ALBUQUERQUE, N.M. — One of Sandia National Laboratories’ core missions is to help the world through innovation.

However, transferring some of that innovation from the Labs to industry isn’t always an easy process.

Through hard work and ingenuity, some Sandia employees are excelling at moving technology to market, a feat that is now being honored by the Federal Laboratory Consortium. The consortium, composed of more than 300 members nationwide, provides a forum to develop strategies and opportunities for linking laboratory technologies and expertise in the marketplace.

Regional Technology Transfer Award: Disinfectant 2.0

The winner of the 2024 Federal Laboratory Consortium Technology Transfer Award for the mid-continent is Disinfectant 2.0. It’s a product that kills viruses, bacteria and fungi for long periods and was developed in the middle of the COVID-19 pandemic using technology developed at Sandia.

It’s the creation of materials scientist Hongyou Fan and his team, along with the company Lunano, LLC, based in McLean, Virginia.

Fan started working with Lunano in January 2020 as part of the FedTech Startup Studio program to explore how to use nanomaterial technology developed at Sandia for disinfectant applications. When the pandemic hit, that partnership kicked into high gear.

Lunano CEO and co-founder Bradley Duckworth said he remembers a conversation he had with a Lyft driver:

“We talked about the challenges the company was facing trying to keep their drivers’ cars disinfected for customers,” Duckworth said. “I asked him, ‘well, if you were able to have a product that didn’t give your customers headaches and wasn’t unpleasant to smell and it worked continuously, would this be something that would be interesting for you?’ He said, ‘Absolutely.’”

That was all the convincing the team needed to get to work quickly. They reached out to more industries, including hotels, restaurants and airlines and realized the great need for such a product and how it could help everyday life.

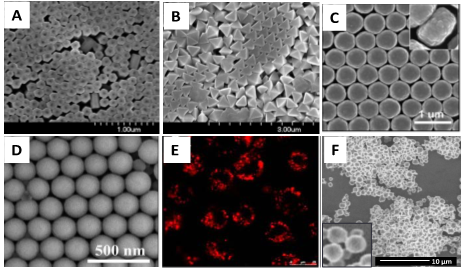

From that point, Duckworth, Fan and their teams decided to pursue a process called detergent-assisted fabrication of porphyrin nanoparticle photosensitizers.

How it works

Porphyrins are photo pigments that, when exposed to light, go through a chemical reaction.

The team assembled these porphyrins into nanomaterials that can be integrated into sprays, compounds and membranes, as well as in manufactured surfaces.

When they are exposed to light, the chemical reaction is triggered, releasing a highly reactive species that kills disease cells, including E. coli, Staphylococcus aureus, staph infection, viruses, bacteria and fungi. While disinfectants generally must be reapplied to high-touch surfaces regularly, Disinfectant 2.0 has a months-long to a years-long life span.

“The beauty of this is that light is the trigger,” Fan said. You have light everywhere and it’s free. Take a taxi for example; in it you have customers who bring germs. You spray Disinfectant 2.0 onto the car seat’s surface and when the light hits it, you kill the germs.”

Getting it commercialized

Creating the product is just the first step. Often, one of the hardest steps is getting it to industry. This team worked together to get the technology licensed quickly and under extraordinary circumstances.

The teams spent hours working together online because of the COVID-19 pandemic and health restrictions, all while still doing their day jobs.

“When they started, there were so many uncertainties,” said Robert Westervelt, a licensing executive with Sandia who worked on the project. “They went through trainings and did some 500 interviews. They found a good patent attorney and found angel investors.”

Lunano was then able to license the technology at no cost under a special license Sandia created during the pandemic.

Lunano is now conducting research with large companies to determine how to best integrate Disinfectant 2.0 technology into their products and how to produce it on a mass scale. They’re planning to create 100 jobs in the process.

Leaving a mark on the world

This technology is poised to have a lasting effect.

“I think it’s one of the top technologies that I’ve had the ability to help commercialize just because of the breadth of its impact,” Westervelt said.

