Download 150dpi JPEG image, ‘Reel.jpg’, 1MB

Albuquerque, N.M. — Intel Corp. and the Department of Energy (DOE) announced today (Dec. 8) that Intel will provide a no-fee license for its Pentium® processor design to DOE’s Sandia National Laboratories for the development of custom made microprocessors for US space and defense purposes. The agreement saves US taxpayers hundreds of millions of dollars in microprocessor design costs and provides the federal government with a 10-fold increase in processing power over the highest performing existing technology.

In a ceremony attended today at Intel’s Santa Clara, Calif., headquarters by Secretary of Energy Bill Richardson, NASA Administrator Daniel Goldin and others, Intel said it would license the design to Sandia, DOE’s lead lab for microelectronics research and development. Sandia will develop a custom, radiation-hardened version of the Pentium processor for use in satellites, space vehicles, and defense systems. Radiation hardening is required to “immunize” systems and applications from radiation, such as cosmic rays, which affect the reliability of conventional electronics.

“The Pentium processor design will offer tremendous performance, flexibility, and reliability for critical government applications,” said Craig Barrett, Intel President and chief executive officer. “This agreement allows the government to apply the vast research and development activity that Intel has undertaken for the commercial market to its mission-critical needs.”

Secretary of Energy Bill Richardson heralded the agreement as a model of industry and government cooperation. “We’re proud to be a part of this unique opportunity to partner with Intel to significantly advance the state of the art in space and defense electronics,” Richardson said. “This is a precedent-setting show of cooperation, in which the taxpayers are among the biggest winners.”

Sen. Pete Domenici (R-N.M.) said Sandia and Intel both deserve congratulations for developing this latest partnership. “Intel deserves special thanks for allowing the government to benefit from their extensive development work on the Pentium processor,” Domenici said. “Intel’s generosity provides the government with important new capabilities and saves it many millions of dollars. This partnership highlights the tremendous benefits that accrue to the taxpayers, as well as to private industry, when partnerships are used to leverage the resources of each party.”

Download 150dpi JPEG image, ‘rover.jpg’, 544K

“The five generations of chips that Sandia has hardened have been essential elements in earth satellites, the Galileo mission, missiles, nuclear weapons, and in other applications where radiation degrades both the performance and reliability of conventional electronics,” said Sandia Executive Vice President John Crawford. “DOE and Sandia are proud to be partnering with Intel, NASA, the Air Force Research Lab, and the National Reconnaissance Office to produce a rad-hard version of the Pentium. If we had to pay to license the Pentium technology, government costs would go up considerably.”

The Pentium processor is one of the most popular computer chips in the world. Developed by Intel at an estimated cost of more than $1 billion, it can run more software — including applications, development tools, and diagnostic tools — than any other chip ever designed. Intel cofounder Gordon Moore, who also participated in today’s announcement, was instrumental in advancing the current agreement and directed the transfer of the first Intel microprocessor designs to Sandia more than 18 years ago.

In recent years, the rapid pace of design innovation for commercial integrated circuit (IC) applications, such as personal computers, has outdistanced the budgetary ability of military and space designers to design comparable performance ICs for radiation environments.

The licensing agreement highlights a long-standing relationship between Intel and Sandia in the development of advanced technologies. Intel provided similar rights to Sandia in the 1980s for the Intel 8085 and 8051 microcontrollers. Intel also built the world’s first teraflop (one-trillion-operations-per-second) computer — the fastest in the world at the time — for Sandia under government contract in 1995. The supercomputer was based on 9,200 Intel Pentium Pro processors. There have been numerous other cooperative R&D projects over the years. Among the national laboratories, only Sandia has both the design and the microelectronics fabrication infrastructure to attempt a project as complex as redesigning and manufacturing a Pentium-class chip with radiation-hardened characteristics. Sandia combines a detailed understanding of the art and science of manufacturing radiation-hardened chips with a working knowledge of the modern microelectronics industry obtained through numerous partnerships with leading-edge US microelectronics companies.

The Pentium processor redesign effort will involve several government agencies that are expected to use the increased computing power for a variety of applications. DOE, NASA’s Jet Propulsion Laboratory (JPL), the Air Force Research Laboratory (AFRL), and the National Reconnaissance Office (NRO) are the initial agencies with projects identified. Some of the applications will include earth satellites, space probes, missile defense, and other advanced military systems.

