Sandia gas sampling device rapidly determines whether MEMS seals are effective

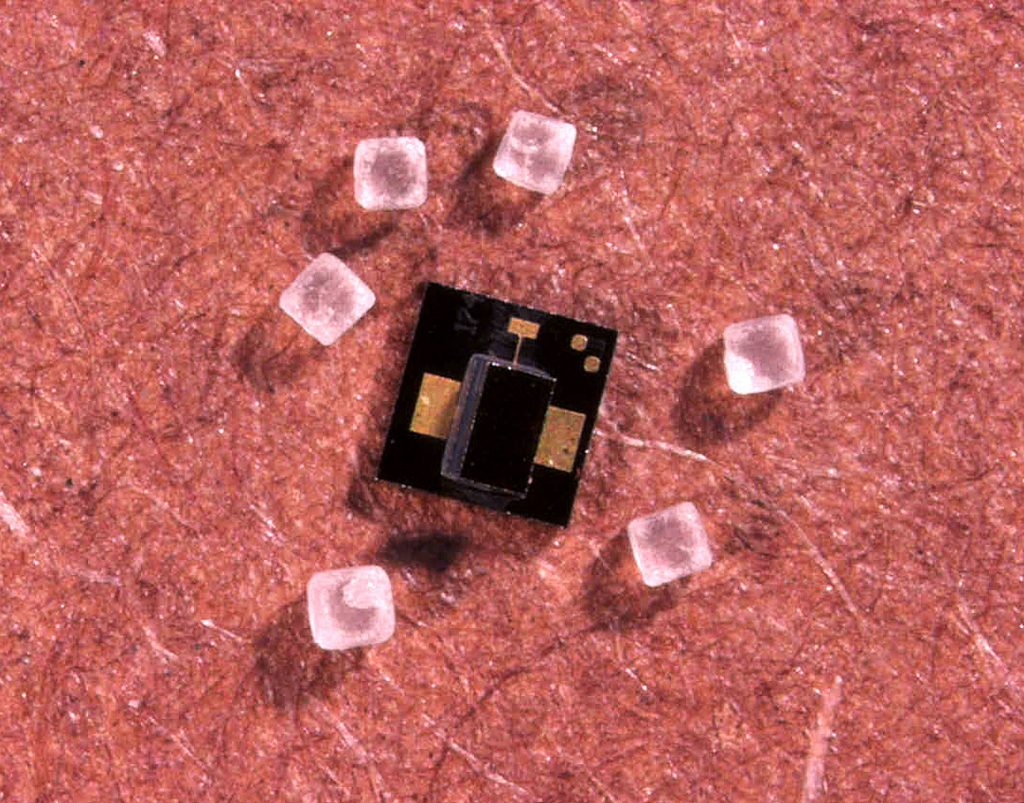

ALBUQUERQUE, N.M. — Just as astronomers want to understand the atmospheres of planets and moons, so engineers want atmospheric knowledge of worlds they create that are the size of pinheads, their “skies” capped by tiny glass bubbles.

Should their silicon inhabitants — microcircuits, microgears, and micropower drivers — exist in a vacuum? An atmosphere of nitrogen? Air as we know it? More importantly, whatever atmosphere was intended, how long will it stay that way? Is the protective barrier hermetic or will its atmosphere change over time, potentially leading to the early death of the device? Will water vapor seep in, its sticky molecules causing unpredictable behavior? What, in short, can we say about how long this little world and its inhabitants will survive and function?

The most advanced sampling procedure known — requiring only picoliters of gas to evaluate the contents of these small atmospheres — is now in place at Sandia National Laboratories, a National Nuclear Security Administration facility. The method was recently revealed at the SPIE Photonics Meeting in San Jose, Calif.

“I know of no one, anywhere else, who can do this kind of testing,” says Sandia innovator Steve Thornberg.

John Maciel agrees. Chief Operating Officer of Radant MEMS, a three-year-old start-up company in Stow, Mass., he is under contract with DARPA to develop high-reliability MEMS (microelectromechanical) switches for microwave devices and phased array antennas. He also sees markets for his MEMS switches in cell phones.