Fan said he’s excited to see where it goes from here.

“Years ago, when I started this work at Sandia, I was focused only on the fundamental science side,” he said. “When the pandemic hit, we realized what a huge impact our work could have on the world, especially during a time of crisis. Now I feel so excited. You don’t know what a big a deal this science can be in the future.”

Fan, who was recently named a fellow of the American Chemical Society continues to tackle new challenges over a wide range of applications including nanoelectronics, energy and materials integration.

He currently manages Sandia’s Geoscience Core Program for the Department of Energy’s Office of Science Basic Energy Science. He is also the manager of the Geochemistry department, a group of scientists who are addressing national problems in CO2 reduction, hydrogen storage and critical minerals recovery to address the Bipartisan Infrastructure Law. In this work they are helping to establish secure sustained domestic critical minerals supply chains.

Outstanding Tech Transfer Professional

The Federal Laboratory Consortium has also named Sandia’s Chief Intellectual Property/Patent Counsel Samantha Updegraff as Outstanding Tech Transfer Professional of the Year for her ability to devise creative ways to successfully accomplish Sandia’s tech transfer mission.

Updegraff’s success can be credited in part to her non-traditional background. She earned a bachelor’s degree in chemical engineering and worked in the pharmaceutical industry before becoming interested in patent law through a friend and colleague. She decided to go to law school at the University of New Mexico when she moved back home to Albuquerque with her husband.

“My husband began his Sandia career, and I knew I wanted to work here in some capacity in the future,” Updegraff said. “It really is the gold-standard employer in the state. When I was hired into the licensing group, I discovered how broad Sandia’s tech portfolio is and how impactful transitioning these technologies outside the national laboratories can be to the nation.”

In her time at Sandia, Updegraff has led the way in updating licensing and tech transfer agreement templates, greatly streamlining the process.

She helped create Sandia’s new faculty loan program, which allows Sandia employees to work in both the Sandia and university environments under temporary loan arrangements and further develop technologies that have tech transfer opportunities.

Updegraff also assisted in the negotiation of a high-value license with a major electronics company for an entire portfolio of patents and worked closely with Los Alamos National Laboratory to get the TRGR Technology Readiness Initiative off the ground.

Among her biggest accomplishments is spearheading the creation and implementation of a copyright transfer program that makes it easier for Sandia staff to publish their advancements and technologies for the public good. Samantha said she’s delighted to be recognized but still has work to do.

“I hope to streamline or at least demystify partnership processes at Sandia, making it easier for industry, government, academia and other national laboratories to work with us,” she said. “The hope is to lower the barrier to entry and ensure more technologies can be transferred to external partners, especially those who haven’t partnered with Sandia or national laboratories before.”

State and Local Economic Development Award – TRGR Technology Readiness Initiative

The FLC is also recognizing the TRGR Technology Readiness Initiative and its success in moving technology developed at the national labs to market.

They’ve awarded it the 2024 State and Local Economic Development Award.

The program, created in 2020, allows New Mexico businesses that have licensed technology from Sandia and Los Alamos National Laboratory, or engaged in a Cooperative Research and Development Agreement, to receive up to $150,000 in technology maturation assistance from the labs to help ready products and services for the marketplace.

Almost $1.5 million in lab hours have been used over the last three years to benefit New Mexico businesses. As a result, 15 licenses and three new Cooperative Research and Development Agreements have been secured.

