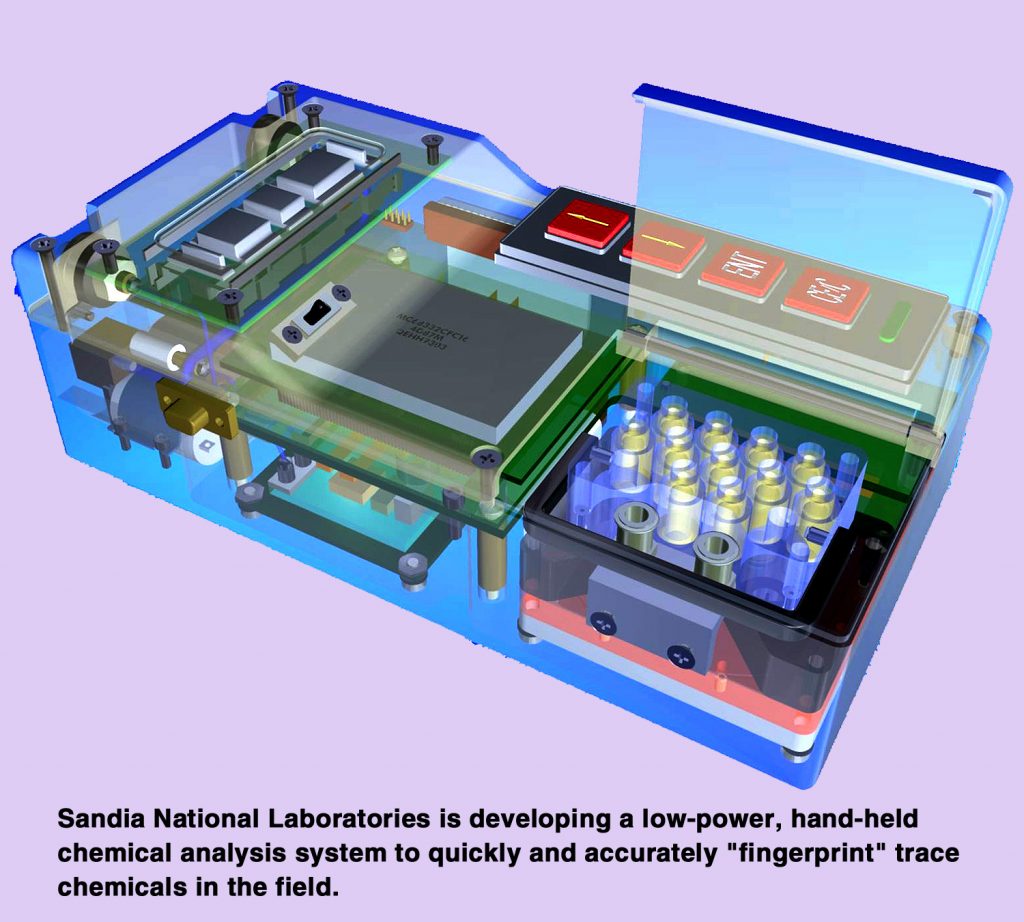

Download 300dpi JPEG image, ‘device.jpg’, 80K (Media are welcome to download/publish this image with related news stories.)

SAN FRANCISCO, CA. — A powerful new portable chemical analysis device that fits in the palm of a hand is being developed by the Department of Energy’s Sandia National Laboratories and will be presented Sunday, March 26, at the annual meeting of the American Chemical Society.

“People have been talking about this for a long time,” said chemist and presenter Christopher Bailey, who works at Sandia’s Livermore, Calif. lab. “It integrates all the pieces.”

Sandia researchers demonstrate their device’s capabilities by analyzing a complex mixture of explosives. A chemical signature — or fingerprint — is created by separating constituents with chromatography, a process of moving the mixture through separation channels containing a variety of materials. The materials retain constituents to different extents, so they appear sequentially in separate batches at the end of the channel. From an initial mixture injected manually into a reservoir, the system automatically distributes a fraction of a droplet (a tenth of a nanoliter) to channels thinner than a human hair. Within about a minute, a small display screen flashes the name and quantity of the components. The technique detects compounds at the part per billion level. This process, which involves shrinking and knitting together disparate systems, replaces standard chemical analysis methods normally performed with bulky equipment on a laboratory countertop.

