Download 300dpi JPEG image, ‘solar.jpg’, 912K (Media are welcome to download/publish this image with related news stories.)

ALBUQUERQUE, N.M. — The Department of Energy’s Sandia National Laboratories will join forces early next year with one or more Native American tribes to test a new solar electricity generating system that will be the power source for a water pump.

The unit will be placed on Indian lands in the Southwest where it will pump water for agricultural purposes and be close enough to home for observation by researchers in Albuquerque.

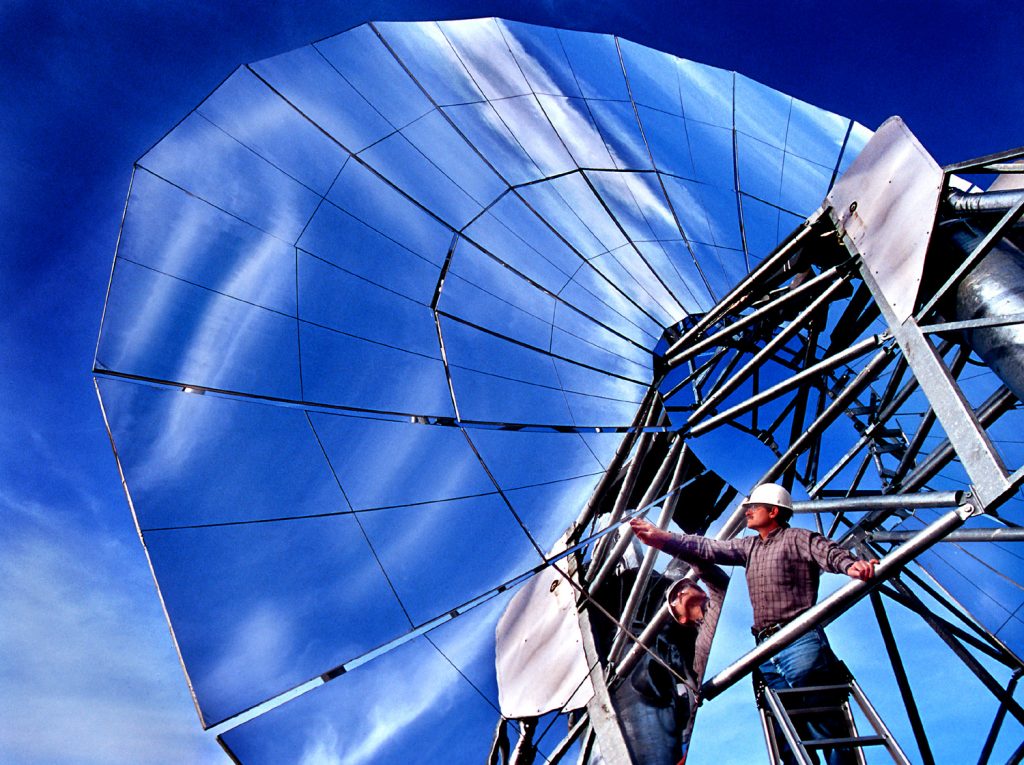

A first prototype of the 10-kW Solar Dish/Stirling Remote Power System, which incorporates the best of advanced solar technology developed at Sandia in recent years, consists of 500 square feet of mirror collector panels and an engine that converts solar energy to electricity. The system has operated for more than 500 hours at Sandia’s National Solar Thermal Test Facility, meeting all its performance objectives for power, efficiency, and automated operation.

A second-generation prototype, planned for this fall, will drive a conventional water pump. The first solar pumping system to be erected on a reservation is anticipated early in 2001.

“This new solar system is designed to provide power in remote areas for such applications as pumping water, operating a mill, or providing power to a remote village,” says Craig Tyner, manager of Sandia’s Solar Thermal Technology Department. “It will be small enough and, at a price of $30,000 to $40,000, affordable enough to be practical.”

He expects the major markets for this system will be international. However, it might also be used in hard-to-reach rural areas in the United States, such as Indian reservations.

Sandia representatives are currently talking to several different tribes in Arizona and New Mexico about installing demonstration systems on their lands. In the next few months Tyner anticipates a working relationship will be established with several Native American partners. Sandia will work closely with the tribes to train operators and maintenance personnel, as well as gain a better understanding of how the system can best serve the people.

The new remote power system is being developed as part of DOE’s Concentrating Solar Power Program, which is providing the funding.

Work on the first prototype started about a year-and-a-half ago. The Sandia-led team put together a working system in 10 months — receiving the go-ahead for the project in October 1998 and producing working hardware by July 1999. Since then the team has been refining the system and preparing to erect a new collector, generator, and water pump system.

The solar power system consists of three parts. One is the power conversion unit, which features a SOLO 161 Stirling engine, an electric generator, and a solar receiver. The Stirling engine, made by Solo Kleinmotoren of Germany, has a proven track record of hundreds of thousands of hours of operation.

Other parts of the system include the solar concentrator, featuring advanced structural mirrors developed at Sandia, and system controls, which provide automated control, fault detection, data acquisition, and communications. WG Associates of Dallas, Tex. designed and built the solar concentrator and provided system controls.

To generate electricity the sun-tracking mirrors concentrate sunlight onto a receiver that sits on top of a platform extended about 18 feet from the mirrors. The receiver collects and transfers the sun’s heat to the engine. Helium fills the sealed-system engine. As the helium is heated and cooled, its pressure rises and falls, causing the engine pistons to move and produce mechanical power. The mechanical power in turn drives a generator and makes electricity.

One aspect of the solar system that makes it appealing for electricity production at remote sites is its ability to operate automatically. Without operator intervention or even on-site presence, it starts up each morning at dawn, operates throughout the day, responding to clouds and wind as needed. Finally it shuts itself down at sunset. The system can be monitored and controlled over the Internet.

“It needs very little intervention,” says Sandia researcher Rich Diver. “It knows where the sun is at all times. It senses sunlight and comes on. And it will automatically shut down if something undesirable happens — like high winds.”

From the ongoing testing, the researchers are already learning about ways to improve the system. They are working on design improvements to reduce structure size and weight, simplify installation, and operate in a stand-alone mode without a grid tie.

Diver says that over the next several years the technology to build the solar power systems will be transferred to industry partners as suppliers. These suppliers will assume responsibility for planning and implementing international manufacturing, marketing, sales, and support efforts.

Previous studies by US industry have estimated markets for this type of remote system to be as much as several billion dollars per year — a great potential for a new system. For the Sandia researchers working on the project, however, the potential market isn’t the only driver for the project.

“The people in the program are really dedicated to making solar power work. They see it as a way to improve the quality of life for people in Third World countries by bringing them clean power. And they think it’s a fun project. They had free rein to put their creative skills to work and they’re doing amazing things,” Tyner says.