ALBUQUERQUE, N.M. — Robert Petterborg saw an opportunity to improve a critical part used to test a weapons system. Using his spare time at work and with the help of his Sandia National Laboratories colleagues, he designed a new cable connector that eliminates misalignments that could interfere with testing and potentially damage hardware.

“I wasn’t assigned this work,” said Petterborg, who is a systems engineer and oversees several product realization teams for deterrence systems. “This was a multifaceted and multidisciplinary project that I voluntarily took on to address a problem. If everyone did things the way we’ve always done them, we wouldn’t have innovation. We would never have anything better than what we have now.”

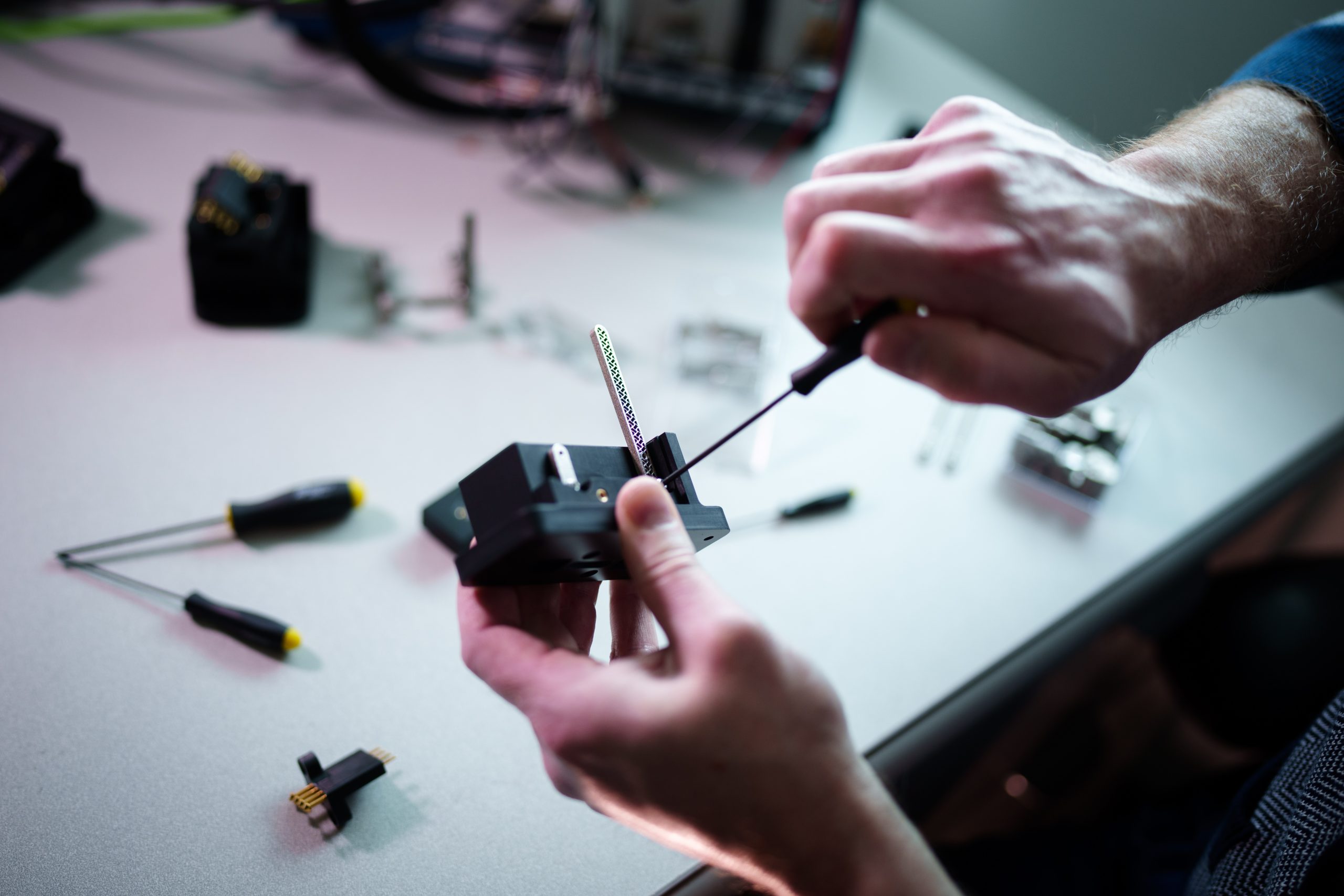

Using 3D printing, or additive manufacturing, Petterborg designed a cable connector used to test the W80-4.

