LIVERMORE, Calif. — Researchers at Sandia National Laboratories’ Combustion Research Facility are helping to develop sparkplug-free engines that will help meet ambitious automotive fuel economy targets of 54.5 miles per gallon by 2025.

They are working on low-temperature gasoline combustion (LTGC) operating strategies for affordable, high-efficiency engines that will meet stringent air-quality standards.

Sandia researchers Isaac Ekoto and Benjamin Wolk said the goal of the LTGC project is an engine in which chemically controlled ignition initiates the combustion of dilute charge mixtures.

“The use of dilute mixtures avoids high flame temperatures that can lead to nitrogen oxide formation,” Ekoto said. “LTGC operation increases engine efficiency relative to conventional spark-ignited gasoline engines through reduced heat transfer and pumping losses, along with increased conversion of fuel chemical energy into usable work via higher compression ratios and mixture specific heat ratios.”

Their challenge has been effective auto-ignition control when an engine is idling or at other low-load operating conditions, where slow burn rates can cause frequent misfires.

Their research was published in the September 2015 issue in the SAE International Journal of Fuels and Lubricants in a paper titled, “Detailed Characterization of Negative Valve Overlap Chemistry by Photoionization Mass Spectroscopy.” The work was recognized by the Society of Automotive Engineers of Japan (JSAE) as the best paper of 2015.

Creating negative valve overlap to extend engine operation

One method to improve LTGC engine operation at low loads is to employ a negative valve overlap (NVO) strategy.

“Modified valve timings shorten the exhaust stroke and delay opening of the intake valve, so that most of the combustion products from the previous cycle are trapped in the cylinder and mix with the fresh intake charge during the next cycle,” Ekoto said.

For direct-injection engines, the Sandia team is researching how to enhance auto-ignition further by introducing a small amount of fuel injection during the NVO period. The high temperatures reached during the NVO period — from compression heating of the hot retained burned gases — work to thermally decompose the fuel into a more reactive “reformate” stream laden with hydrogen, carbon monoxide and small hydrocarbons, such as methane, acetylene and ethylene.