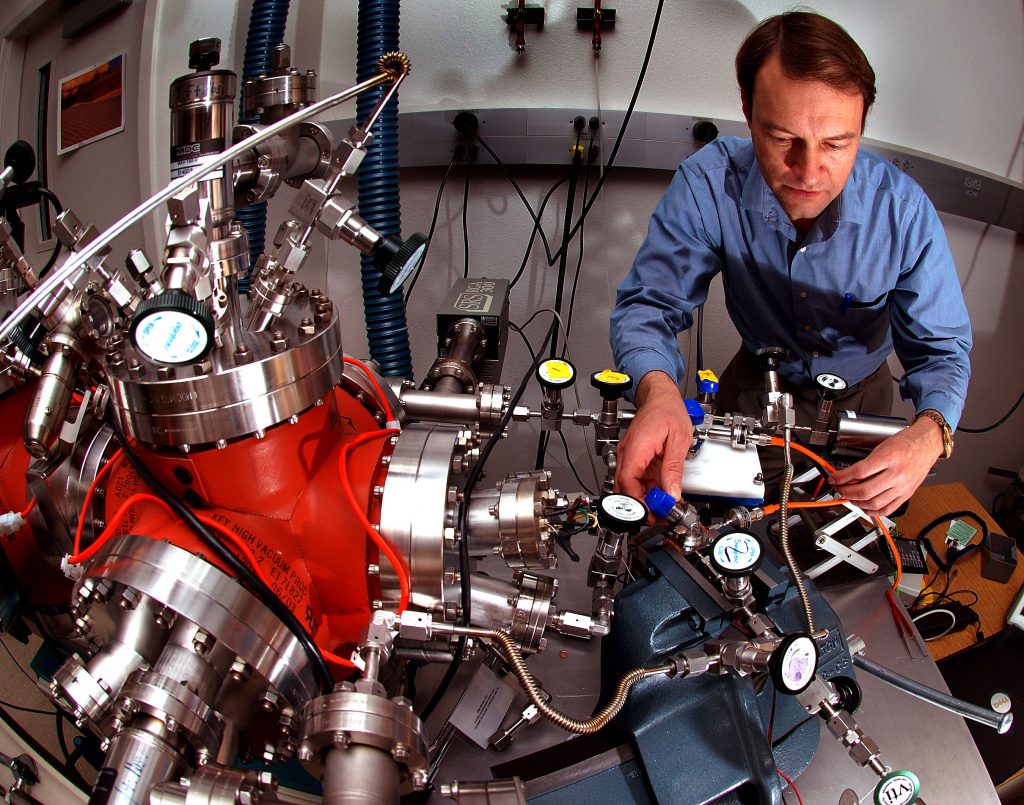

The Sandia method — funded by its Laboratory-Directed Research and Development program, and presented for consideration to Sandia’s patent office — involves a small commercial valve that comes down like a trash compactor and crushes a tiny device until it releases its gases — currently, about 30 nanoliters — into a custom-built intake manifold.

Because Thornberg’s test mechanism requires only picoliters, his sensitive device can recheck its own measurements — using bursts of gas delivered in a series of puffs — dozens of times from the same crushed device in a 20-minute time span.

The method thus provides statistically significant atmospheric measurements at any given moment in a component’s life cycle.

(Current industry tests can achieve at best only a single reading from the release of nanoliters of gas. A single, statistically unverified result may contain significant error.)

By waiting a longer period of time — weeks, or even months — other microdevices from the same batch can be crushed and then analyzed to see what changes have occurred in their atmosphere over time.

Currently, the system is able to measure gasses emerging in pressures ranging from one atmosphere to .0001 torr. (One atmosphere is 760 torr.) The group hopes soon to decrease its lower sensitivity limit to .000001 torr — in effect, to be able to measure the quality of vacuums.

Says Sandia researcher Danelle Tanner, who describes herself as “a reliability-and-aging mechanism physicist” working on a silicon re-entry switch, “We want 100 percent nitrogen [atmosphere] in our device. Steve’s group gave us a really good idea of what species other than nitrogen were present in the package.”

“Maintaining the integrity of the internal atmosphere of a hermetic device is essential for long-term component reliability,” says Thornberg. “It is within this environment that all internal materials age.”

Success of his group’s new investigatory technique lies in the details of the test mechanism.

A precisely machined sample holder holds the MEMS package to be crushed within the sampler valve. If the sample holder is too low, the part would not crush the MEMS device; too high, and the device would crush prematurely, letting gases escape unmeasured.

Because tested devices come in many sizes, height adjustments to the crushing mechanisms are needed for each sample.

The problem of debris from the smashed part interfering with gases that must pass through tiny tubes was solved by sintering a filter into a central gasket.

Perhaps most important, manifold volumes were minimized to maximize pressures when MEMS-released gases expand, reducing the amount of gas needed for an analyzable puff.

Still ahead is success in measuring very small amounts of moisture, which stick to manifold walls without making it to the detector.

To overcome this problem, the Sandia group is working with Savannah River National Laboratory to incorporate that lab’s optical moisture measurement techniques based on surface plasmon resonance (SPR). In that technique, an optical fiber is used to transmit light from a specially coated lens. Moisture levels are measured from wavelength shifts.