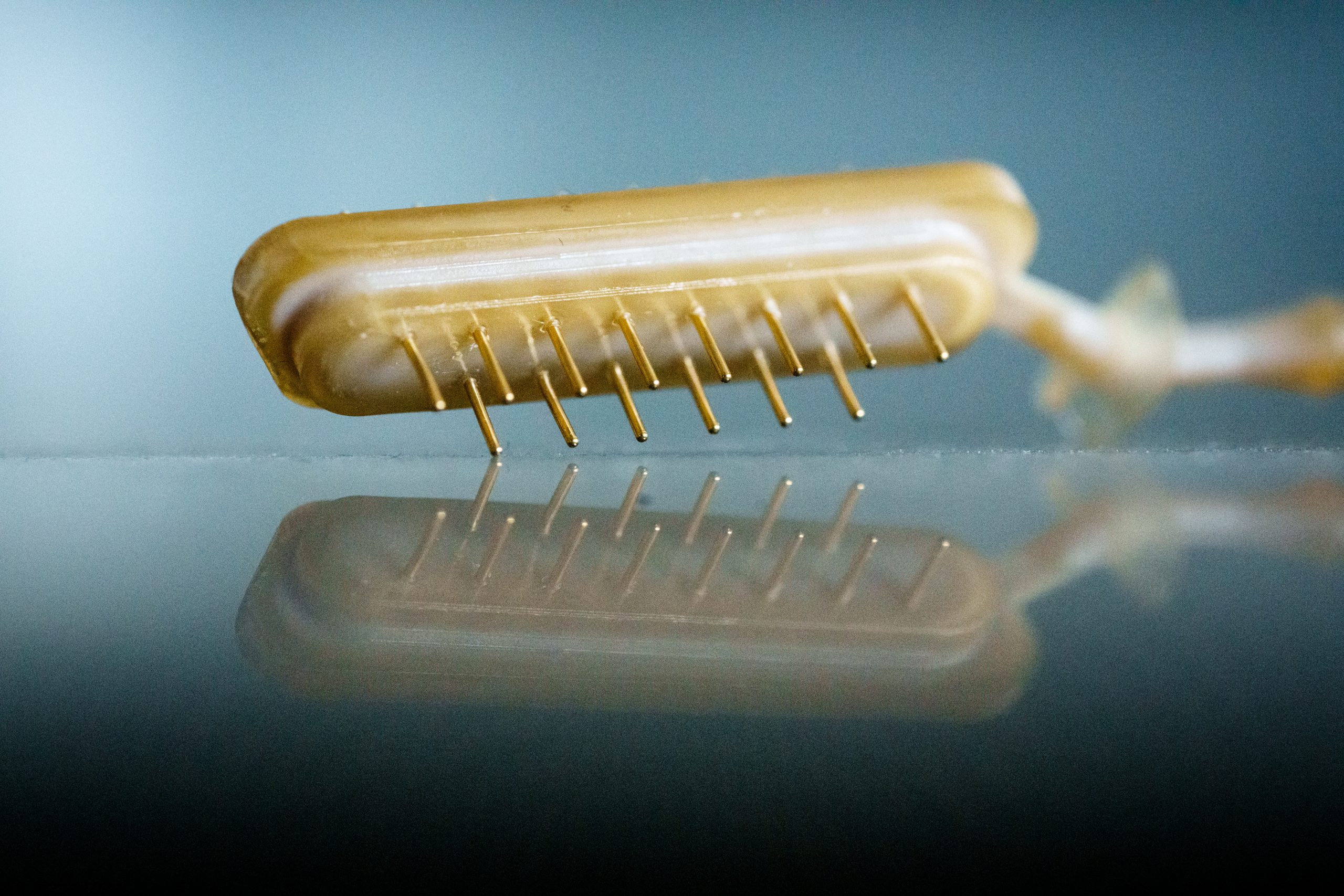

ALBUQUERQUE, N.M. — A group at Sandia National Laboratories is transforming how it develops custom electronic connectors for weapons systems. The Rapid Development Connectors program is a five-year National Nuclear Security Administration-funded project to build a team and lab space capable of fabricating and delivering functional connectors in less than four weeks.

