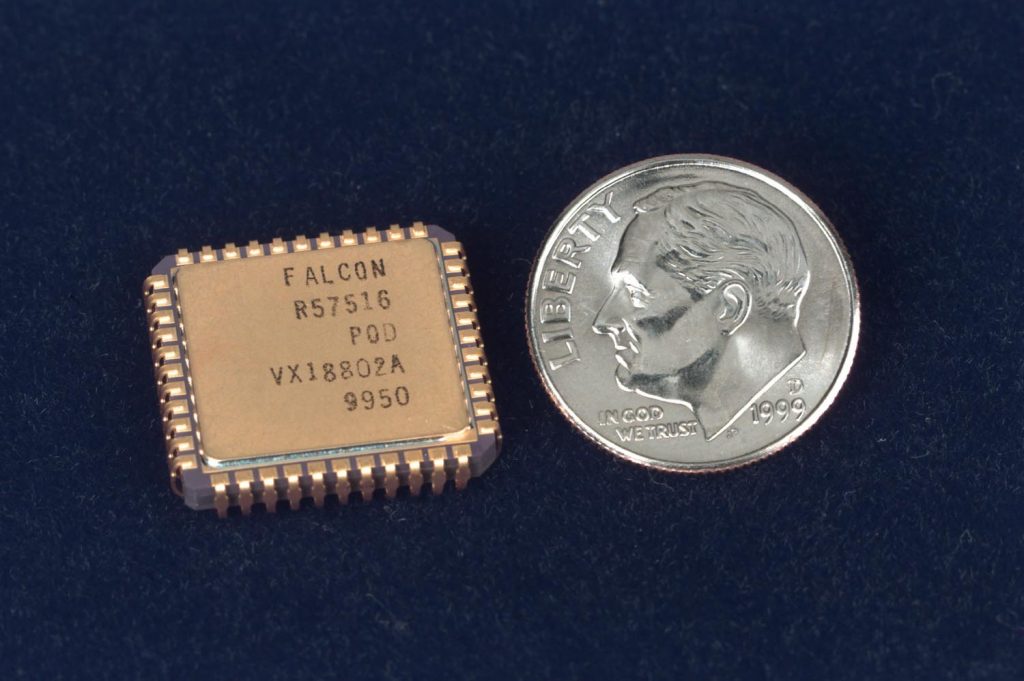

Download 300dpi JPEG image, ‘falcon_dime_2.jpg’, 132K (Media are welcome to download/publish this image with related news stories.)

LIVERMORE, Calif. — Sandia National Laboratories engineer Ken Condreva has built a better stopwatch. It’s smaller than a dime, accurate to 125 picoseconds, and can be produced far more inexpensively than comparable devices.

The inspiration for his invention was the need to accurately record critical timing signals in weapon test flights. New telemetry systems required a compact, lightweight and low-power device for this purpose.

“The only things I could find that had this resolution were table-top instruments packaged in a box,” Ken said. “They were way too big, and used way too much power.”

His invention became the FALCON, an integrated circuit that uses his patented “Pulse Stretcher” technique to increase resolution up to 200 times for a low-power electronic clock (using 300 mW at 40 Mhz). The circuitry provides greater resolution by lengthening duration of the output signal, making it last from 64-200 times longer than the input signal. Although the input pulse is “stretched” in real time, the technique can be compared to recording a sporting event with fast-action film and replaying it at slow speed to clearly see what happened.

Reasoning that a compact way to count time intervals at high resolution with low power would be useful commercially, Ken obtained a patent in 1994.

Applications that might benefit from such a device include those that rely on measuring distances accurately, such as land surveying; construction; testing, assembly and manufacturing; liquid level measurements in chemical and petrochemical plants; and collision detection and avoidance in vehicles, said Sandia National Labs business developer Scott Vaupen. This timing device accurately operates not only in “normal” working conditions, but also in extremely rugged and harsh environments — high and low temperatures, high vibration and shock, as well as high and low humidity. Small and inexpensive battery-operated monitors could also be devised for future innovative uses.

The integrated circuit uses standard commercially available CMOS technology and could be inexpensively manufactured by most semiconductor businesses, he added.

Sandia is currently seeking commercialization partners with the imagination to exploit this robust and innovative technology. Inquiries should be addressed to Scott Vaupen (925) 294-2322 or e-mail (sbvaupe@sandia.gov).

Technical Contact:

Ken Condreva, kjcondr@sandia.gov, (925) 294-2362