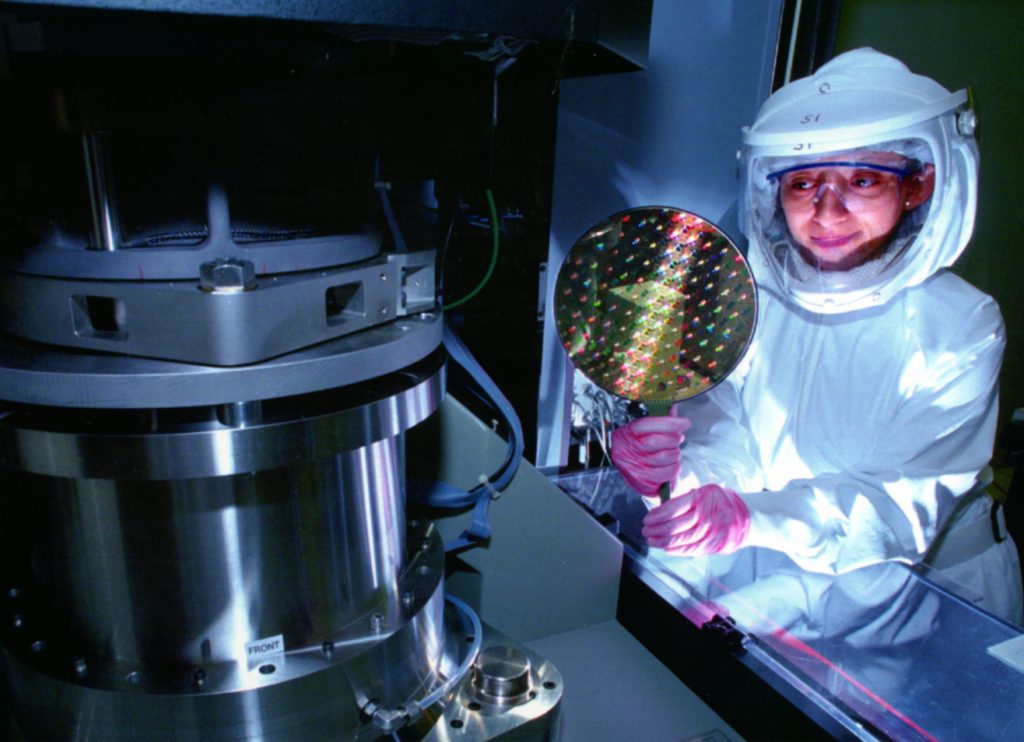

Download 150dpi JPEG image, ‘Carrillo.jpg’, 752K

Prototypes of the custom chips will be fabricated and tested at Sandia’s Microelectronics Development Lab in Albuquerque, N.M. For larger quantities, Sandia will seek the participation of specialty commercial suppliers that traditionally serve the rad-hard IC needs of defense and space-related markets. Manufacturing will occur only in the US, and the products will be subject to strict export controls.

Intel, the world’s largest chipmaker, is also a leading manufacturer of personal computer, networking, and communications products.

Backgrounder

Radiation Hardening of Microelectronics

Microchips — the kind used in everything from personal computers to automobile electronics to breadmaking machines — work fine in their intended environments. But if you try to operate one of these generic microchips in the presence of ionizing radiation, the kind that satellites encounter in outer space, for example, it will no longer function correctly. The ionizing radiation penetrates the protective packaging around the microchip and strikes the transistors in the circuit. This can change the chip’s electrical parameters, adding extra electrical currents that shouldn’t be there and altering the circuit’s operations.

There are ways to counter the effects of ionizing radiation. Circuit engineers can make the chips themselves more resistant to the radiation that penetrates the protective packaging. They do this by changing the designs of the chips and by altering the ways that the chips are manufactured. This extra protection, called radiation hardening, has been called both a science and an art. Many microelectronics experts worldwide have long considered this expertise to be synonymous with the US Department of Energy’s Sandia National Laboratories.

More difficult to design, trickier to manufacture

Radiation-resistant chips are more difficult to design and harder to manufacture than “normal” chips. Some of the — often proprietary — design and manufacturing tricks that speed up off-the-shelf chip operation cause extra performance vulnerabilities in the presence of ionizing radiation. Similarly, some of the shortcuts that allow chip makers to turn out more chips at lower prices introduce chemical weaknesses in the atomic structure of the transistors that are attacked by ionizing radiation. Thus, standard chip-making methods cannot be used to make chips that must survive ionizing radiation. For these reasons, special knowledge must be applied to design and manufacture chips that must survive ionizing radiation.

Sandia engineers generally use two complementary approaches in radiation-hardening microchips. First, they design radiation-hard characteristics into the chip. Then, at the processing phase, they use special techniques that mitigate radiation effects.