Characterizing chemical composition of NVO

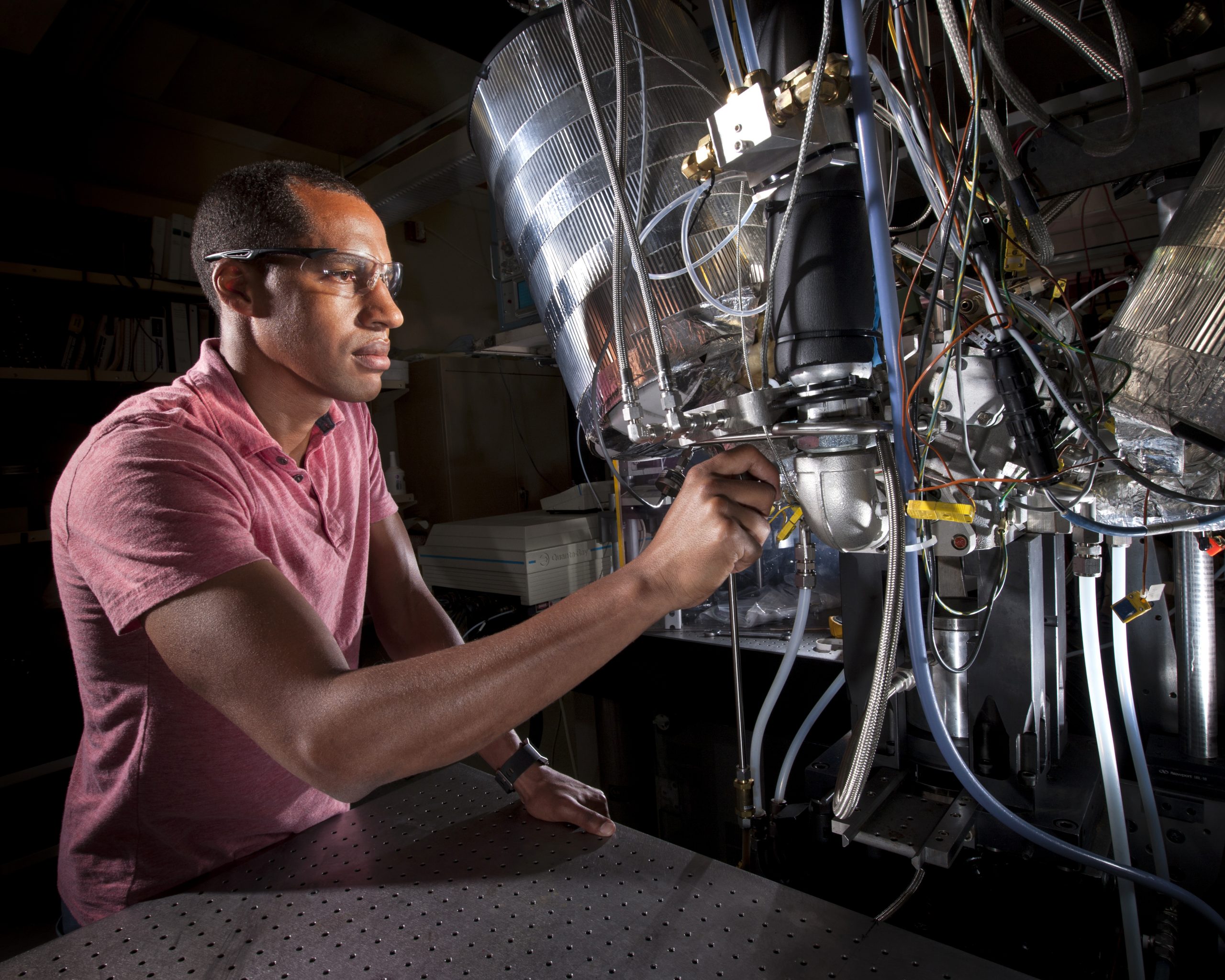

To accurately characterize the chemical composition of NVO-generated reformate and its impact on engine performance, Ekoto and Wolk conducted a series of experiments.

Experiments were performed using six different single-component fuels: iso-octane, n-heptane, ethanol, cyclohexane, toluene and 1-hexene. Each fuel represented the different classes of components found in commercial gasoline. They also evaluated a research-grade gasoline whose composition was well understood and a surrogate that mimicked the research gasoline.

A custom-developed dump sampling valve — designed to fit into an available spark-plug port of a single-cylinder research engine — enabled full-cylinder gas sampling of the reformate. The sampled gas was stored in a cylinder that was pre-heated to avoid hydrocarbon or water condensation and was subsequently fed into a gas chromatograph (GC) to identify the light hydrocarbon species present in the reformate.

“Quantifying the concentrations of these species provides valuable insight into how the fuel chemical energy is distributed among the different classes of light hydrocarbons in the reformate,” Ekoto said.

However, GC measurement doesn’t accurately distinguish between species with similar molecular composition, but that have drastically different effects on auto-ignition chemistry. Nils Hansen and Kai Moshammer of Sandia’s Combustion Chemistry Department helped perform more detailed characterization of the reformate streams via photoionization mass spectrometry (PIMS).

The PIMS measurement, performed at Lawrence Berkeley National Laboratory’s Advanced Light Source, used vacuum ultraviolet light to continuously ionize the sample gas in the extraction region of a high-resolution time-of-flight mass spectrometer. The photon energy of the ionized gas was scanned across a range of relevant energies, with resultant ions extracted and detected on a micro-channel plate detector. The team developed an algorithm that identified sample constituents, based on their photoionization efficiencies.

By combining the PIMS and GC measurements, they evaluated the auto-ignition reactivity of the reformates, with the help of simulations employing detailed chemical kinetic models.

“The reformate generally sped up auto-ignition when blended with the unreformed parent fuel,” Ekoto said, and the team was able to identify a handful of chemical species responsible for the speedup.

They incorporated these results into a simplified engine-cycle model that accounted for the increase in charge-specific heat ratios from the low-molecular-weight reformate constituents and the charge-cooling effect from the main-period fuel injection event. The model demonstrated that increasing the amount of reformate for the gasoline surrogate sped up compression-induced auto-ignition. The researchers said the model agreed well with performance data from the research engine, where they observed that NVO fueling substantially improved combustion stability.

“Predicting the composition of the NVO-period reformate stream continues to be a challenge,” Ekoto said. “Although conventional engine combustion simulations can accurately model flow dynamics, they typically rely on overly simplified combustion models that do not represent the full range of chemical pathways.”

The simplified combustion models do not accurately predict the small concentrations of those constituents that had major impacts on auto-ignition characteristics, however. The team is working with University of Minnesota researchers, who are using the Sandia measurements as benchmark datasets for stochastic reactor models. Those models use simplified mixing models in conjunction with detailed chemical kinetic mechanisms to predict the NVO-generated reformate stream composition.

This research contributes to the Combustion Research Facility’s mission of providing the combustion science and technology base needed to meet U.S. energy needs in an environmentally responsible manner.