Download 300dpi JPEG image, ‘MEMS.jpg’, 18M (Media are welcome to download/publish this image with related news stories.)

ALBUQUERQUE, N.M.– Micromirrors being developed by the Department of Energy’s Sandia National Laboratories may one day be part of the Next Generation Space Telescope (NGST), the successor to the Hubble that will peruse the universe looking for remnants from the period in which the first stars and galaxies formed.

“We are designing mirrors that will be very, very small, move independently and be able to withstand the very cold temperatures and extreme conditions of space,” says Ernie Garcia, the Sandia engineer leading the mirror development effort.

The mirrors, each slightly larger than a cross section of a human hair, will be sensitive to infrared radiation and, as a result, will be able to detect faint signals from the first billion years after the Big Bang. This will help scientists better understand the origins of the universe.

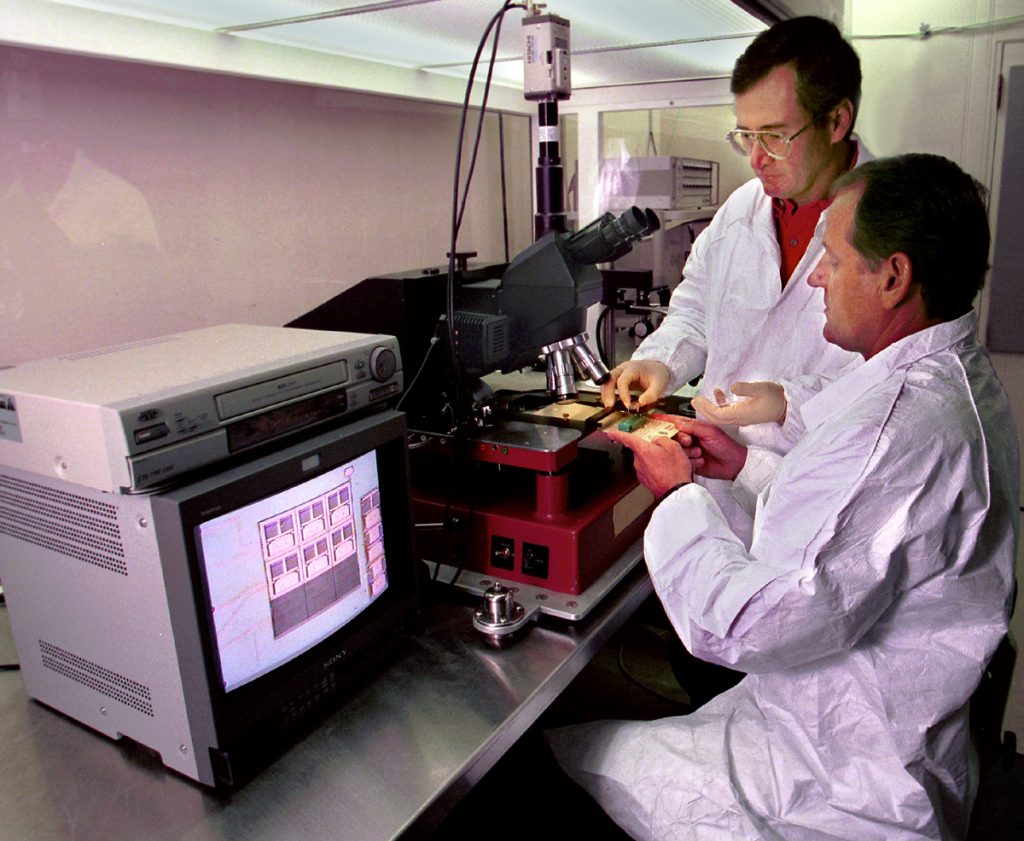

Aware of Sandia’s advancements in microelectromechanical systems (MEMS) technology, NASA approached the Labs last year about developing prototype MEMS mirrors that could be part of the NGST, tentatively scheduled for launch in 2008. The one-year contract began in January, and nine months later Garcia had functioning mirrors to show the agency.

The fast turnaround at Sandia’s Microelectronics Development Laboratory (MDL), which fabricated the mirrors, made it possible for Garcia to provide NASA with a working device quickly.

