Download 40dpi JPEG image, ‘brinker_birds.jpg’, 76K (Media are welcome to download/publish this image with related news stories.)

ALBUQUERQUE, N.M. — Intelligent nanostructures that report on their environment by changing color from blue to fluorescent red under mechanical, chemical, or thermal stress have been created by researchers at Sandia National Laboratories and the University of New Mexico.

Most immediately, the self-assembling structures — as durable as seashells — may lower costs by reducing the need for expensive manufactured devices like stress detectors, chemical analyzers, and thermometers. “The material can distinguish between different solvents,” says Sandia senior scientist and UNM professor Jeff Brinker. “There’s a high correlation of color with the polarity of the solvent.”

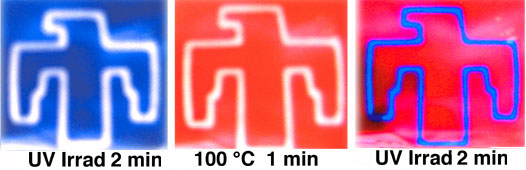

The material also can report changes in mechanical stress and temperature. When the environmental disturbance is removed, the structures change back to their original color in some cases, making them potentially reusable.

“The material is of interest to NASA — one of the sponsors of our research — for a thin film for an inflatable structure that would aid in the inhabitation of Mars,” says Brinker. “The structure’s skin would require a very thin yet strong membrane with low permeability that could sense mechanical damage from hazards such as meteorites or sandstorms.”

The color change of the coating would also be sensitive to the composition of chemicals hitting the structure’s “skin,” or to dangerous increases in temperature.

The elegantly simple method, which involves a technique that links monomers into polymers in an orderly fashion within a nanostructure, is published this week in the April 19 Nature.

Another possible use for the orderly arrangements is to form nanoscopic “wires” of organic polymers.

In seconds, robust housing for conjugated polymers

Underlying the immediate application described above, the Sandia/UNM method is a generic, efficient solution to a problem that has puzzled modern materials science: how to efficiently distribute conjugated polymers — inexpensive carbon-based polymers that due to special bonding patterns carry electrical current and produce changes in a material’s optical properties — within a hard, protective structure.

Conjugated polymers are prominent enough scientifically that the Nobel Prize was awarded this year to Alan J. Heeger (Univ. of Calif. at Santa Barbara), Alan G. MacDiarmid (Univ. of Pa.), and Hideki Shirakawa (Univ. of Tsukuba, Japan) for initially developing the field. In 1977, they oxidized polyacetylene (a solid polymer prepared from the flammable gas acetylene) with iodine to yield a material many times more electrically conductive than the untreated, semiconducting polyacetylene.

But a still-open question is how best to fashion a structure for these potentially useful but fragile extended molecules.

“Traditionally, bulk conjugated polymers are like a huge bowl of entangled spaghetti,” says Brinker. “Our method organizes this jumble by forcing them to adopt a particular conformation; that is, we organize them into nanostructures. We can force them into conformations, and so define where the polymer is and isn’t. Then we can control how interactions between polymer units will affect a material’s electrical and optical properties.”

A robust architecture that’s optically transparent and prevents oxidative degradation of the polymer can be patterned on surfaces and substrates.

“This is a simple means of forcing organization that should help us integrate conjugated polymers into devices,” says Brinker.

Conjugated polymers ‘while u wait’

It takes only seconds for the Sandia/UNM method to evenly pre-distribute monomers — simpler precursors of polymers — within a silica matrix through self-assembly. Exposure to UV light polymerizes the monomers into conjugated polymers housed in nanoscopic channels that penetrate the matrix of the material.

The result is a nanocomposite that is mechanically robust, optically transparent, and produces telltale changes of color under changing environmental conditions.

Technical discussion

Sandia researchers Alan Burns and Darryl Sasaki had characterized the responsiveness of two-dimensional films of these polymers to local stresses and temperature changes. However, their work, published last year in the American Chemical Society journal Langmuir,showed the organic materials to be “soft” and lacking the robustness required in harsh environments.

While this problem could be solved by incorporating the polymers in “hard” silica scaffolds, previous research groups at other institutions had found that implanting conjugated polymers into pre-existing silica structures to be a time-consuming, inaccurate, and relatively expensive process.

A significant step was performed by Sasaki, who was able to synthesize the precursor monomer of the polymer so that it became both substance and scaffold. His synthesized two-sided (detergent) molecule served as both the structure-directing agent for self-assembly and as the monomer of the conjugated polymer polydiacetylene. The method to self-assemble the detergent molecule with silica to form a nanocomposite was discovered by UNM postdoc Yi Yang and former Sandia postdoc and UNM graduate student Yunfeng Lu.

The self-assembly method is based on the scientifically well-known tendency of two-sided detergent molecules, composed of hydrophilic (water-loving) and hydrophobic (water-hating) portions, to spontaneously form spherical molecular assemblies and periodic three-dimensional nanostructures in solutions of water.

In the Sandia/UNM process, evaporation, exposure to ultraviolet light, and a low-temperature heat treatment polymerizes the organic surfactant monomers and the surrounding silica nanostructure. This process was used originally by Brinker and colleagues to fabricate a structure that mimicked the layered hard-soft construction of seashells.

In the current work, it is the polymers themselves — already evenly distributed through self-assembly — that are of interest. By compartmentalizing them within the aligned periodic pores of a silica nanostructure, it should be possible to align them and to control charge and energy transfer between them while providing mechanical and chemical stability.

Sandia’s Laboratory-Directed Research and Development program, the Department of Energy’s Office of Science, NASA and the Air Force Office of Scientific Research co-funded this work.

Thin films, nanoscopic spheres, intelligent ink, light-alterable pore sizes

The achievement is the group’s latest in making use of self-assembling two-sided molecules. The earliest, simplest version of the method was first reported in Naturein September 1997. In that paper the group described how detergent molecules, alcohol, silica, and water could be used to self-assemble a thin film with precisely defined pores for membranes, sensors, and low-k dielectrics.

Since then, this inexpensive process has been used in increasingly complex procedures, all reported in Natureand in Science.The process has produced a seashell-like layering at once very strong and nonbrittle, nanoscopic spheres that can hold catalysts or medicine, intelligent ink that assembles during ink-jet printing, and self-assembled nanostructures with pore sizes alterable by light to a fineness of 0.2 angstroms.

Sandia research contact:

Jeff Brinker, cjbrink@sandia.gov , (505) 272-7627