Sandia radiation-hardening experts over the years have had to learn the device physics of the transistors and other circuit elements, and how they are affected at the atomic scale by various kinds of radiation. They’ve also learned, through long experience, how fabrication processes — patterning, oxide deposition, ion implantation, and such — affect device sensitivity to different radiation sources.

Thinner layers, lower temperatures

In general, here is how chips are made more resistant to radiation: Very thin layers of oxide are used to form the working and insulating parts of the devices and regions between the transistors. These layers are made as thin as possible without compromising reliability. Reducing these thicknesses decreases the sensitivity of transistors to ionizing radiation because it limits the amount of unwanted charge that can accumulate in those layers to change the operating characteristics of the underlying devices.

There’s a catch, though, a price to be paid. Extremely thin oxide layers increase the importance of precise processing. Any imperfection in one of those layers could ruin the chip by causing an electrical short. After the gate oxide layer is grown onto the substrate, the rad-hard chip makers must ensure that all additional processing steps use temperatures lower than the temperature of the gate oxide growth steps. That’s in the neighborhood of 900 to 1000 degrees C, depending on the type of chip being made, versus the 1100 degrees C that’s available to commercial processes. Using higher temperatures would alter the gate oxide’s atomic structure, compromising radiation resistance. The restriction against higher processing temperatures increases the difficulty of many of the later fabrication steps.

In addition to changing the way the transistors in the circuit are manufactured, other tricks change the way that the transistors are combined to form working circuits. As one example, the interconnections — the tiny wires etched onto the chip — are made larger than would be common for commercial chips. These wider wires can handle radiation-induced currents that are much larger than would be created during normal operation in the absence of radiation. Many years of scientific analysis and trial and error have generated many such guidelines for reducing the radiation vulnerabilities of modern electronics.

Though chip fabrication techniques can be used to increase chip radiation immunity, significant design changes are even more important in making the integrated circuits inherently radiation hard. The challenge is to design rad-hard chips that will continue to perform reliably and efficiently in spite of ionizing radiation exposure.

A unique relationship: Intel and Sandia National Labs

Intel is making the design of the Pentium, the world’s most popular microprocessor, available for US space and defense systems in a unique partnership with DOE’s Sandia National Laboratories. Among the national laboratories, only Sandia has both the design and the microelectronics fabrication infrastructure to attempt a project as complex as redesigning and remanufacturing a Pentium-class chip with radiation-hardened characteristics.

Intel trusts Sandia with the key design aspects of its highest-value commercial product, in part because Sandia has shown that it can protect Intel’s intellectual property during previous microprocessor design transfer partnerships.

Sandia combines a detailed understanding of the art and science of manufacturing radiation-hardened chips with a working knowledge of the modern microelectronics industry obtained through numerous partnerships with leading-edge US microelectronics companies.

Intel has the highest confidence that Sandia can protect Intel’s design — the company has an investment of more than $2 billion in the Pentium design — and develop a radiation-hardened version for manufacturing by third-party vendors. These vendors will get a manufacturing recipe that enables them to build the Pentium but not reverse-engineer the key design tricks.

Third design transfer in 18 years

The transfer of the Pentium design represents the third chip design transferred from Intel to Sandia over the last 18 years, and is part of a long-term cooperative relationship. The specifics of this transfer have been under discussion for almost two years.

Prototypes of the custom chips will be fabricated and tested in small volumes at Sandia’s Albuquerque, N.M., Microelectronics Development Laboratory. For production of larger quantities, Sandia will actively seek, through an announcement in the federal Commerce Business Daily, the participation of specialty commercial suppliers that traditionally serve the rad-hard integrated circuit needs of defense or space-related markets. Suppliers who choose to participate in manufacturing the rad-hard Pentium for government use will receive masks and manufacturing instructions at no cost.

Manufacturing will occur only in the United States, and the products will be subject to strict US export controls.

Sandia and Intel have worked together on a number of mutually beneficial projects over a period of years. These include large projects like the one announced on Dec. 8 — radiation hardening of the Pentium chip — and massively parallel computer development, as well as about 60 smaller projects over the years. Of special interest have been 20 “rapid response” projects in which difficult emergency situations demanded immediate attention. Intel has shared improvements that have resulted from work in contamination control, environmental safety and health techniques with the other companies in the semiconductor industry without charge. Likewise, Intel is licensing the transfer of the Pentium design to Sandia for space and military applications for no fee.

Media contacts:

Intel: Bill Calder, bill.calder@intel.com, (503) 264-5669

DOE: Ram Uppuluri, ram.uppuluri@hq.doe.gov, (202) 586-4940

Technical contact:

Sandia: Robert Blewer, blewerr@sandia.gov, (505) 844-6125