ALBUQUERQUE, N.M. — Sandia National Laboratories researchers took home six R&D 100 Awards, one joint award with Los Alamos National Laboratory and one special award for 2023 in the annual international technical competition that includes researchers from universities, corporations and government labs.

“These achievements further Sandia’s mission and demonstrate the impact that innovative research and development like these endeavors have produced,” said Chief Research Officer Doug Kothe, associate laboratories director for advanced science & technology.

The R&D 100 Awards, in its 61st year, is a globally prestigious recognition of invention and innovation. It claims entries this year from 15 countries and regions and is sponsored by R&D World Magazine.

Honors go to researchers deemed to have developed the year’s 100 most outstanding advances in applied technologies, in the judgment of the magazine’s editors and expert panels.

The awards focus on practical impact rather than pure research and reward entrants on their products’ design, development, testing and production.

The winning applications were announced in late September.

The Sandia winners were:

Pre-Symptomatic Volatile Organic Compounds Detector of Seizure Events

Philip Miller, Matthew Moorman, Joshua Whiting, Haley Bennet, Jason Sammon, Alex Hare, Bryan Weaver, Kent Pfeifer, Gary Groves, Nathan Wolff and Gary Arnold (external collaborator)

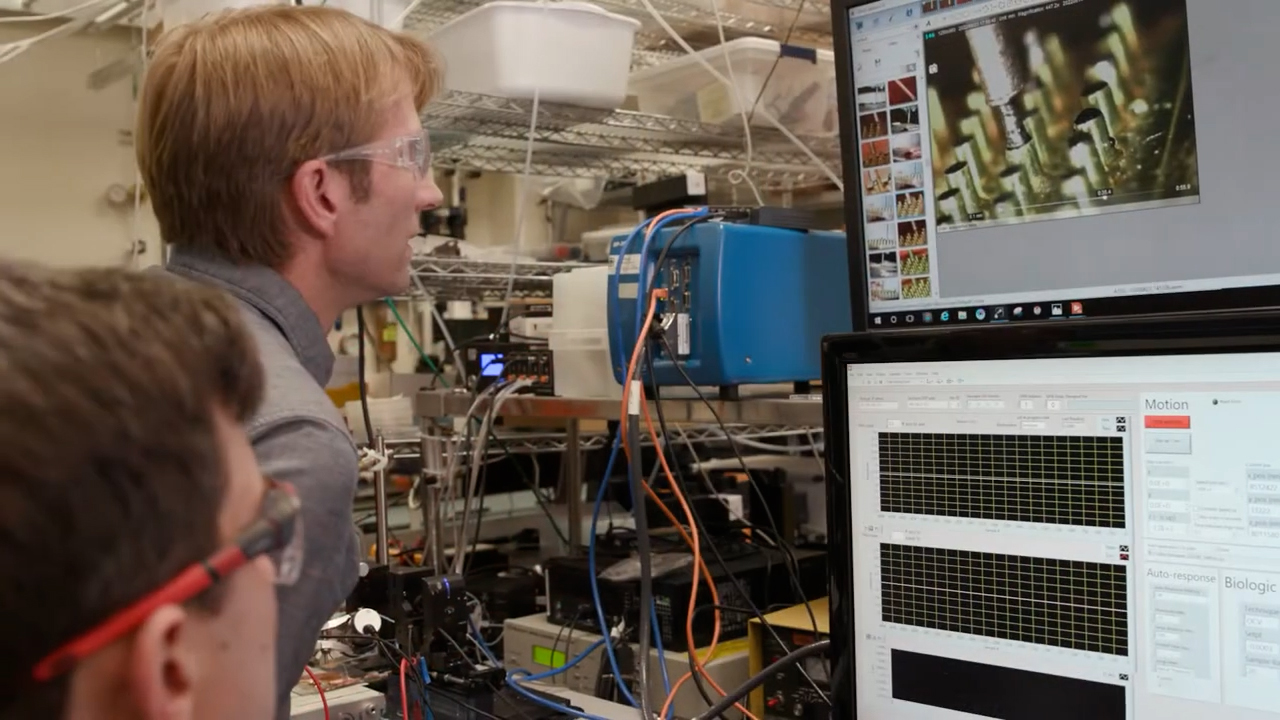

This invention improves the lives of people with epilepsy. The wearable detector identifies skin-emitted gasses that indicate an episode is imminent. A feat never before accomplished by technology — some dogs do it naturally, with the drawback that they have to be present at the right time — the detector’s pre-symptomatic warning enables the wearer to seek shelter and to communicate with family and healthcare providers before the seizure occurs. This dramatically lessens the stress of those formerly at the mercy of these unpredictable events.