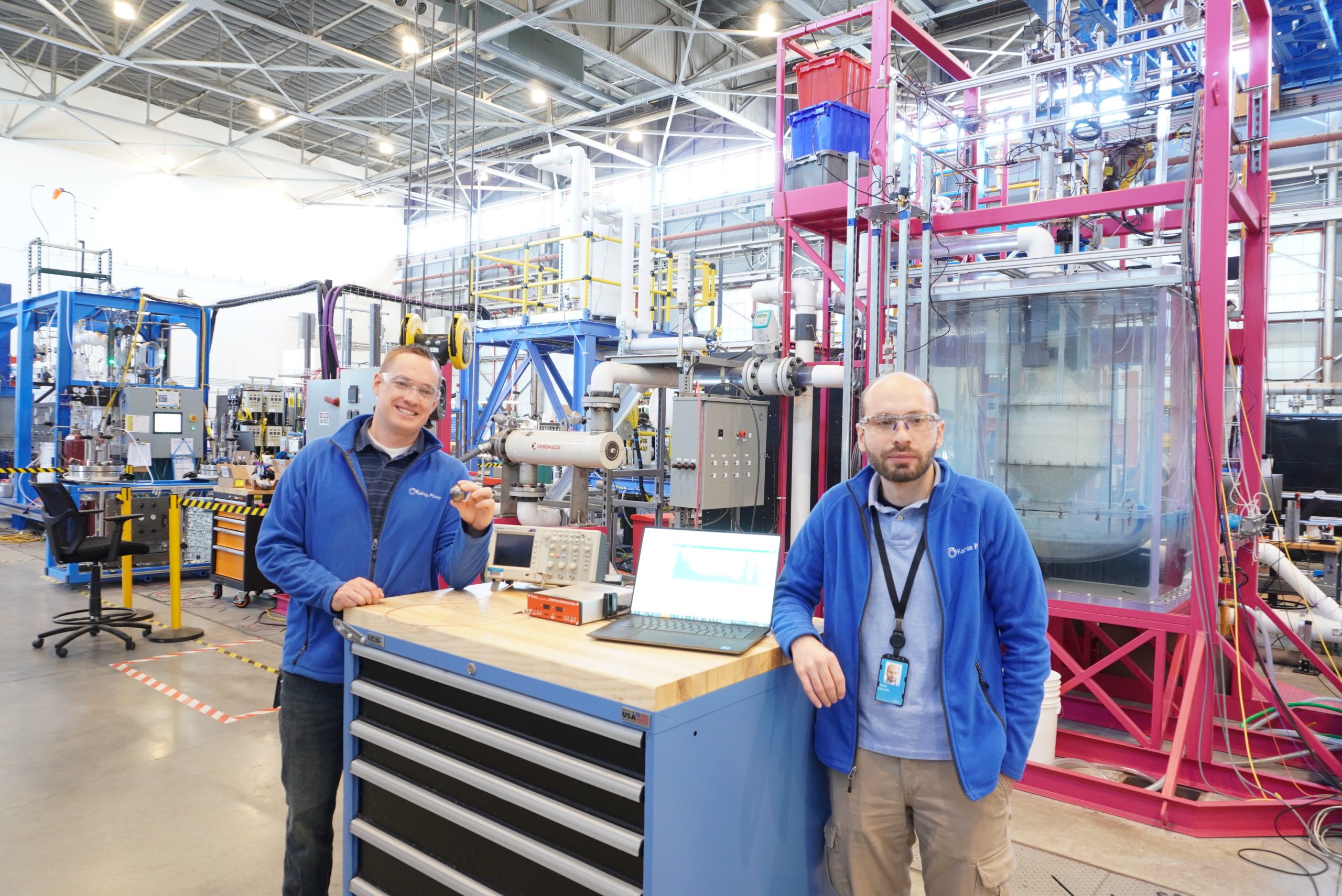

Among the success stories is that of Kairos Power, a nuclear energy engineering, design and manufacturing company. The company is commercializing a fluoride salt-cooled high-temperature reactor with a mission of enabling the world’s transition to clean energy.

Through TRGR, Kairos Power was able to access Sandia’s specialized equipment and expertise to develop a necessary sensor. They are now using engineering expertise at Los Alamos to further the design of a new facility.

The company’s testing and manufacturing facility in Albuquerque will support the design, construction and operation of the Hermes demonstration reactor in Oak Ridge, Tennessee.

The New Mexico Legislature has extended the tax credits necessary for the program through 2027.