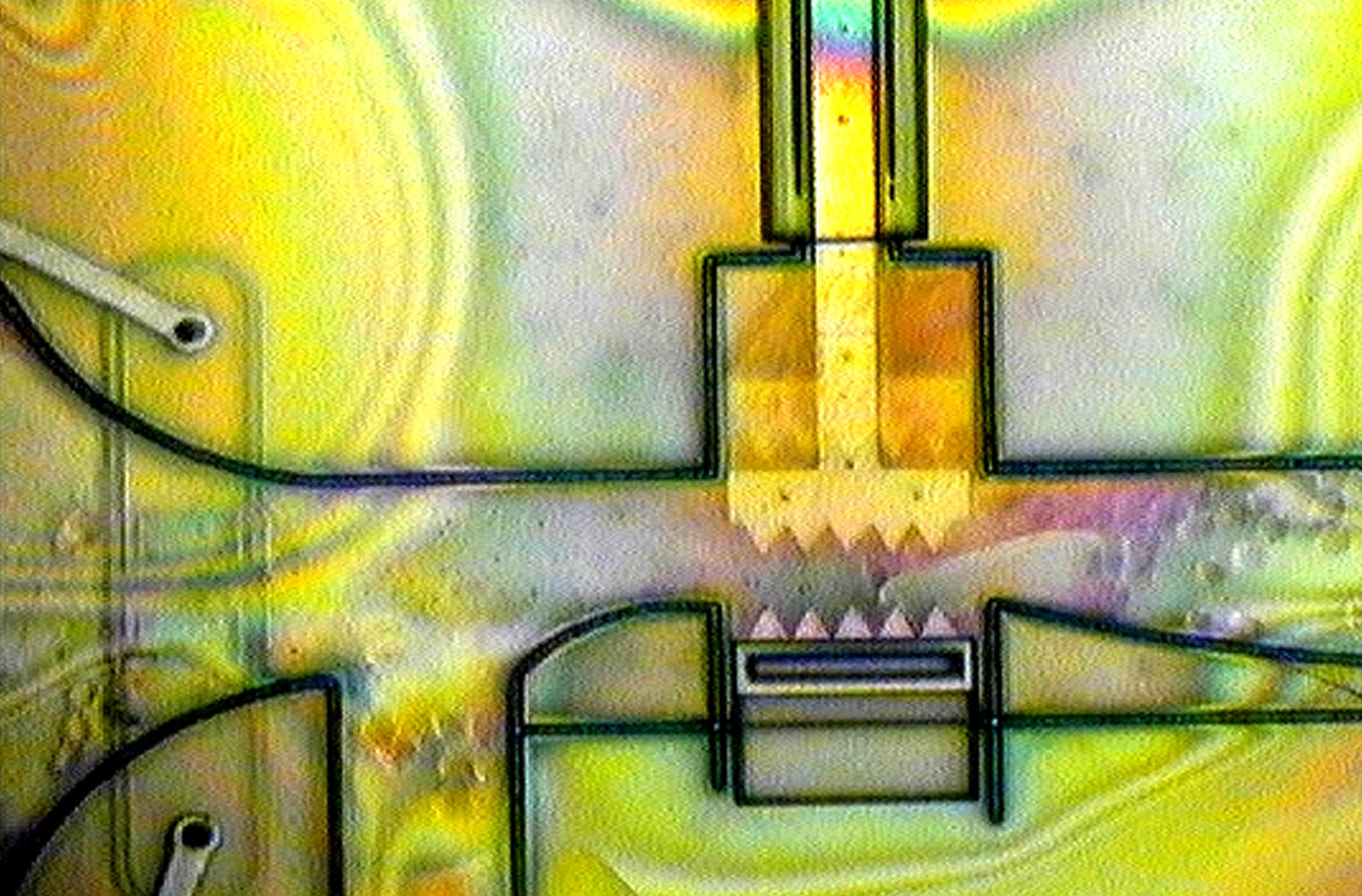

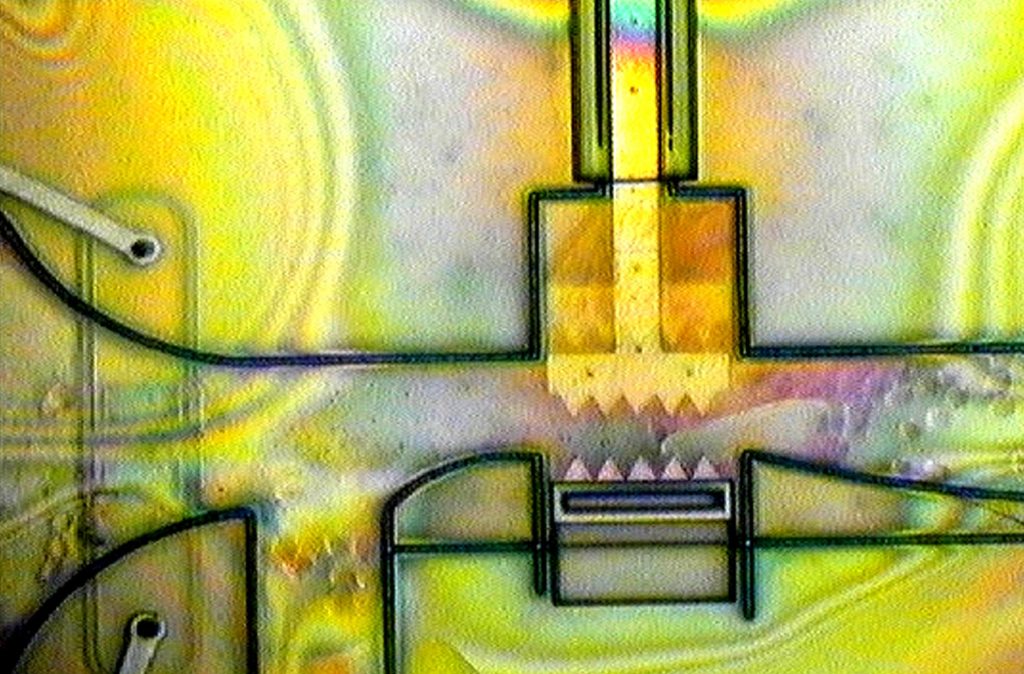

Download 300dpi JPEG image, ‘Pacman.jpg’, 424K (Media are welcome to download/publish this image with related news stories.)

ALBUQUERQUE, N.M. — Silicon microteeth that open and close like jaws have been developed at Sandia National Laboratories. The microjaws fit in a microchannel about one-third the width of a human hair (about 20 microns wide). When the jaws close, they trap a red blood cell — one of many being pumped through the microchannel like tomatoes spilled from a basket. The jaws, which open and close very rapidly, deform captured cells, and then, in less than the blink of an eye and almost playfully, let the little things loose. The blood cells travel on, regain their former shape and appear unharmed.

“We’ve shown that we can create a micromachine that interacts at the scale of cells,” says Sandia researcher Murat Okandan. “We’ve created a demonstration tool with very flexible technology that we believe will enable many designs and concepts. This device itself may generate considerable interest from the agriculture or genetic engineering marketplaces.”

The ultimate goal of the Sandia device is to puncture cells and inject them with DNA, proteins, or pharmaceuticals to counter biological or chemical attacks, gene imbalances, and natural bacterial or viral invasions. The devices can be mass-produced easily and cheaply through computer-chip production techniques.

The device, because of its constant munching, bears a strong resemblance to the computer game hero Pac-Man, which also munched creatures travelling along small channels. In this case, the “upper” teeth of the microdevices slide back and forth in piston-like action across the microchannel to momentarily trap individual red blood cells against the lower teeth.