The device when commercialized will function by constantly sampling gasses emitted from the wearer’s skin and analyzing them automatically without the wearer’s input or engagement. Upon detection of volatile organic compounds unique to seizures, the device will alert both the wearer and their care circle.

The instrument is currently comprised of several system devices made in Sandia’s silicon microfabrication facility. A chemical pre-concentrator collects and stores the volatile organic compounds. Chemical separation takes place in a two-dimensional micro gas chromatography device. Detection is performed with a miniature ion mobility spectrometer. When these components are combined at a system level, their total volume — about that of a mid-size novel —and weight — 1.5 lbs with battery — are amenable to being worn on the body.

This project has roots in MicroChemLab, Sandia’s first Laboratory Directed Research & Development Grand Challenge.

META Optics Studio

Ihab El-Kady, Denis Ridzal, Timothy Wilde, Edgar Bustamante, David Fitzpatrick, Ryan Chilton (external collaborator) and Mehmet F. Su (external collaborator)

META Optics is a software package built for the design, simulation and optimization of flat meta-surfaces, which are artificial structures used to engineer the light wavefront for enhanced focusing, phase correction and removal of aberrations. If designed correctly, a metalens can perform the function of a highly focusing, high-speed lens while being a fraction of its weight and absolutely flat. This has revolutionized the field of optical imaging and extended its possibilities by significantly reducing size, weight and power requirements while extending the imaging resolution to be well below the subwavelength limit. META Optics is the only known software capable of simulating a centimeter-sized meta-surface at nanometer resolution within a few hours.

The META Optics project developed out of the Metamaterial Science and Technology Laboratory Directed Research and Development Grand Challenge from 2009-2011.

Materials Learning Algorithms

Sivasankaran Rajamanickam, Attila Cangi (external collaborator), Normand Modine, Aidan Thompson, Jon Vogel, Adam Stephens and Lenz Fiedler (external collaborator)

The Materials Learning Algorithms is a software framework that uses machine learning to predict the electronic structure of materials. Electronic structure is fundamental for understanding virtually all molecular and material properties. The software enables these calculations at length and time scales that were previously unfeasible.

Density functional theory, for which the Nobel Prize was awarded in 1998, is the most heavily used approach for electronic structure calculations. However, the method is complex, expensive and limited to small scales because the amount of data increases exponentially with the number of chemical elements, thermodynamic states, phases and interfaces. Machine Learning Algorithms is focused on solving the limitations of density functional theory using machine learning.

The key questions that the sofware addresses are, “Can machine learning help accelerate these first-principle electronic structure calculations?” and “Can this be more scalable with respect to system size?” The methods developed in the framework answer both these questions in the affirmative.

Materials Learning Algorithms was primarily funded out of a Computing and Information Sciences LDRD project, “Accelerating Multiscale Materials Modeling with Machine Learning,” which ended in 2022.

Materials Data-Driven Design

David Montes de Oca Zapiain, Hojun Lim, Benjamin Greene and Taejoon Park (external collaborator)