Quick, sensitive and selective chemical analysis on a chip, not tethered to large lab equipment, is expected to become affordable and widespread through future developments. Researchers envision automated field-portable systems producing results in real time that could sniff out land mines, signal food quality, check environmental safety for emergency responders who suspect chemical or biological hazards, detect pollutants near their source, perform medical diagnostics at a bedside, screen new pharmaceutical drug candidates or optimize industrial processing.

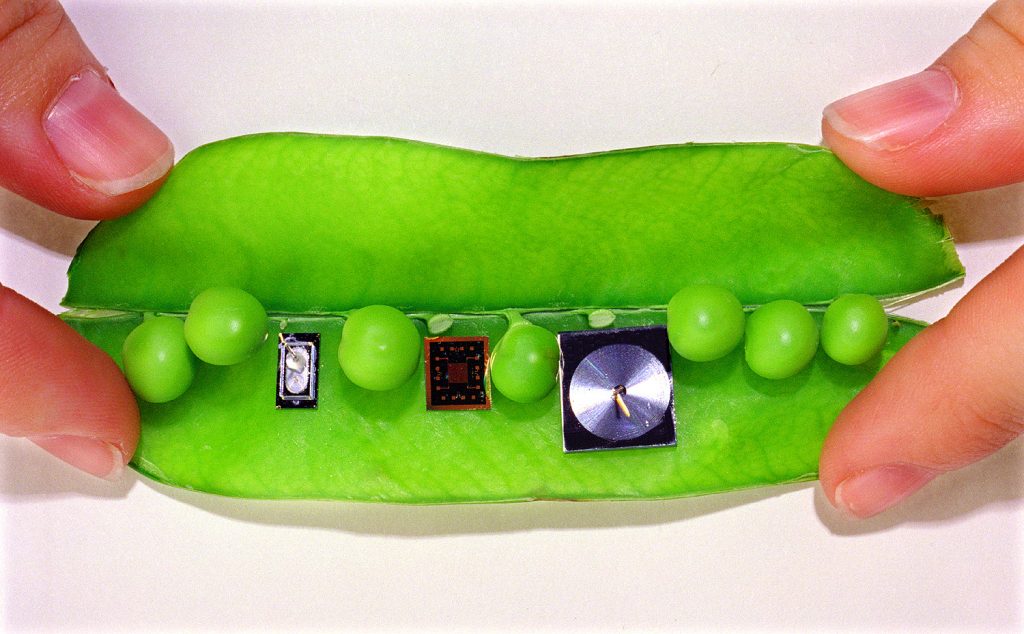

Download 300dpi JPEG image, ‘peapod.jpg’, 268K (Media are welcome to download/publish this image with related news stories.)

The hand-held chemical analysis device includes a compact power source and solid-state relays that regulate and switch energy drawn from camera batteries. Built-in lasers and photodiodes, fabricated in a bit of semiconductor that would fit easily into a pencil eraser, read results in each of three channels. Results are analyzed by an internal microprocessor, which also automates the separation. To program the microprocessor, users toggle through a menu of commands using four buttons on a touch pad.

Designing the interface between the microfabricated components and the macroscopic world was just one of the challenges that the team faced, Bailey said. In development is a second unit designed to safely spot trace indicators of biological toxins.

Other members of the research team are presenting related results Sunday evening. They’ll describe a novel way to create high pressure and flow rates to route liquids through injection and separation channels without moving parts.

The narrow channels (10 – 100 microns wide) are packed full of small particles of silica. The surfaces of the particles and channel walls efficiently drive buffered solutions forward when high voltage is applied. The researchers have produced high pressures and significant fluid flow rates. This process, an electrokinetic pump, permits creation of pressures exceeding 9,000 pounds per square inch (psi).

Holding up a small square of glass containing a narrow channel, presenter Don Arnold of Sandia remarked that in comparison to other pumping schemes on chips, “We’re getting orders and orders of magnitude more performance. It’s limited by the connector — I can generate pressures on a chip of 10,000 psi, but blow the connector. We’ve generated pressures to the point where the glass breaks from mechanical failure.”

Not only can fluids be easily moved on a chip with electrokinetic pumping, but it can also generate enough hydraulic force to potentially actuate a host of microsystems, such as moving microsurgical tools on the end of a catheter, said Sandia researcher Phil Paul.