Stem cell interactions a possibility

The cells punctured do not need to be blood cells but could be, say, stem cells — cells able to change, given suitable direction — possibly by gene implantation — into many of the tissues of the human body, says Okandan.

The capability to implant materials in cells would have large implications for the multibillion-dollar microfluidic device industry, currently capable of analyzing biofluids but not altering them.

The prototype, patent-applied-for devices offer the possibility of considerable mechanical intervention at the cellular level because they operate rapidly and are so small that many units could operate in parallel in a relatively compact volume. Ten complete units fit in an area smaller than a household electric plug prong, and each microdevice can puncture 10 cells per second.

An immediate goal of Okandan, who developed the device with Paul Galambos, Sita Mani, and Jay Jakubczak, also of Sandia National Laboratories, is to see whether the ruffled red blood cells absorb a fluorescent material the group has already shown the cell naturally rejects.

If the material is readily absorbed, it means that Sandia researchers have created the first reported example of a continuous flow, mechanical cellular-membrane disrupter.

A further but still near-time goal is to replace the microteeth with a hollow silicon needle now in development. The needles would rapidly inject DNA, RNA, or proteins (including drug molecules) into living cells at precise points of their anatomies and in large numbers, possibly changing the course of a disease or restoring lost functions.

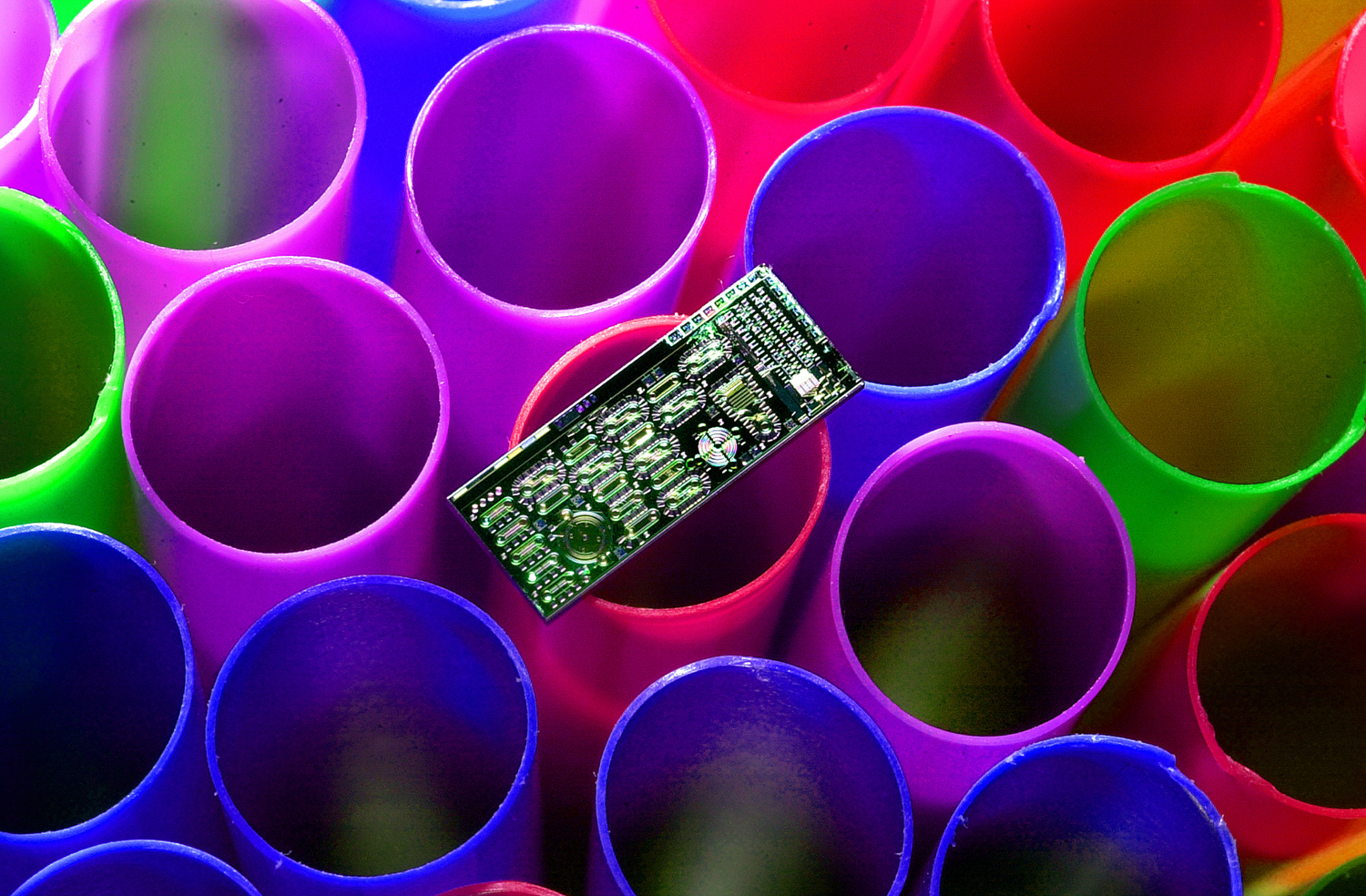

Download 300dpi JPEG image, ‘Microfuidicdevice.jpg’, 1.5MB (Media are welcome to download/publish this image with related news stories.)

The depth and precise position of molecular insertion would be controlled by researchers who have located the cell’s “sweet spot” by observing effects of the insertions.

Hundreds or thousands of units assembled in parallel, puncturing cells at the rate of 10 a second, could create a sizeable supply of enhanced material.

Current methods of cell implantation use electric fields to open cell walls for chemical absorption. A problem with this method, called electroporation, is that it causes the overwhelming proportion of cell populations to die. Other manual methods exist in which genetic material is delivered into cells one by one through a very fine pipette — a labor-intensive and specialized process. Sandia’s Pac-Man device has the possibility of overcoming both of these problems.

