ALBUQUERQUE, N.M. — Sandia National Laboratories and eight other companies and research organizations will collaborate to advance a distributed power system that can produce cleaner, more efficient electricity.

The memorandum of understanding focuses on the development of a fossil-fueled energy system based on supercritical carbon dioxide (S-CO2) Brayton cycle technology.

Organizations signing the memorandum with Sandia are Peregrine Turbine Technologies and its subsidiary PTT Distributed Energy Systems of Wiscasset, Maine; Vacuum Process Engineering of Sacramento, California; Mid-South Engineering of Hot Springs, Arkansas; and four partners from Huntsville, Alabama, CFD Research Corp., the U.S. Space & Rocket Center at NASA’s Marshall Space Flight Center, Government Energy Solutions Inc. and the Energy Huntsville Initiative.

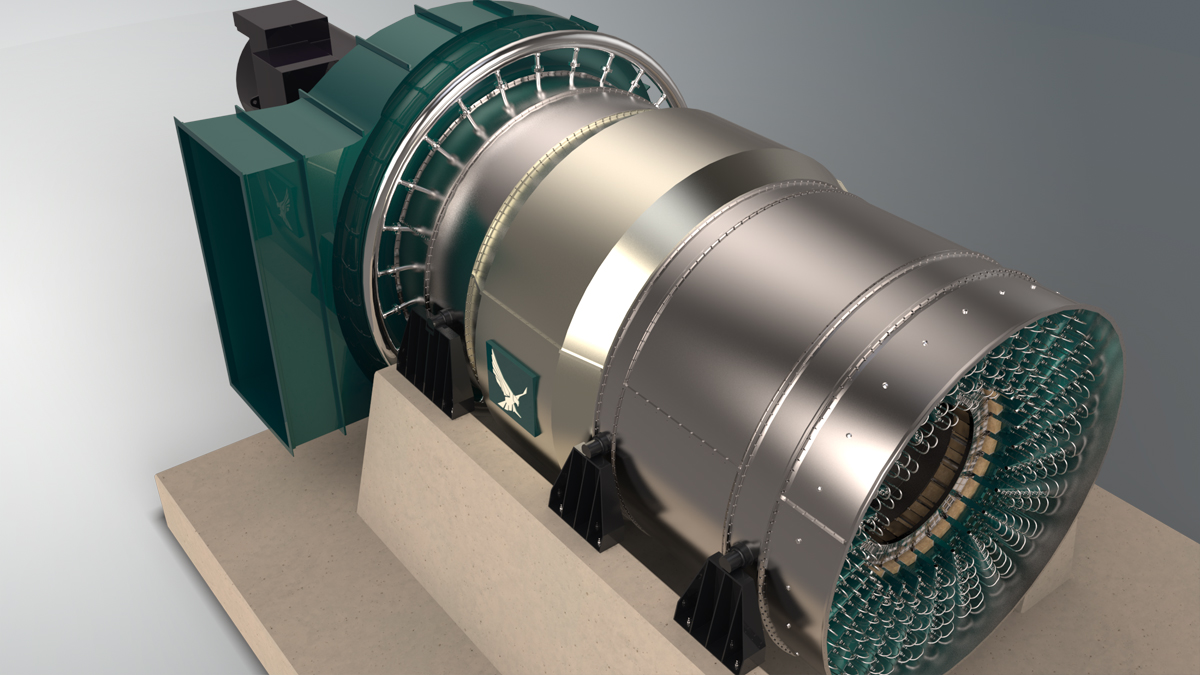

Sandia’s Brayton Lab in Albuquerque is the only S-CO2 research facility of its kind. The partners plan pilot testing there using a gas turbine engine based on a 6-megawatt energy-generating system developed by Peregrine Turbine Technologies. A second prototype engine would likely be tested at the U.S. Space & Rocket Center.

“This is the first large collaboration to identify partnerships that will take the Department of Energy’s lab-scale technology and accelerate its development to commercial industry deployment of a highly efficient, low carbon emission, electrical power generator,” said Gary Rochau, manager of Sandia’s Advanced Nuclear Concepts Department.

The agreement allows the organizations to work easily together to accomplish similar goals: advancing the commercialization readiness of the supercritical carbon dioxide Brayton cycle technology, providing world-class testing and analysis and encouraging the establishment of U.S.-based, high-value technology and manufacturing jobs.

The term “supercritical” refers to the semi-liquid state of carbon dioxide when it is above its normal critical temperature and pressure, allowing S-CO2-based systems to operate with high thermal efficiency.

Improving power generation technology is part of Sandia’s mission to strengthen national energy security, Rochau said.“The supercritical carbon dioxide Brayton cycle can replace steam systems in a smaller size with higher efficiency, lower cost, lower emissions and with distributed power generation, reducing the burden on the national power grid,” said Rochau.

Rochau said supercritical carbon dioxide Brayton cycle technology could bring about large-scale improvements in production across most energy sectors, especially solar, nuclear and gas turbine. Potential economic and environmental benefits include reduced fuel consumption and emissions and the ability to generate power from a variety of heat sources, he said.

Peregrine Turbine Technologies is developing a power generation turbine engine that uses super critical carbon dioxide as a working fluid. CEO David Stapp said it could be 30 percent to 60 percent more efficient than current technology.