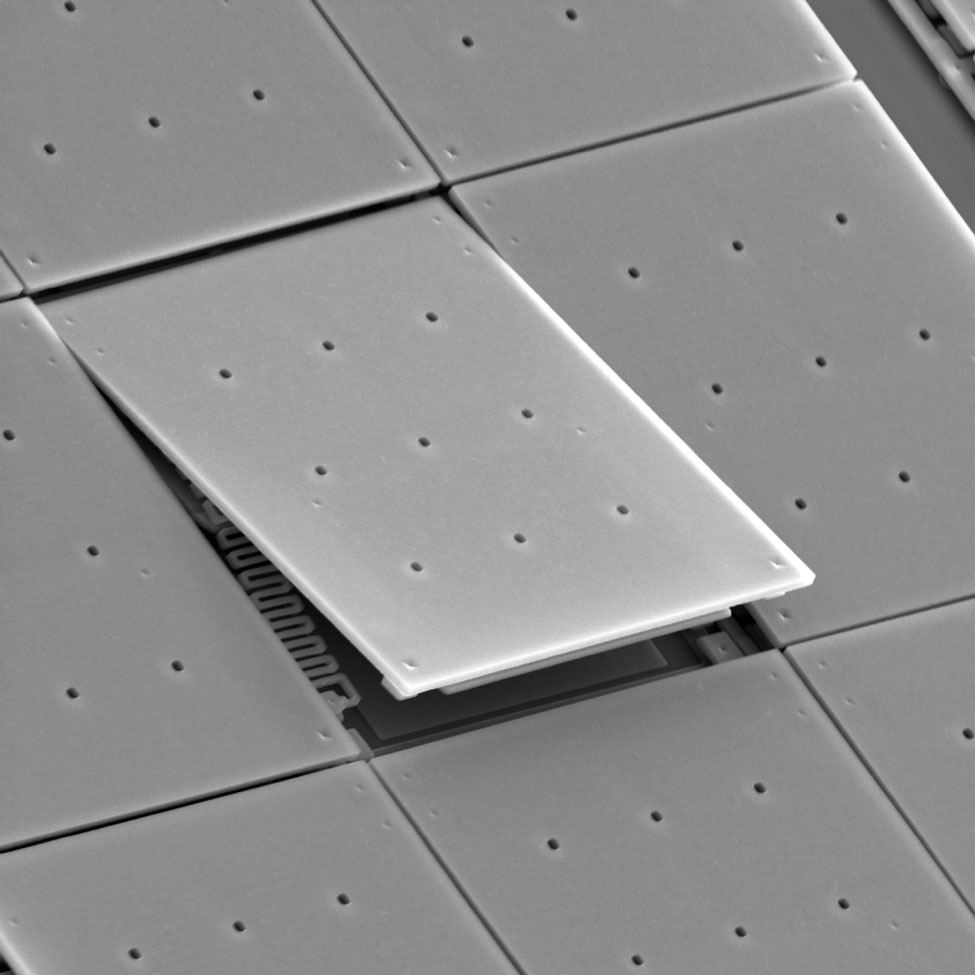

In September Garcia demonstrated to NASA/Goddard Space Flight Center in Greenbelt, Md., an array of working mirrors, each 100 microns by 100 microns with 1-micron gaps between adjacent mirrors, lined up in rows of three. Each row tilted 10 degrees in unison — a large angle for this design. (One hundred microns is slightly larger than the diameter of a human hair.)

“Getting these miniaturized mirrors to rotate to such a large angle was a real milestone in the research,” Garcia says. “It’s something that NASA wanted, and we did it.”

The goal is to have four million of these independently moving mirrors in the NGST. Each mirror could be tilted in different directions to redirect optical signals to an infrared detector.

In light of the success of getting the mirrors to rotate at large angles, Garcia is hopeful that NASA will extend the contract to continue the research.

NASA is pursuing the NGST as the successor to the Hubble Space Telescope in an effort to observe the “Dark Zone,” a period 100 million to one billion years after the Big Bang when primordial seeds began to evolve into the galaxies and stars known today. It would also see formations in the present day universe. The Hubble has provided data about more recent formations, but has been unable to detect the earlier stars that fall in the infrared range because it was designed as an optical telescope.

The NGST, on the other hand, will be extremely sensitive to infrared radiation, and with its large light-gathering mirror and superb resolution, will be capable of detecting the earlier signals. The new telescope will be placed in orbit well beyond the Earth’s moon to reduce stray light and achieve the cold temperatures needed to observe in the infrared.

Currently three entities — Lockheed Martin, Goddard Space Flight Center, and TRW — are studying different design approaches for the NGST. Each approach includes adjustable thin mirrors, deep space orbits, fast-steering mirrors for fine guidance, and infrequent contact with the ground. They differ in the areas of mirror construction, materials and deployment, detector types, sunshield types, vibration control and launch vehicles. Eventually NASA will select one design from the three for the final NGST.

The mirrors Garcia is designing could go into any one of the three NGST approaches as part of the Integrated Science Instrument Module that will also include cameras, spectrographs, and infrared detectors.

Download 300dpi JPEG image, ‘mirror1.jpg’, 119K (Media are welcome to download/publish this image with related news stories.)

The micromirrors will work in conjunction with a very large mirror — possibly eight meters in diameter — that will collect light from a broad area in space. When an object is encountered that appears interesting, the smaller micromirrors would be tilted to reflect the image from only that area, beaming the information to an infrared detector.

Garcia says he still faces several challenges in developing moving mirrors for the NGST.

One is making the mirrors able to function in extremely cold temperatures.

“Instrument operating temperatures in space can be 30 degrees K [-405 degrees F] or lower,” Garcia says. “That means we have to build these mirrors a special way so that they won’t break at such extremes.”

The mirrors are built by depositing thin films of polycrystalline silicon on a silicon wafer. The first layer, called poly0, contains connection wires. The others, poly1, poly2, and poly3, are mechanical layers that allow the MEMS device to move. Garcia plans to soon add on top of the poly3 a final thin layer of gold to reflect infrared light.

Therein lies the problem in cold temperatures, Garcia says.

“Different materials shrink at different rates when subjected to temperature changes,” Garcia says. “As the temperature is reduced, the gold layer will shrink faster than the polysilicon. This will cause stress. If the stress levels get too high, the mirror could break or deform or the gold could peel away. We have to come up with the smallest thickness of gold so that it doesn’t cause excessive stress, but yet be thick enough to reflect the infrareds.”

The MDL will soon begin fabricating an improved mirror design, which will be cold-tested by NASA next year in a cryogenic chamber where the conditions of deep space will be simulated.

Another challenge Garcia is concurrently striving to resolve is that of making each of the mirrors move independently. The new design, which will soon be fabricated at the MDL, has each row tilting in unison and one mirror in the middle tilting and moving independently. But doing this for each of the four million mirrors is a major hurdle.

Find out more about the Next Generation Space Telescope at the Web site, http://ngst.gsfc.nasa.gov.