Why the device could be built

Inexpensive fabrication of the device became possible for two reasons: the unique capabilities of the Sandia MEMS SUMMiT V fabrication process — a sequence of deposition, patterning, and etching steps — used to create complicated micromachines, and the use of silicon nitride to build insulated microchannels in that process. The process uses standard integrated circuit technology.

An effective insulator is needed because microchannels of silicon, an electrical conductor, would short out electrodes that create electrical and magnetic fields used to analyze or manipulate the contents of the channel. By fabricating channels instead out of a version of silicon nitride, the researchers can avoid these problems.

Silicon nitride’s other advantages are that it is transparent, allowing researchers optical examination of the experiments, and that it is a material commonly used in microelectronic device fabrication — an important consideration.

Although the microdevices are fabricated step by step with lithographic processes well known to the semiconductor industry, the ability to easily make this complicated device is credited to the Sandia SUMMiT V fabrication process, which allows five-level micromachine construction to be quickly designed and implemented. The SUMMiT V process is the only one available worldwide that can construct five-level micromachine devices.

Another invisible ingredient in the mix was Sandia’s expert MESA (Microsystems and Engineering Sciences Applications complex) fabrication teams that physically created the device.

Technical background:

A microfluidic device typically consists of thousands of channels conducting tiny amounts of fluids for analysis. The channels’ widths are measured in 10’s to 100’s microns. One-thousandth of an inch is 25 microns. An integrated device of this type, operated by a technician or automatically, can greatly enhance the efficiency at which multiple tests can be performed. The device also greatly reduces the amount of material (expensive chemicals) needed for testing. The market for such devices is currently reported in the billion-dollar range.

Sandia Technical contacts:

Jay Jakubczak, jayj@sandia.gov , (505) 844-9196

Murat Okandan, mokanda@sandia.gov, (505) 284-6624