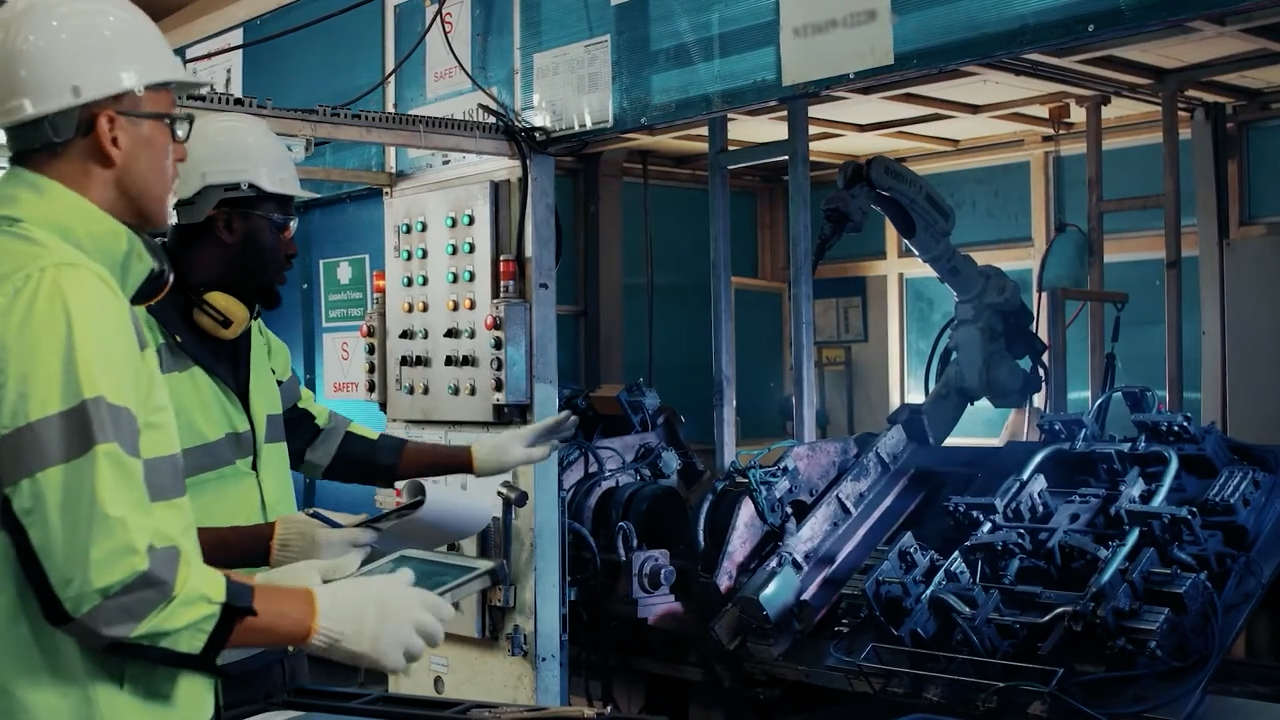

MAD3 is an innovative software that leverages the power of machine learning to modernize the forming and stamping processes of sheet metals. It predicts the parameters that characterize the directional mechanical behavior of a metal alloy 1,000 times faster than existing solutions. As a result, the software significantly reduces expensive and time-consuming forming and stamping trials.

More explicitly, metal alloys such as aluminum or steel used in various manufacturing processes like stamping and forming exhibit directional strength and formability that cause the metal to distort. The reaction, called plastic anisotropy, determines whether the material is capable of being shaped to the desired component fit and finish, and whether it will withstand the applied performance load. As a result, accurate predictions of the metal’s plastic anisotropy are crucial in major manufacturing and supported by automotive and aerospace metal manufacturers as well as suppliers.

However, the cost of characterizing plastic anisotropy has skyrocketed because characterization requires specialized equipment and significant technical expertise. The software uses state-of-the-art data-driven and machine-learning techniques to first extract a unique fingerprint descriptor of the metal alloy’s internal structure, then subsequently uses these descriptors to predict the plastic anisotropy parameters in an accurate and efficient manner.

These anisotropy parameters can be used to perform forming and stamping simulations with unprecedented accuracy since they incorporate the effect of the polycrystalline grain structure.

