Download 300dpi JPEG image, ‘mulch-19.jpg’, 640K (Media are welcome to download/publish this image with related news stories.)

ALBUQUERQUE, N.M. — A method that uses roughly only one-hundredth the fresh water customarily needed to grow forage for livestock may leave much more water available for human consumption, as well as for residential and industrial uses. As a byproduct, it also may add formerly untapped solar energy to the electrical grid.

The method for lessening water use is being tested by 42 wireless sensors being installed in a forage-growing hydroponic greenhouse built barely a stone’s throw from the Mexico border under the supervision of the National Nuclear Security Administration’s Sandia National Laboratories, a U.S. national security lab.

Sandia is interested because, says lab researcher Ron Pate, “Disputes over water are possible, if not likely, causes for war in the 21st century.”

Echoes Sandia’s director for Geoscience and Environment Peter Davies, “A large proportion of freshwater usage around the world is agricultural. The ability to reduce the amount of water needed for it and thus lessen the possibility of international conflict is extremely important to the security of the United States and the world.”

The potential savings in water is particularly important in New Mexico and the American Southwest, Mexico, water-parched regions like the Middle East, certain lands between India and Pakistan, and even northern China, where underground water supplies used intensively for agriculture are dipping lower, says Pate. “In all these places, the majority of water use is for irrigated agriculture rather than direct human consumption and other productive uses.”

Download 300dpi JPEG image, ‘racks_21.jpg’, 732K (Media are welcome to download/publish this image with related news stories.)

Preliminary indications are that hydroponic greenhouses in New Mexico, for example, could reduce the current 800,000 acre-feet of water to 11,000 acre-feet to produce an equivalent amount (dry weight) of livestock forage, and do this on less than 1,000 acres instead of 260,000 acres — the current amount used for New Mexico production of alfalfa. Eighty percent of New Mexico’s water use is agricultural. Over half goes toward growing forage. Most of this is alfalfa.

Similar conditions of water use exist in many places in the world.

Conventional farming methods in arid regions lose huge amounts of water through evaporation and over-absorption by soil. Over time, this can also result in soil salination and loss of agricultural productivity. Neither are factors in hydroponic greenhouses, which do not require high-quality arable land to function in the first place.

Hydroponic greenhouses recently built in the State of Chihuahua have been used by Mexican ranchers during the current drought to grow feed to preserve their herds. However, technical questions regarding optimizing the actual amount of water saved, evaluating the nutritional value of the forage, as well as determining optimum light for best growth, have yet to be determined. Conditions for economic viability also need to be more fully explored.

Thus, Mexican researchers take a keen interest in the U.S. project, taking place just north of the U.S./Mexico border in Santa Teresa, N.M., a few miles west of El Paso. Led by researcher Hector Gallegos and hydroponic forage system fabricator Francisco Aguirre, they have made frequent visits from Ciudad Chihuahua — a drive of about 3.5 hours — to help in the design, construction, and implementation of the project.

“The difference [between our projects and this one] is the sensors Sandia is installing to check things there,” Gallegos said in a telephone interview from Chihuahua. “Normally we only use a humidity sensor to know when to run our irrigation.”

The Sandia-placed sensors and computer simulations will tell researchers how to grow crops still more efficiently, he says.

“We need to review the amount of water used in the greenhouse; the only way to do this is to determine accurately the amount needed at every step.” Also, he says, the Mexican tests used only readily available wheat and corn; the Sandia tests include, in addition, triticale, sorghum, barley, and oats.

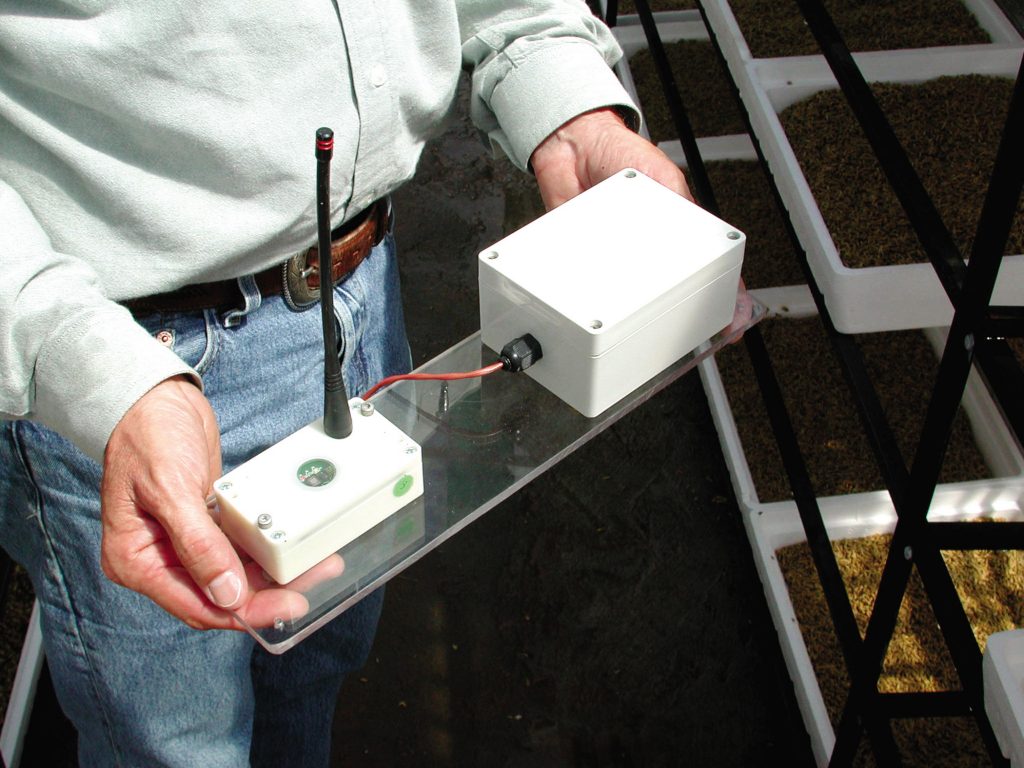

Download 300dpi JPEG image, ‘device-17.jpg’, 544K (Media are welcome to download/publish this image with related news stories.)

