key to realizing this dream is the dramatic cost reductions demonstrated by this new invention and enabled by advances in the design and assembly of microsystem technologies.”

Cost of the new system is reduced by trading off interconnect distance for less expensive technologies. Instead of using a single high-quality expensive fiber for serial data transmission, a low-cost 12-parallel channel multimode fiber ribbon cable is used. And instead of using a single, expensive 10-gigabit per-second edge-emitting semiconductor laser, a low-cost, single-chip array of 12 vertical cavity surface emitting lasers (VCSELs) and detectors are used. Because the conversion of signals from electrical-to-optical and optical-to-electrical is occurring at speeds a factor of 10 less than in current products, lower cost optoelectronics and packaging can be used.

The ability to implement these parallel channels in a low-cost way is made possible by proprietary microsystem assembly technologies developed and patented by Sandia and EMCORE Corporation.