ALBUQUERQUE, N.M — When a SWAT team trains multiple times a week, running repeated live-fire drills, the noise can be intense. Even with premium hearing protection, the sound and pressure can damage hearing over time, contributing to traumatic brain injuries for officers and disorienting civilians nearby. If only there were a way to curb that danger.

Those kinds of problems are exactly what the New Mexico Small Business Assistance program has helped tackle for 25 years with support from Sandia National Laboratories and, since 2007, Los Alamos National Laboratory.

The program, created in the year 2000, helps small businesses solve critical challenges by providing technical assistance and expertise that they don’t have access to anywhere else, at no cost to them.

This year, two of the businesses Sandia helped aim to make the nation safer with their products: Ridgeline Engineering and Manufacturing, which is working to reduce hearing damage from firearms, and Aperi Computational Mechanics Consulting, which is making critical engineering simulations faster and more affordable.

Ridgeline Engineering and Manufacturing

When Matias Roybal and his wife started Ridgeline Engineering and Manufacturing in 2018, the goal was to use his mechanical engineering background to build a product they could, in all ways, call their own.

“After college, I went right to work as a performance development engineer and have worked in the automotive, defense and aerospace industries,” Roybal said. “I wanted to develop my own product and own the whole process, from design to finish.”

With his expertise in mechanical and structural design and additive manufacturing, or 3D printing, Roybal started building a quieter firearm suppressor.

Protecting First Responders

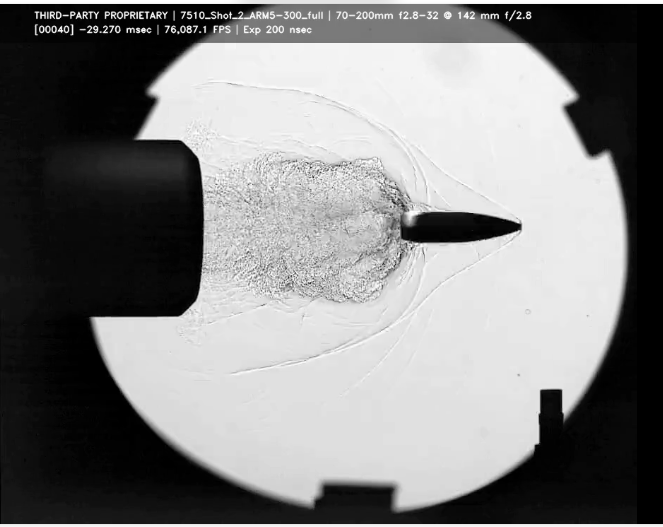

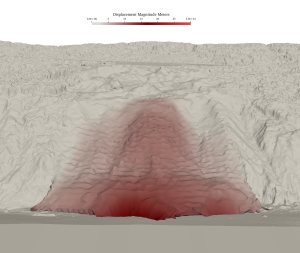

gas flow rates inside the suppressor. (Photo courtesy of Ridgeline Manufacturing) Click on the thumbnail for a high-resolution image.

“A big motivator is to protect the hearing of first responders like police officers and the military, as well as innocent bystanders,” Roybal said.

Roybal, who grew up in Mora, New Mexico, knew the basics of firearms and the dangers of hearing loss because of his hunting and shooting experience, but when he delved deep into the industry and partnered with a local SWAT team member, he learned just how significant the impact is.

“When you have 25 guys on a team and you are training multiple days a week, running five-shot drills per person, you all of a sudden have a lot of sound, a lot of pressure and are heavily exposed,” Roybal said. “While they are wearing premium hearing protection, you still get concussive impulse that causes hearing damage or even traumatic brain injuries. What we are trying to do with this product is take a problem in the industry and eliminate the occupational hazards.”

Roybal also wanted to consider bystanders who may find themselves exposed to gunshots unexpectedly.

“When a SWAT team goes into a building and they must discharge a firearm, there are sometimes civilians. People’s ears are ringing. It’s difficult for everyone involved and puts officers and civilians in danger,” Roybal said. “We’re trying to reduce that sound, get rid of that concussive force and pressure. It helps the officer as they try to communicate with people to get them out safe.”

Ridgeline Engineering and Manufacturing worked to build a suppressor they believe can better attenuate frequencies that cause hearing damage. But having a product in hand was just a first step.

Partnering with Sandia

That’s when Roybal and his team turned to Sandia and NMSBA for help. They needed to test that suppressor.

“They needed high-fidelity acoustic recordings that required specialized, high-precision and calibrated equipment,” said Michael Denison, Sandia acoustics and vibration engineer.

That is not something a small company like Ridgeline usually has access to. With the NMSBA program, they did.

It also gave them access to Denison’s expertise and that of lab technologist Stephen Aulbach, who has extensive outside firearms experience.

Ridgeline and Sandia worked together for two years conducting sound tests. The tests were designed to not only record the sound the suppressor made, but the potential impact to everyone within hearing distance.

They placed microphones to the right and left of the muzzle, near the shooter and downrange, and recorded the sound at each point and then analyzed the data.

“The cool thing about this project is that most suppressor manufacturers only care about sound pressure level,” Denison said. “We looked further into how the sound wave affects the human ear. We used modeling techniques that the Army Research Lab developed to figure out how certain suppressors will be more hearing safe. That is harder to quantify than simply measuring sound pressure levels.”

The team, which also included Sandia engineer Chad Heitman, used Sandia’s access to high-speed video and image equipment and diagnostics to show exactly what was going on inside the suppressor during firing.