The nutritional quality of the hydroponically grown plants will be determined by Clint Loest, a professor of animal nutrition at New Mexico State University, whose lab will compare results of feed testing with the animals’ actual requirements.

“This is definitely unique in the animal forage area,” he said. “If we can get the animals to perform just as well on greenhouse forage, that would be an incredible advance. It would be such a breakthrough that we might even give up a little performance if it’s going to save so much water.”

The difference between traditional agriculture and hydroponics is that the greenhouse plants do not draw nourishment from the earth. In this experiment, they rely on the nutrition present in seed that is germinated, precisely watered, and harvested after about 10 days of growth. Thus, more seed is required for the production of an equivalent amount of forage (compared to that traditionally grown in open fields), but with far less water use.

The hydroponic greenhouse, also known as “protected agriculture” or “controlled-environment agriculture,” also controls and modifies light reaching the plants. Experiments will reduce light intensity and restrict certain frequencies, using a variety of shading mechanisms to avoid overheating and improve plant growth.

The “speaking plant” approach

Gene Giacomelli, director of the highly regarded Controlled Environment Agricultural Program in the Agricultural and Biosystems Engineering Department, University of Arizona, says he appreciates Sandia’s involvement because “Sandia has advanced technologies that can be added to lower the cost of traditional environmental sensing.”

In addition to the wireless technologies currently being installed, Giacomelli mentioned a possible “speaking plant” approach, where very small, lightweight, inexpensive sensors are put directly on each plant to monitor the plant’s water status, temperature, and growth rate.

“We envision these [futuristic] sensors linked together [via wireless communications], possibly on every plant, so the plant tells the control system directly what it needs, instead of merely monitoring air around the plant. The plant may have other needs these [more distant sensors] don’t tell us. This will be the highest tech going.”

Such sensors are being developed at Sandia for other types of surveillance. Giacomelli complimented Labs researchers because “They recognized that when you apply technology to a biological system, you can’t just plunk it in there without having biological expertise to apply the high tech in a practical way.”

The way it works

The dense array of sensors in the 8m x 18m (26 ft by 59 ft) greenhouse will monitor light, temperature, relative humidity, and air pressure. The data, collected every few minutes, will be sent by phone line to a remote computer for analysis. “We expect that the [greenhouse] system will not be as slow-moving or spatially homogeneous as one might think in terms of environmental change,” Ron says. “Every time the water system pops on, the local temperature around the plants drops relatively quickly.” Water sprays from quarter-inch nozzles for 20 seconds into plants growing in a series of plastic trays stacked on metal racks, whenever a humidity sensor or a back-up timer trips a control circuit. To lessen labor and also protect against mold, the researchers are exploring the development and use of trays that themselves would be edible by livestock, thus making washing and sanitizing trays unnecessary. Such tray material could also add nutrition content to the overall forage product, making it a more balanced ration for the livestock. Consumption of water, seed, and labor are also being monitored.

“We want to be aware of microclimate variances,” says Pate. “We want to know how feed grows from changes in temperature and location and time of watering. That will help us modify the design and operation of the greenhouses.”

The solar way

Experiments are also being planned to use the blocked light to create another asset: solar-generated electrical power. (Greenhouse pumps, timers, and sensors are already powered by freestanding solar modules that change light into electricity, which is then stored in batteries for nighttime use and during cloudy weather conditions.)

“Greenhouses could be a solar source,” says Sandia researcher Vipin Gupta, “because sunlight has to be filtered in arid areas to prevent crop damage because it is too intense. The challenge is to create reliable, effective materials to use that part of the spectrum the plant is not interested in using to produce power that can be put on a grid as well as operate the greenhouse.” Commercial interest has been expressed in this project.

Vipin is currently based at the University of Texas at El Paso’s Materials Research Technology Institute and serves as a local focal point for the project. Sandia technologist Ed Baynes is based in Las Cruces and provides technical support for the greenhouse. Sandia/California researchers Nina Berry and Jesse Davis, with two summer student interns, are helping implement the wirelessly networked sensor array and cell phone data link, expected to be installed in mid-September.

The idea of a bi-national laboratory

While agricultural tradition, cultural factors, and economic realities make immediate implementation of hydroponic greenhouse methods for livestock forage doubtful, the project should produce data useful for when drought is seriously upon us.

The project also serves as an opening wedge for another entity: a joint laboratory with Mexico to work on border-related scientific problems, says Gerry Yonas, Sandia Principal Scientist and director of the Labs’ Advanced Concept Group (ACG), “Because the ACG looks to future global security issues, we advanced the idea of a bi-national lab between Mexico and the U.S. to deal with border issues that have a potential for conflict. This [greenhouse] project is the first fruit of that idea.”

Says Jessica Turnley, a Sandia consultant and director of the Sandia-spun-off Bi-National Sustainability Laboratory, “We look forward to using the greenhouse facility to work with Sandia and with scientists and the communities on both sides of the border to develop technologies to help improve the quality of life.”