“My role is not to be a design engineer,” said Petterborg, who has previous design experience with test systems, lithium batteries and solar and renewable energy. “This was unorthodox and a risk to do something out of the norm. I knew I had the capability, and Sandia has the diverse resources to make it happen. I took the risk knowing it had a high likelihood of success.”

With the support of his management and the help and input of many others at Sandia, he designed the new connector in about a year and a half. Without using 3D printing and model-based design, Petterborg estimates it could have taken a dedicated team three to five years to develop the connector.

“This new connector will eliminate bad connections, which means a reduction in the number of retests performed at Pantex (Plant),” Petterborg said. “Having a good electrical connection means high reliability and higher confidence in our stockpile.”

Gathering user input

In addition to preventing poor connections, the new connector reduces the chance of potentially damaging cables and their assemblies. Cables are difficult and costly to manufacture.

“We’re very careful with how we handle cables and how they get assembled into products,” said Michelle Pang, a human factors engineer who worked with Petterborg on the newly designed connector.

Pang talked to engineers and operators who use the original connector and gathered information about what made it challenging to use. She then shared prototypes of the new connector.

“They provided a lot of positive feedback that contributed to how we got to this final component,” Pang said.

More user-friendly connector

The newly designed connector has a transparent window at the top, an opening on the side to slide in the cable and a single lever that moves the parts of the connector.

“The window allows the user to visually align the cable in the adapter and then make a reliable repeatable connection by lowering the lever,” Petterborg said. “The lever has hard stops that prevent the user from lowering it too far or pushing it back too high. When considering things that could impact how we build and test our stockpile, simplicity and reliability are paramount.”

The previous connector had many individual pieces, creating a risk of either a poor connection or damaging the cable.

“Instead of having multiple pieces that need to be assembled in the correct order, you’re now working with just one unit,” Pang said. “It takes that guesswork out of whether you have a good connection and eases testing.”

The production technicians at Pantex, where weapons systems are assembled, have also tested the newly designed connector. Petterborg said they provided positive feedback about how easy it is to use.

Rapid fabrication

To make the connector, Petterborg turned to many other groups, including Sandia’s Rapid Development Connector team led out of Connectors and Lightning Arrestor Connectors, in collaboration with Material, Physical and Chemical Sciences and the Advanced Materials Laboratory.

The Rapid Development Connector team tested a variety of materials for the connector and rapidly fabricated multiple design iterations, saving time and money.

“Our team worked through multiple designs with Petterborg and we were able to turn around parts for testing in weeks, sometimes even days,” said Michael Gallegos, the staff member leading the Rapid Development Connector project at the Advanced Materials Lab. “Having a direct line of communication with the people involved in operating the tools and assembling the parts helps provide the best engineering solution.”

Without the Advanced Materials Lab, Petterborg would have sent his designs to an outside manufacturer to be produced, taking anywhere from three to six months for each iteration of prototyping.

“Use of additive manufacturing for both the prototyping and production allowed me to fail and iterate quickly and improve on previous designs, often in less than a week,” Petterborg said. “Failing is a natural part of the design process. Failing quickly, learning and improving on the previous failures faster means a better end result. I was able to narrow in on the most successful paths and then refine the results to meet the requirements in a shortened timeframe.”

Tapping into Sandia’s knowledge base

Petterborg acknowledged he could not have accomplished designing the new connectors without the help of his colleagues.

“At Sandia, we have one of the greatest, deepest knowledge bases of any place in the world,” he said.

Petterborg called on the expertise of machinists across the Labs. He said the input he received from colleagues helped him optimize the design of the connector.

“Working with the various groups at Sandia, I’ve only encountered people who are excited to help and be involved,” Petterborg said. “It’s as much fun for them as it is to me.”

The team’s accomplishment has been getting a lot of attention. Deputy Labs Director Laura McGill recently demonstrated the connector assembly to congressional staff members.