ALBUQUERQUE, N.M. — Every over-the-counter medication bottle sports a protective seal, usually a plastic wrap or foam layer, or both. These seals offer signs of tampering attempts. In a parallel concern, the International Atomic Energy Agency relies on tamper-indicating devices to make sure it knows if containers of nuclear material have been opened or tampered with.

However, just as a medication bottle might be opened and the tamper seals carefully reattached by a bad guy, the IAEA is concerned its devices could be bypassed and repaired or counterfeited. A possible solution? Engineers at Sandia National Laboratories have developed a groundbreaking prototype using “bruising” materials. Their innovation doesn’t just detect tampering; the new device boldly displays the evidence, like battle scars.

“Our first idea was to create a ‘bleeding’ material where it was extremely obvious that it had been tampered with,” said Heidi Smartt, a Sandia electrical engineer and project lead. “Then we made a new device using these materials where the damage is obvious for people to see. No one has ever done this sort of concept for international nuclear safeguards before.”

Color-changing chemical

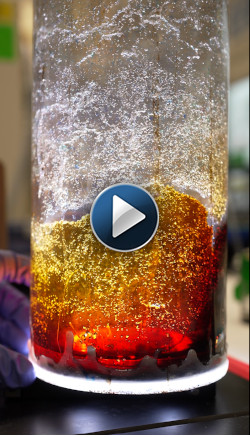

Using commercially available colored water beads, a color-changing chemical reaction and 3D-printed cases, the team made puck-shaped devices that turn dark brown when damaged or the wire loop threaded through them is pulled out.

The important part of the color-changing solution is a chemical called L-DOPA, which the body uses to make several vital neurotransmitters. This chemical can react with oxygen to make melanin, the brown chemical that gives human skin, hair and eyes their color.

The research team explored several other color-changing solutions before determining that the melanin-producing reaction, somewhat like the reaction caused by tanning, was the most practical, said Cody Corbin, a Sandia materials chemist. “This has worked beautifully ever since.”

If someone drills a little hole in the device or attempts to pull out the embedded wires, oxygen leaks in. Once inside, the oxygen reacts with the color-changing solution near the damage, turning it brown. Over time, more oxygen gets in, and the “bruise” grows.

Producing speckled pucks

The Sandia prototype devices are about the size of a stack of seven U.S. half dollar coins, the same size as the metal cup seals the agency has used since the 1960s. The IAEA relies on tamper-indicating devices looped around the openings of cabinets containing vital monitoring equipment. The devices also go on the openings of containers of spent nuclear fuel to make possible diversion obvious.

However, IAEA inspectors need to examine these devices and their wire loops carefully, looking and feeling for odd marks, color differences and other evidence of tampering. This inspection is time consuming and subject to human error. The purpose of the Sandia prototype is to reduce the time and subjectivity of such inspections.

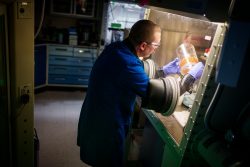

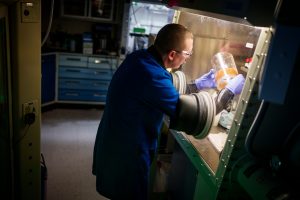

To make the filling for the prototype devices, Corbin’s team adds a little bit of water to a mixture of clear and colored water beads until they are squishy, he said. Then they blend the beads until they are small bits but not a fine powder. Once dry, they transfer the bits into a piece of laboratory equipment called a glovebox.

The glovebox has several pairs of thick rubber gloves that allow researchers to perform experiments in an oxygen-free environment. Once inside the glovebox, the bead bits are soaked in the color-changing solution and then a researcher pours the mixture into 3D-printed cases and seals them. Once sealed, the cases can be removed.

“The other side of tamper-indication is making sure that you have unique identification to ensure that the devices are not easy to counterfeit and replace,” Corbin said. “The bead bit colors provide that anti-counterfeit aspect. If someone wanted to replicate a puck, they would have to get every single red, blue and green speckle in the same spot.”

Putting the devices to the test

The team now is testing dozens of pucks under numerous different conditions that mimic various environments they could be used in, Smartt said. This includes testing them at temperatures ranging from -22 degrees to 150 degrees Fahrenheit, and under intense UV light to age the materials faster, up to the equivalent of three years.

Last year, the team filed a patent on the color-changing material and recently filed a patent continuation on the tamper-indicating device itself. The team may also pursue additional federal funding to test the devices in the field and may seek out corporate partners to license and commercialize the technology. The team has also made entire tamper-indicating enclosures out of the color-changing material as part of another ongoing project.

“From the beginning of our work on these materials, we’ve seen this as really valuable for any industry that’s concerned with the tampering of their packaging,” Smartt said. “I think we can really add value in that visually obvious aspect of our devices; that’s a totally new thing. There are a lot of other possible uses for these loop seals too.”

The bruising materials research was funded by Sandia’s Laboratory Directed Research and Development program. Further development and device prototyping were funded by the National Nuclear Security Administration’s Office of Defense Nuclear Nonproliferation.