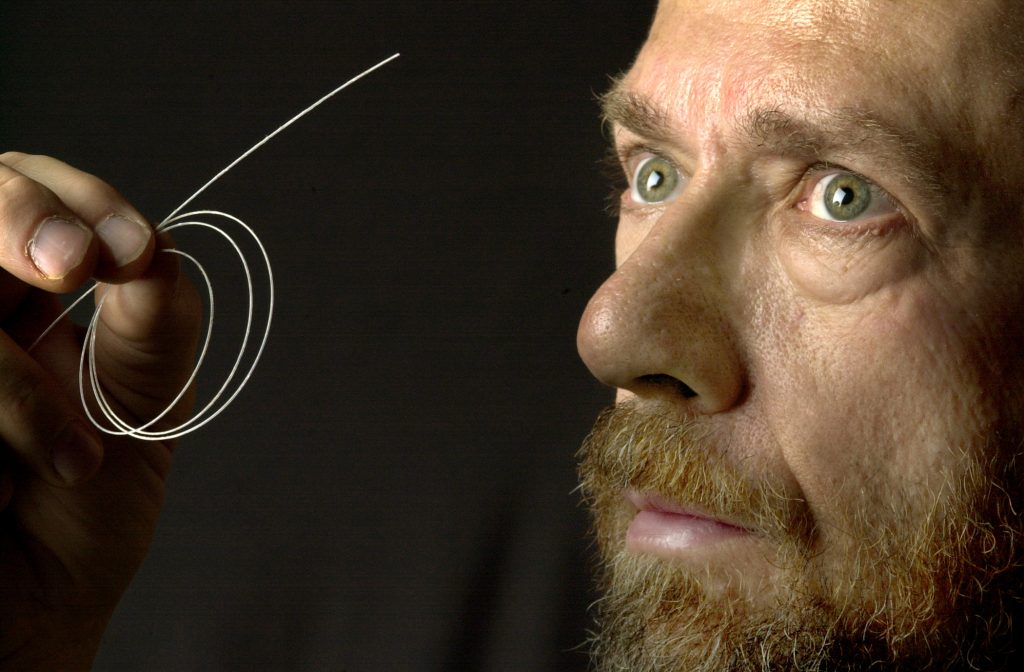

Download 300dpi JPEG image, ‘downholefiberoptic.jpg’, 2MB (Media are welcome to download/publish this image with related news stories.)

ALBUQUERQUE, N.M. — A new technique developed by researchers at Sandia National Laboratories using an inexpensive disposable fiber optics telemetry system to relay real-time information about the drilling process is capturing oil and gas industry attention.

“We have come up with a unique system using throwaway fiber optics that relays information of what is going on at the end of the drill string as it is happening,” says David Holcomb, Sandia researcher who devised the technique. “Information is instantaneously sent to the surface about temperatures, pressure, chemistry, and rock formation — all obtained without stopping the drilling operation.”

Sandia is a Department of Energy laboratory.

Holcomb conceived the idea of a disposable cable about eight years ago at an oil and gas industry meeting. People there indicated the need for immediate access to information about the drilling process and the formations being drilled. They wanted to obtain data without halting the drilling operation and have it be transmitted to the surface immediately at a rate high enough to support video systems.

“Traditionally to gather this type of information, drilling would have to be stopped so that instrumentation could be lowered into the drill hole,” Holcomb says. “Ceasing the drilling process is extremely expensive — as much as $100,000 to $200,000 a day for off shore drilling. A better way was needed.”

Familiar with disposable fiber developed for the non-line-of-sight missile guidance systems in the 1980s, he realized the technology might be applied to well drilling.

Using fiber optics telemetry to transmit information from the down-hole end of the drill string while drilling is in process has been of interest to the oil and gas well drilling industry for some time. However, it was considered expensive. A bulky armor was required to protect the delicate optical fiber, and deploying the cable interfered with drilling. Holcomb’s technique, instead, uses unarmored fiber, protected only by a thin, clear protective plastic coating, similar to that found in missile guidance systems that can deploy miles of fiber from a small spool at missile speeds.

“The key difference from other attempts to insert fiber optic cable in drill pipes is to consider the cable a throwaway item, to be used once and then ground up and flushed out in the drilling mud,” Holcomb says. “If the cable only has to survive for a few hours and need not be retrieved, it is feasible to use ‘unarmored’ fiber, which is cheap and can be wound into packages small enough to be inserted into the drill pipe without interfering with operations.”

The extreme lightness and compactness of the unarmored optical fiber makes it easy to manipulate, compared to the massiveness of a conventional reusable cable. The fiber flows through the drill string with the mud to reach the bottom of the hole where it instantaneously sends back information to drill operators.

Actual oil and gas drill holes are about eight to ten inches, or larger, in diameter. The pipe (drill string) running down the middle of the hole through which the mud flows is about five inches. To deploy and control the optical fiber in the rapidly moving mud in the drill string, researchers developed a deployment tool. The optical fiber is wound up like a spool of thread inside the tool, which controls the payout of the fiber into the drill string. The entire deployment tool weighs about 75 pounds; the actual fiber optics being placed into the drill string weighs only about one pound.

Holcomb said he and other researchers successfully showed that the disposable fiber optics telemetry system works in tests last September at the GRI/CatoosaSM Test Facility, Inc., a subsidiary of the Gas Technology Institute (GTI), located in Catoosa, Okla.

“We got the fiber down and the information back all successfully,” he says. “While in field tests the optical fiber was dropped only 3,000 feet, we see no limitations. The cable could easily reach 10,000 to 20,000 feet.”

Researchers had two primary concerns going into the test. They were worried that the abrasive nature of the mud flowing through the drill string would chew up the fiber. They also were concerned that the drag of the mud flow down the drill hole would break the fiber.

Both concerns turned out to be inconsequential.

“The abrasiveness was not a problem,” Holcomb says. “The fiber doesn’t fight. It has a light plastic coat that gives. It doesn’t resist abrasive particles.”

The second concern, drag, also proved not to be a problem. Laboratory drag measurements over-predicted the drag by a factor of two or three. The researchers aren’t quite sure why the inconsistencies between the lab tests and the field tests exist. One possibility might be that the fiber moves to the wall of the drill string, out of the way of the mudflow.

Researchers also determined the new system could transmit data at about one megabit per second, 100,000 times faster than commercially available MWD (measure while drilling) transmission systems, without interfering with the drilling process.

GTI funded recent research after Sandia funded the early work. Currently GTI is seeking a partnership from the oil and gas industry to put the new inexpensive disposable fiber optics telemetry system into production.

“There’s been a lot of interest,” Holcomb says. “This could change the future of oil and gas drilling around the world.”

Technical contact:

David Holcomb, djholco@sandia.gov, (505) 844-2157