Download 150dpi JPEG image, ‘MicroPea.jpg’, 1.1MB

LIVERMORE, Calif. — Extending our senses beyond their current limits, bits of hardware may one day discern the faint but informative presence of trace chemicals while mounted on bands of small vehicles that cooperatively canvass the countryside.

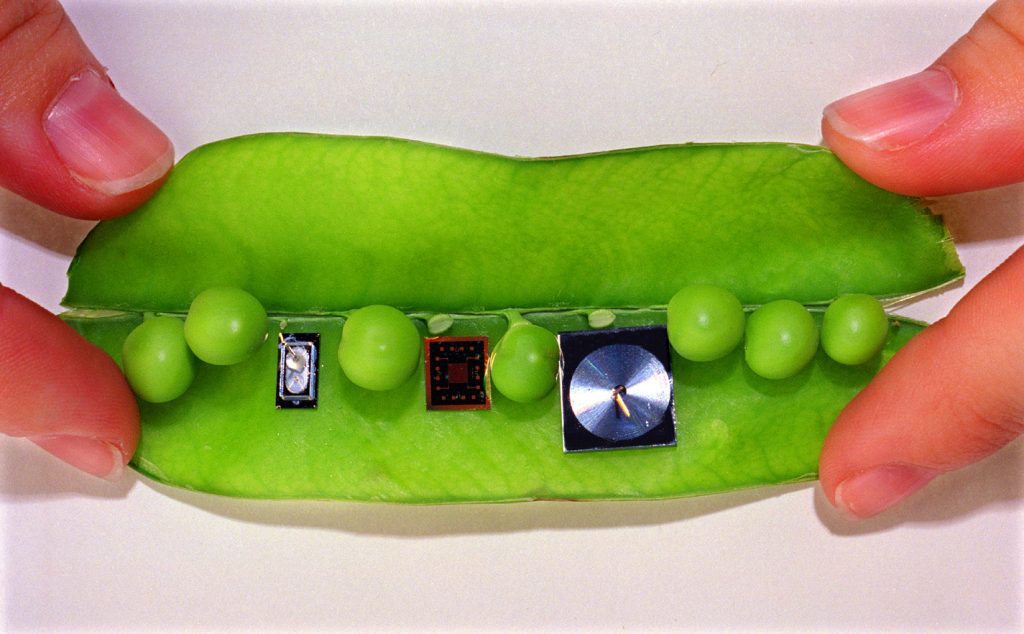

About 40 scientists and engineers at Sandia have been researching how to create such chemical sensors for the last year in the largest project of its type funded by the Department of Energy. At the end of three years, they hope to demonstrate a device about the size of a palm-top computer that can sniff explosives and chemical warfare agents. In five to 10 years, future devices should be able to simultaneously identify hundreds of liquids and gases.

Arrays of these chemistry-labs-on-a-chip could be sent into battlefields or mounted near factories to provide chemical reconnaissance. The same technology might also provide diagnostic screening in about a minute at a patient’s bedside.

“There’s a huge amount of information in chemical signatures which the world is not making use of,” says Sandia chemist David Rakestraw, “because it’s too costly. It’s also very difficult to extract out all of this information using traditional analytical chemistry in a laboratory.”

Shrinking chemical analysis and integrating mass-fabricated chips, as these researchers are attempting, could overcome the cost-effectiveness hurdle. Gains would not only include creating devices that are inexpensive and portable; but speed and reliability would also increase. Sensitivity and selectivity could also be improved through using multiple parallel separations channels that are only practical in microfabricated devices.

Research to create an autonomous micro-chemistry lab involves exploring science in a micro-domain where properties can run counter to normal intuition. For instance, liquids experience no turbulence as they move along channels smaller than a hair, because viscosity dominates. Liquids can thus be pumped by delivering an electronic “nudge” along glass microcapillaries. There, the slight charge of the walls causes opposite charges in the solution to line up facing the walls. Applying a voltage that induces a current causes the liquid to travel along en masse. Sharp separations occur because the leading edge of the liquid does not blur as it would if the liquid was moved by pressure. Compounds in the solution can be shuttled through microchannels in discrete batches.

With this separation technique, an unknown sample could be “parallel processed” in multiple channels that contain beads or microfabricated posts to increase surface area. Subjecting the sample to different solvents and particle coatings would alter the retention time for different components, thus creating a signature “fingerprint” for compounds of interest.

Gas detection would work differently. First, a sample would be gathered on a microporous film, then heated to vaporize. The tiny pulse of gas would then flow into a long, coiled column for separation. From there, separated gases would flow over an array of coated acoustic wave sensors. Different absorptions by the different coatings (signaled by a shift in frequency) would build up a fingerprint characteristic of each chemical. A bonus of this design is that surface acoustic wave sensors’ sensitivity increases as their size shrinks.

The sensors may eventually use novel pumps and valves that take advantage of phenomena such as surface tension that become more dominant in the micro-domain. “The best designs for microfabricated components will take advantage of the fact that interactions are driven by surface behavior,” said Terry Michalske, who oversees some of the research.

Microfabrication and packaging “lab on a chip” components are carried out at Sandia’s Compound Semiconductor Research Laboratory, whose clean-room can make prototype parts in gallium arsenide, silicon, quartz, or glass.

Besides creating sensors, researchers are creating cooperative, distributed sensing and behavior. Sensors in fixed spots or on swarms of small vehicles, known as robugs, could communicate and map the location and movement of suspicious or threatening chemicals.

In three years, Barry Spletzer hopes to have an architecture for what a distributed intelligence system should look like. Nearly two years ago, his group developed its first so-called “small, smart machine”. Built of inexpensive parts and measuring only 1 cubic inch, it drew power from a pair of camera batteries to follow an electrified wire around a tabletop.

They are now working on smarter and more mobile vehicles, simulating their behavior with computer modeling. The final goal is to show that a cooperative swarm using autonomous micro-chemistry labs can quickly locate chemical sources.

Spletzer envisions expendable robugs performing humanitarian demining by moving through fields, powered by lightweight, low-power photovoltaic units. Also, autonomous units able to sniff chemical warfare agents could replace sensors now mounted on jeeps.

Inexpensive mass-fabrication, based on existing microchip manufacture techniques, could spur widespread use of micro-chem labs. Potential national security applications range from detecting weapons of mass destruction to monitoring the state of the nuclear stockpile. Everyday items employing similar technology might also become available one day at neighborhood stores like Wal-Mart, to test water and food or perhaps monitor the course of an illness or determine the safety of the immediate environment.