The program’s overall goal is to quickly provide production-representative development hardware to customers while working in parallel with commercial suppliers. Currently, obtaining custom hardware from external companies can take a year or longer. By delivering development hardware sooner, the program accelerates cycles of learning and reduces overall program risks.

Launched in October 2022, the program quickly generated interest from customers.

“We’re really excited for the potential impact this project can have,” said Michael Gallegos, the program’s lead mechanical engineer specializing in connectors and lightning arrestor connectors. “We’re constantly expanding our capabilities and the types of work we can take on.”

Tapping into internal expertise

Sandia’s rapid development connector team is a diverse group of engineers, material scientists, chemists and product designers from multiple centers across the Labs, enabling them to respond to a wide variety of challenges.

“With this lab, we’re expanding our ability to answer a variety of customer requests and calls,” Gallegos said. “It’s a cross-center collaboration, bridging the nuclear deterrence design and materials sciences worlds. Each project gives us an opportunity to innovate and create functional prototypes using our tools and materials in new ways.”

Along with rapid development comes an opportunity for fundamental research in materials and processes essential for producing electrical interconnects. This understanding of materials science helps identify alternatives that meet performance requirements while being quickly manufacturable.

Expanding space

An advantage to the team is the location of the lab space at the Advanced Materials Laboratory on the University of New Mexico campus outside of Kirtland Air Force Base, making it easier to collaborate with industry partners and universities. Over the past year and a half, the lab space has undergone renovations and been equipped with additive and subtractive manufacturing tools and other machines to fabricate electrical interconnects.

Make it fast, learn fast

Co-locating various manufacturing techniques in the lab has sparked innovative ideas, including combining 3D-printing technology with injection molding for low-volume production of parts. Using additively manufactured molds for injection molding, instead of traditional machined metal molds, enables quick turnaround connector manufacturing with more design iterations.

Other ideas coming out of the lab include hermetic seals made with additive manufactured glass and a green alternative for materials used in lightning arrestor connectors. Gallegos is hopeful the lab space will continue to lead to innovative ideas to reduce lead times.

“We want to provide design engineers the opportunity to test new ideas and think creatively without waiting months for hardware,” Gallegos said. “Our goal is to offer as many cycles of learning for product realization teams as possible.”

Customer feedback

Gabriel Arechederra, who is working on the W93 weapons program, emphasized the Rapid Development Connectors program’s role in producing custom electronic connectors in a short timeframe to reduce schedule risk for programs.

“Working with the Rapid Development Connectors program shortens learning and development cycles, and it is positively impacting our development schedules,” Arechederra said. “Based on requirements, we can tell Michael and his group what we want. He can then provide development parts to us in just days or weeks.”

Having hardware quickly in-hand can help design engineers determine if what they requested is going to work.

“When we have parts readily available, we can better understand features and dimensions, and make design changes quicker to make the best long-term design decision,” Arechederra said. “Having this in-house expertise and capability is extremely valuable to our weapon programs.”

Positive impact

Gallegos said the program’s goal is to provide customers with connectors that are the same or nearly the same as what a supplier would produce and ensure that they are going to function as intended.

“We want to provide the best engineering solution by offering designs to suppliers that we’ve vetted and tested internally,” said Gallegos. “There’s a lot of excitement when people hear about what we do. This project has a lot of potential and we’re eager for the future.”

Jared Dove, Michael’s manager, attested to the program’s positive impact.

“Our customers are seeing the value,” Dove said. “The results are self-evident, and the program is seeing a spike in requests.”

The program’s success has prompted plans to incorporate it into the budget for new weapons programs once the current NNSA funding ends.