ALBUQUERQUE, N.M. – Sandia researchers have developed a process that can mix tiny volumes of liquid, even in complicated spaces.

Researchers currently use all types of processes to try and create mixing, with only “mixed” success. “In small devices,” says Sandia materials scientist Jim Martin “people have tried all kinds of pillars and mixing cells to initiate mixing, but these approaches don’t work well.” Researchers need simpler and more reliable ways to mix in tiny places such as micrometer-sized channels, Martin said.

“Mixing liquids in tiny volumes,” Martin said, “is surprisingly difficult.” When fluid is pushed down a big pipe, eddies are generated that create mixing. But if fluid is pushed down a small pipe no eddies are generated and mixing does not occur unless you subject the fluid to tremendous pressure, which isn’t usually easy or feasible, he said.

Martin’s discovery of how to mix tiny liquid volumes arose from LDRD-funded research directed at improving the sensitivity of the chemical sensors developed in his lab. That project, “Field-Structured Composite Studies,” was a joint effort with Rod Williamson (now retired). While their LDRD project did not lead to the expected results, Martin and Williamson were surprised by the wide variety of physical effects they discovered along the way, including magnetic mixing. These effects, Martin said, ended up being much more interesting and important than the original goal.

Since the project began, Department of Energy’s Division of Material Science and Engineering, Office of Basic Energy Sciences, has started a new project whose goal is to better understand the fundamental science of field-structured composites. So the program succeeded even as it failed, and eventually Martin and graduate student intern Doug Read developed better ways to increase sensor sensitivity.

In the new method of mixing, when one turns on a particular kind of magnetic field, the magnetic particles suspended in the fluid form chains like strings of pearls. The chains start swirling around and that’s what does the mixing. The particles are then removed magnetically, leaving a nice mixed-up liquid.

