Download 300dpi JPEG image, ‘cold_spray.jpg’, 148K (Media are welcome to download/publish this image with related news stories.)

ALBUQUERQUE, N.M. — You might call it the “science of splat.”

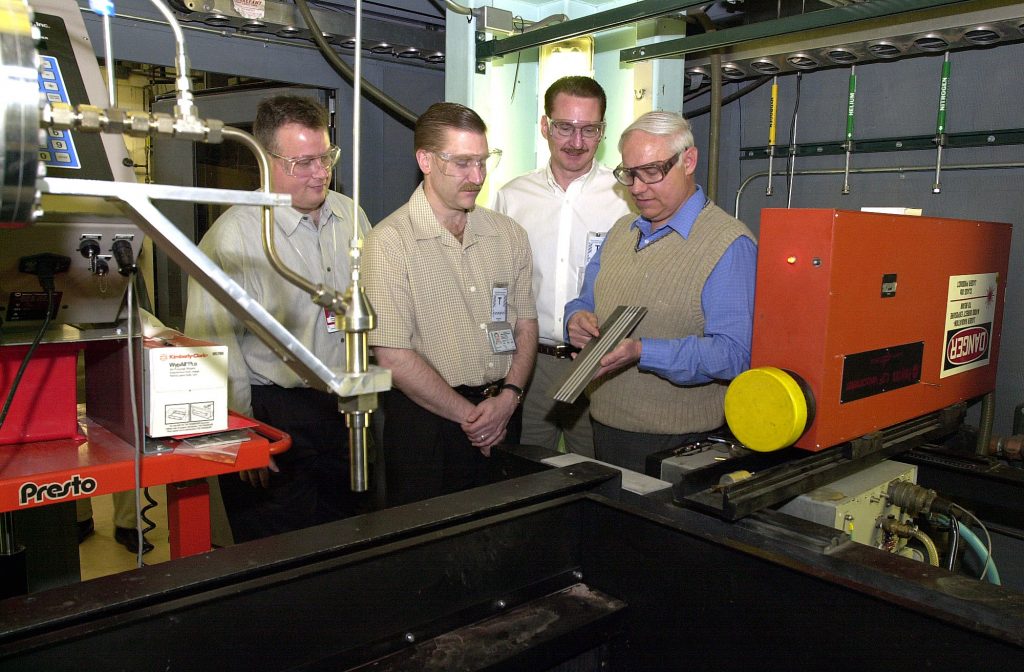

Working with a consortium of eight U.S. companies that includes automakers and aircraft engine manufacturers, researchers at Sandia National Laboratories are using experimental and computer-modeling capabilities to improve the world’s fundamental scientific understanding of an emerging manufacturing technique called Cold SprayTM.

Cold Spray involves injecting microscopic powdered particles of metal or other solids into a supersonic jet of rapidly expanding gas and shooting them at a target surface. When these 10- to 50-micron particles hit the substrate, they splat so hard they stick — like a bug to a windshield.

Consortium members plan to use new Cold Spray processes refined at Sandia, for instance, to create tough new coatings on car or aircraft engine components made from lighter-weight composites, or to deposit layers of conductive metals onto substrates for use as heat-tolerant under-hood automobile electronics.

Other possible uses of the technique include fabricating layer by layer low-defect small piece parts, joining chemically dissimilar materials with bonds that gradually transition from one material composition to another, and as a low-temperature alternative to welding.

“Cold Spray has some significant advantages as a coating and fabrication tool, and it provides capabilities not previously possible,” says Mark Smith of Sandia. “It’s a new enough technology that we don’t yet know all the possible applications, but it has the potential to make truly revolutionary changes in the way some products are manufactured.”

The consortium includes Alcoa, DaimlerChrysler, Ford Motor Co., The Jacobs Chuck Manufacturing Co., Ktech Corp., Pratt & Whitney, Praxair, and Siemens/Westinghouse.

Download 200dpi JPEG image, ‘Coldsprayvisit.jpg’, 688K (Media are welcome to download/publish this image with related news stories.)

Understanding splat

Cold Spray more appropriately might be called “room-temperature spray.”

Conventional “thermal spray” processes require preheating the sprayed materials so the particles are in a semi-molten state when they reach the substrate, allowing them to splash across the surface. But as the “splats” cool, they contract slightly, creating residual (stored) stresses or flaws at the interface that can cause defects later.

Cold-sprayed materials typically remain at or near room temperature until impact, slamming into the substrate so fast (500 to 1,500 meters per second) that a tight bond is formed without the undesirable chemistry changes and stresses associated with conventional processes.

Although the science behind this bonding process is not yet well understood, the researchers think the high-velocity impact disrupts thin metal-oxide films on the particle and substrate surfaces, pressing their atomic structures into intimate contact with one another under momentarily high interfacial pressures and temperatures.

Unlike thermal-sprayed materials, cold-sprayed materials experience little to no defect-causing oxidation during flight and exhibit remarkably high densities and conductivities once fabricated, the researchers have found. In addition, deposition rates comparable to traditional thermal spray processes can be achieved with Cold Spray.

“This is the logical conclusion of research thrusts in thermal spray technology during the last two decades toward faster-and-faster and cooler-and-cooler methods,” says Sandia’s Richard Neiser.

A variety of metals have been deposited at Sandia, including copper and aluminum, as well as several types of steel and nickel-based alloys. Even a few metal-ceramic composites have been successfully cold sprayed.

Cold Spray from a cold place

Cold Spray technology came to the U.S. in 1994, ten years after its Russian inventors first recognized its potential significance while conducting high-velocity wind tunnel tests at the Institute of Theoretical and Applied Mechanics of the Russian Academy of Sciences in Siberia.

One of its discoverers, Prof. Anatolii Papyrin, who holds the U.S. patent for Cold Spray, now works for Ktech in Albuquerque, which hopes to supply fabrication equipment to a broadened Cold Spray market.

Sandia is among just a few R&D institutions in the world successfully turning improved understanding of Cold Spray science into marketable technology, says Smith.

The Sandia research team is experimenting with varying materials, particle sizes, and impact velocities and examining gas dynamics, plastic deformation during splat-to-substrate impact, spray nozzle configuration, splat patterns, and bulk fabrication processes.

New industry inquiries about design and manufacturing possibilities are arriving at a steady pace, he says.