“We built a suppressor with a clear case that showed the airflow so that we could see exactly what was going on inside the suppressor when a shot was taken. We were able to analyze each movement and action taking place,” Roybal said.

That enabled the Ridgeline team to make necessary changes and create a better product, all the while consulting those with firsthand experience, including law enforcement officers, a retired Special Forces colonel and soldiers at Fort Carson and Fort Bragg.

The end picture

Ridgeline’s suppressor is now on the market, but the team said they will keep working to make it even better.

“Building a safer environment for those impacted by firearms is important to this team,” Roybal said. “The reason that we are using this high-fidelity data is because we care about the end user. We’re not chasing money. We have a good product, but a good engineer knows as soon as a product goes out the door you can make it better.”

Denison said he looks forward to working with Ridgeline again.

“This project was a little outside the box for me,” he said. “It was a good way to exercise some of my other expertise that I don’t use daily during my regular job.”

It’s also a good way for staff like Denison to share their expertise with small businesses.

“We have advanced and unique capability at Sandia and it’s nice to be able to find ways to benefit the community and perform the work I love to do for people who benefit the most from it.”

Aperi Computational Mechanics Consulting

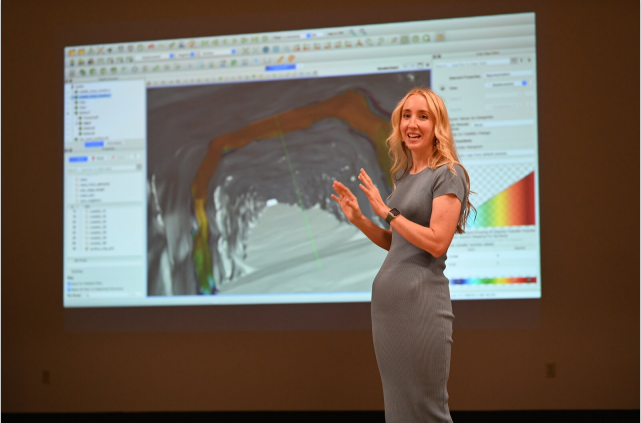

NMSBA’s impact is not only limited to physical products. In 2024, the NMSBA program and Sandia were also able to help a young software engineering company make a big impact. Aperi Computational Mechanics Consulting was founded in 2023 by Megan Ford to make engineering simulation cheaper.

Some of its applications include modeling the movement of underground soil such as nuclear waste storage tunnels or landslides and predicting their long-term stability.

“There is a need to understand collapse in tunnels that occurs over many years, but it’s hard to get test data of that,” said Aperi Chief Strategy Officer Kurtis Ford.

Aperi aims to make those simulations quicker and less expensive. That is where Sandia and the NMSBA came in.

“At Sandia, we have a bunch of resources that have been developed over many years for the mission-related work,” said Alan Williams, the Sandia computer science engineer who collaborated on the project. “We have similar applications and code libraries that provide the data structures and algorithms that allow them to do their calculations at a much faster pace.”

Making calculations faster

Williams said it has to do with the ability to process simulations on a graphics processing unit, or GPU, instead of a central processing unit, or CPU.

“It’s like the graphics processor on a computer; nearly every computer has one or more CPUs that do set value calculations like arithmetic,” he said. “But displaying pixels and rendering colors on your screen is best handled by a GPU, which is very fast and highly parallel. It can render millions of pixels and update them many times per second. What we can do with our simulation libraries is use the GPUs’ power to do our engineering calculations super-fast. That is what Aperi was looking for.”

Aperi has been able to do its simulations 150 times faster.

“That resource and expertise is not readily available to businesses like ours,” Ford said. “Without help from Sandia, it would have cost us $2 million to $3 million and would have taken a couple of years because we would have had to learn all the codes and libraries on our own. With Sandia, we knew what we needed, reached out to the place that has the expertise, and got it done quickly.”

Mutual Benefit

The NMSBA partnership has also brought something to Sandia.

Williams said the code libraries that Aperi used were still being built.

“What we did with the NMSBA grant is build some enhancements and developments that are specific for Aperi applications that also helped improve capabilities for internal Sandia applications,” he said. “It was a pooling of resources that turned out to be mutually beneficial.”

Williams said these improvements have also helped Sandia make better use of El Capitan, currently the world’s fastest computer, at Lawrence Livermore National Laboratory.

Aperi meanwhile, continues to grow. Ford said the NMSBA program work proved to be the company’s first big win, helping it earn three Small Business Innovation Research grants and the NMSBA Honorable Speaker Ben Lujan Award for Small Business Excellence.

The company is now working on detailed models of collapsing materials such as foam used in helmets and cars. They also hope to carry on the relationship with Sandia.

“It’s been a really positive experience,” Williams said. “It has been a more tangible benefit to see how you’ve helped a small business. You can feel their excitement when their code speeds up or does something new, so it’s been exciting and rewarding.”

About the NMSBA program

The NMSBA program started at Sandia in 2000 in response to the State of New Mexico Partnership with Small Business Tax Credit Act. The act is designed as a rural economic development program that allows up to $40,000 in annual assistance to companies located outside of Bernalillo and Santa Fe counties. Companies within Bernalillo and Santa Fe counties are still eligible but at a lower rate of $20,000 since they are in an urban area.

Since its inception, the NMSBA program has provided more than $89.8 million in assistance to 3,410 companies in all 33 counties.