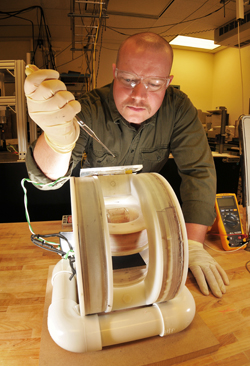

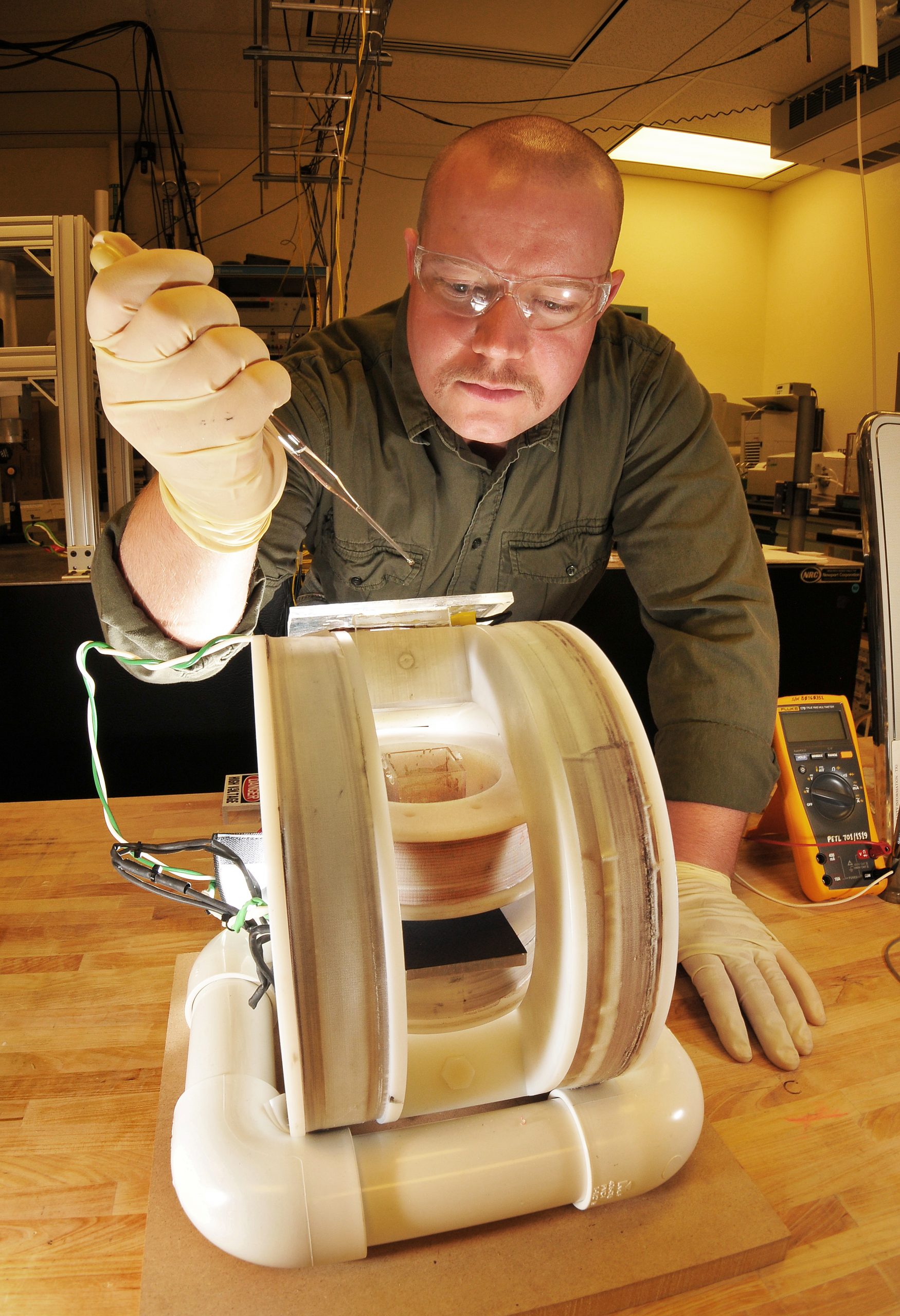

More technically, the new mixing method, which Jim calls vortex field mixing, subjects a suspension of microscopic, magnetizable particles to a magnetic field whose direction is constantly spinning in a motion similar to a spinning top as it is about to collapse on its side, but much faster. In this “vortex field” the particles assemble into countless microscopic chains that follow the field motion, stirring every nook and cranny of the fluid. The vortex field stirs the liquid vigorously, and surprising fluid effects are possible, such as a kind of washing machine agitation where the spinning direction alternates periodically.

Currently, Martin, Lauren Rohwer, and graduate intern Kyle Solis work with the vortex field mixing, among other projects. Their experimental report, recently appearing in the July issue of Physical Review, has generated interest, including a Physical Review Focus article and a Research Highlight in the September MRS Bulletin.

This type of magnetic mixing with particles that assemble into micro-stir bars isn’t like the magnetic mixing done in high school chemistry class.

“In your high school chemistry class,” Martin says “when you mixed a beaker of water on a stir plate, underneath the plate was a permanent magnet spinning around to make the stir bar spin. If that hidden magnet suddenly became twice as strong, the magnetic field would double but you wouldn’t see any increase in the stirring at all.

“With our process,” Martin said “if we make the magnetic field twice as strong, the stirring becomes four times as strong because the stronger field makes the particle chains longer.”

With conventional stir-bar mixing you can increase the mixing torque by increasing the speed of the stir bar instead. It’s easy to feel this effect by simply holding the beaker slightly above the stir plate. In vortex field mixing increasing the speed of the wobbling doesn’t help, because the chains simply break into smaller pieces and the mixing torque doesn’t change at all.

Vortex field mixing stirs just as effectively with magnetic nanoparticles as with traditional micrometer-size powders. In fact, excellent mixing torques have been obtained using 100 nanometer particles. This means even the tiniest fluid volumes can be mixed, as well as the largest.

As strange as these effects are, they were initially predicted by Martin in a theory paper published in the January 2009 issue of Physical Review. This paper also explains why a simple rotating magnetic field doesn’t induce mixing, and predicts the optimal wobbling angle of the magnetic field.

Vortex field mixing requires only the modest magnetic fields provided by simple wire coils that can be scaled to the size of the fluid cavity. After mixing, a researcher can trap the particles with a permanent magnet, decant the mixed liquid and recycle the particles endlessly.

This work was supported by the Division of Materials Science and Engineering, Office of Basic Energy Sciences, U.S. Department of Energy (DOE).