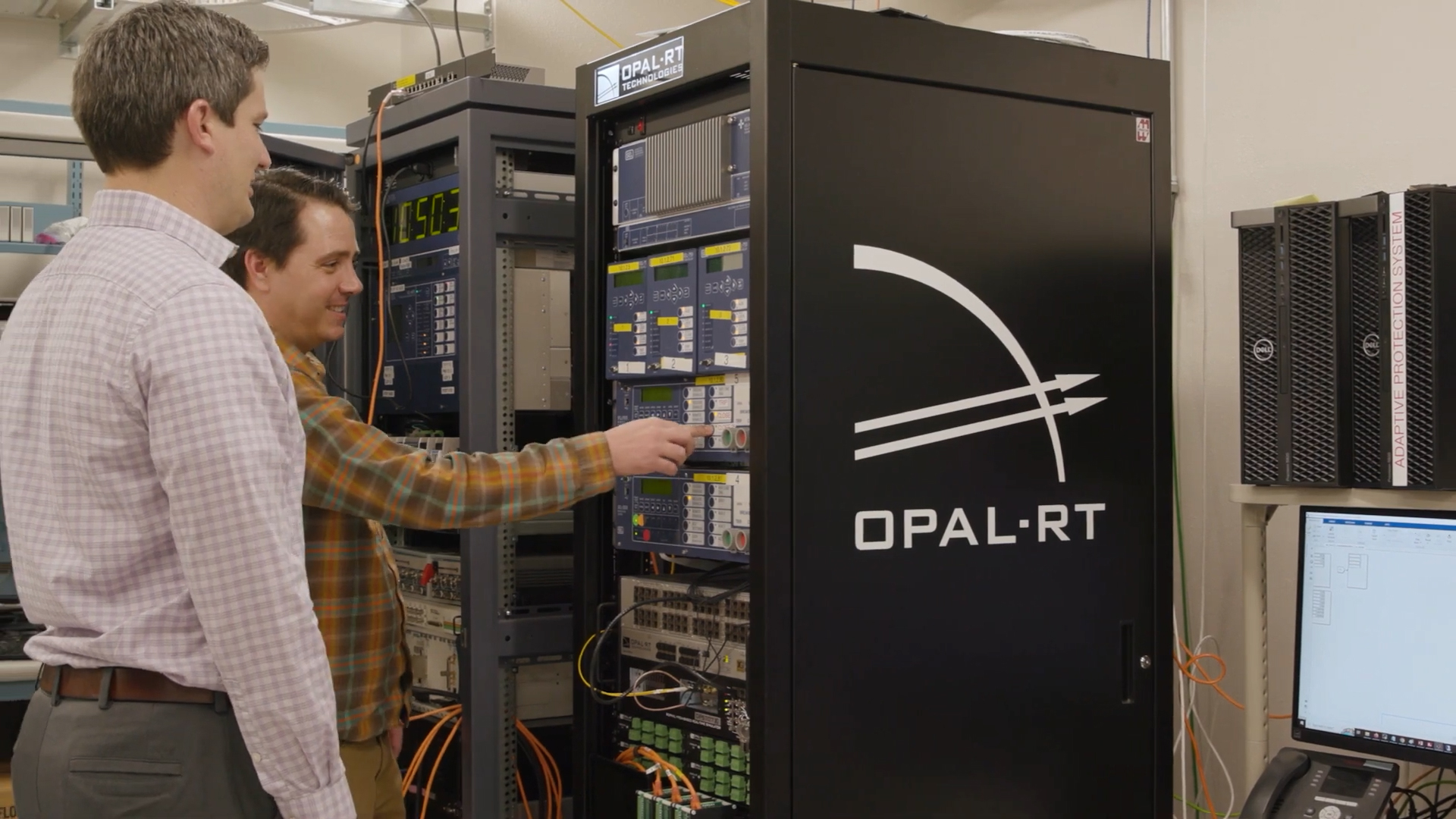

PowerModelsONM: Optimizing Operations of Networked Microgrids for Resilience

Matthew Reno, Trupal Patel, Adam Summers, Ronald Matthews and Dan Kelly

PowerModelsONM software optimizes networked microgrids for power restoration during blackouts and other extreme events. It is the only physics-based optimization software package featuring networked microgrids for modeling restoration of electric power distribution feeders.

Utilities can use PowerModelsONM to plan for networked microgrids to support rapid recovery during extreme-event-induced grid outages. Superior validation is achieved using utility data sets for software simulation and hardware-in-the-loop experiments. Sandia is a partner on PowerModelsONM with Los Alamos National Laboratory, National Renewable Energy Laboratory and National Rural Electric Cooperative Association.

Electro3D

Karl Walczak, Brian Perdue, Adam Cook, Jonathan Height, Jon Coleman, Jesse Duran (former Sandia intern), Jakob Graham Bates (former Sandia intern) and Garrett Williams (former Sandia intern)

Electro3D is an additive process that leverages fluidics with electrochemistry to produce high-quality materials and parts rapidly. The technology could serve many sectors, especially printed electronics, because materials such as copper can be printed at the room temperatures and pressures at which Electro3D performs.

The process also can be used to analyze and even build materials through an electrodeposition printhead that reduces mass transport losses. The printhead attached to commercial robots or 3D printing stages has the potential to be a more energy-efficient and economical pathway to generate materials and parts than currently available methods. The technology is scalable, deployable and has the potential to print multimaterials (metals, semiconductor, polymers) with rapid transition.

The custom printhead dramatically increases the replenishment rate of the electrolyte in the deposition area, which improves the uniformity and rate of the material deposited. The deposition is controlled by tuning the fluidics, current and voltage that drive the electrodeposition reaction. This information is fed into a feedback loop that moves the printhead based on real-time feedback of deposition conditions, which is critical to achieve the desired material properties and geometry of the part.

This work is rooted in “Advanced Manufacturing Techniques of Thermoelectric Modules,” a recent Laboratory Directed Research and Development project.